Solidification preparation method for aluminum oxide-based ternary nanometer eutectic/amorphous ceramic

An alumina-based and ternary technology, which is applied in the field of rapid solidification preparation, can solve the problems of difficulty in studying the effect of cooling rate and failure to obtain it, and achieve the effects of wide solidification rate range, high solidification rate and rich solidification structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

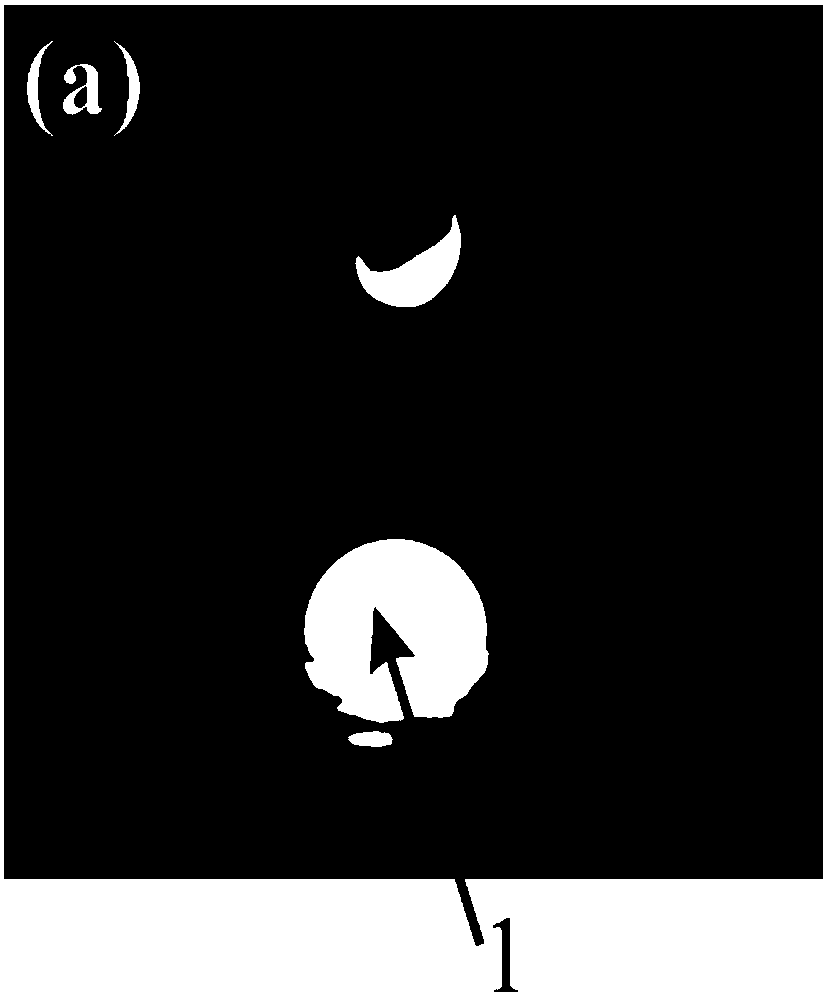

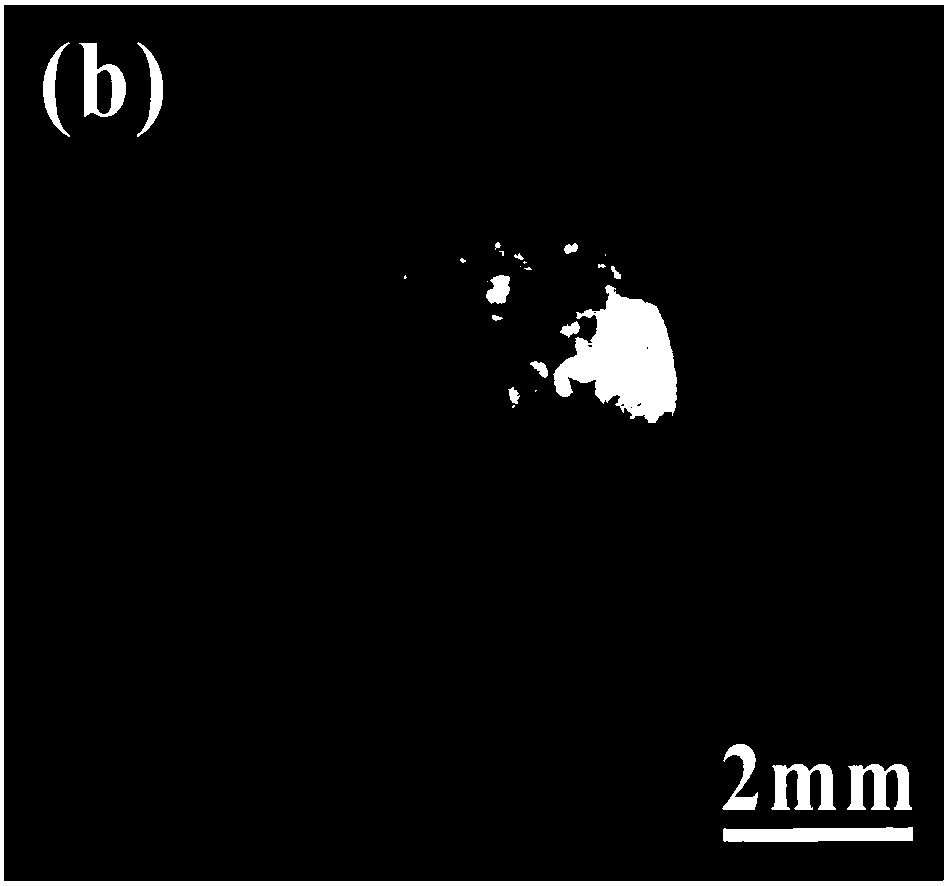

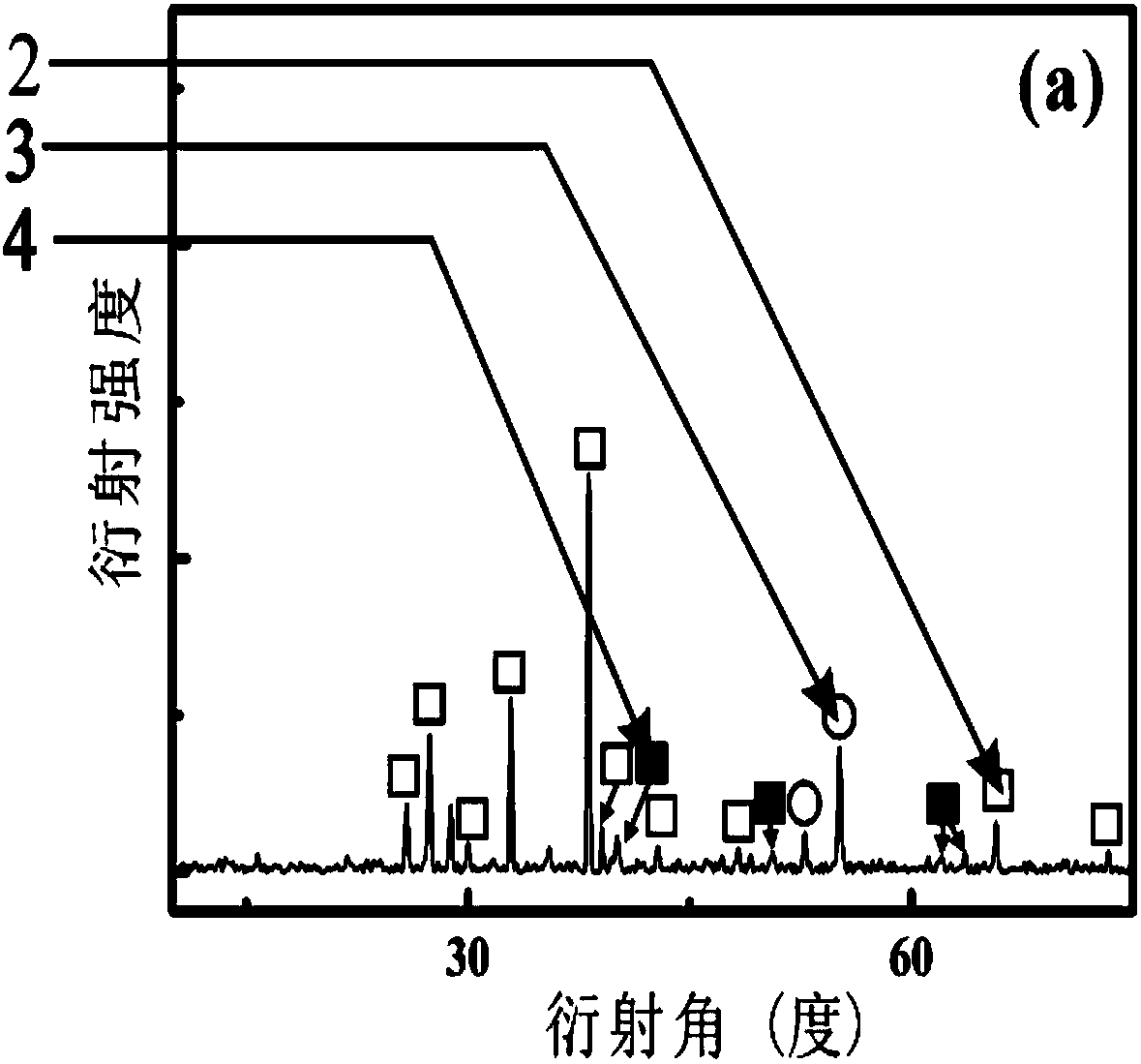

[0032] This embodiment is a method of melting samples in a laser levitation directional solidification zone and performing liquid metal quenching on falling melt droplets by surface tension effect to prepare alumina-based nano-eutectic / amorphous ceramic materials. This embodiment adopts this method to prepare Al 2 o 3 -Er 2 o 3 -ZrO 2 Ternary system nano-eutectic / amorphous ceramics, the specific process includes:

