Soft alloy layer forming apparatus and soft alloy layer forming method

A technology of soft alloy and base metal, which is applied in the field of soft alloy layer formation device and soft alloy layer formation, and can solve problems such as the difficulty in predicting the adhesion strength between the base metal and the bearing metal layer, increased production costs, and dispersion of adhesion strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