[0033] Step 1, Al 2 o 3 -Er 2 o 3 -ZrO 2 Preparation of ternary system eutectic component powders. Select Al with a purity of 99.99% 2 o 3 Powder, Er 2 o 3 Powder and ZrO 2 powder. According to Al 2 o 3 -Er 2 o 3 -ZrO 2 Al 2 o 3 -Er 2 o 3 -ZrO 2 Mix powder. Weigh 100g of the mixed powder obtained, and add 15ml of polyvinyl alcohol solution and 60ml of absolute ethanol to the weighed mixed powder, and use a ball mill to fully mix; the speed of the ball mill is 550r / min, and the ball milling time is 5h. Put the mixed powder into a drying ove...

Embodiment 2

[0039] This embodiment is a method of melting samples in a laser levitation directional solidification zone and performing liquid metal quenching on falling melt droplets by surface tension effect to prepare alumina-based nano-eutectic / amorphous ceramic materials. This embodiment adopts this method to prepare Al 2 o 3 -Y 2 o 3 -ZrO 2 Ternary system nano-eutectic / amorphous ceramics, the specific process includes:

[0040] Step 1, Al 2 o 3 -Y 2 o 3 -ZrO 2 Preparation of ternary system eutectic component powders. Select Al with a purity of 99.99% 2 o 3 Powder, Y 2 o 3 Powder and ZrO 2 powder. According to Al 2 o 3 -Y 2 o 3 -ZrO 2 Al 2 o 3 -Y 2 o 3 -ZrO 2 Mix powder. Weigh 100g of the mixed powder obtained, and add 10ml of polyvinyl alcohol solution and 50ml of absolute ethanol to the weighed mixed powder, and use a ball mill to fully mix; the speed of the ball mill is 500r / min, and the ball milling time is 3h. Put the mixed powder into a drying oven and...

Embodiment 3

[0046] This embodiment is a method of melting samples in a laser levitation directional solidification zone and performing liquid metal quenching on falling melt droplets by surface tension effect to prepare alumina-based nano-eutectic / amorphous ceramic materials. This embodiment adopts this method to prepare Al 2 o 3 -Gd 2 o 3 -ZrO 2 Ternary system nano-eutectic / amorphous ceramics, the specific process includes:

[0047] Step 1, Al 2 o 3 -Gd 2 o 3 -ZrO 2 Preparation of ternary system eutectic component powders. Select Al with a purity of 99.99% 2 o 3 Powder, Gd 2 o 3 Powder and ZrO 2 powder. According to Al 2 o 3 -Gd 2 o 3 -ZrO 2 Al 2 o 3 -Gd 2 o 3 -ZrO 2 Mix powder. Weigh 100g of the mixed powder obtained, and add 20ml of polyvinyl alcohol solution and 80ml of absolute ethanol to the weighed mixed powder, and use a ball mill to fully mix; the speed of the ball mill is 600r / min, and the ball milling time is 6h. Put the mixed powder into a drying ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com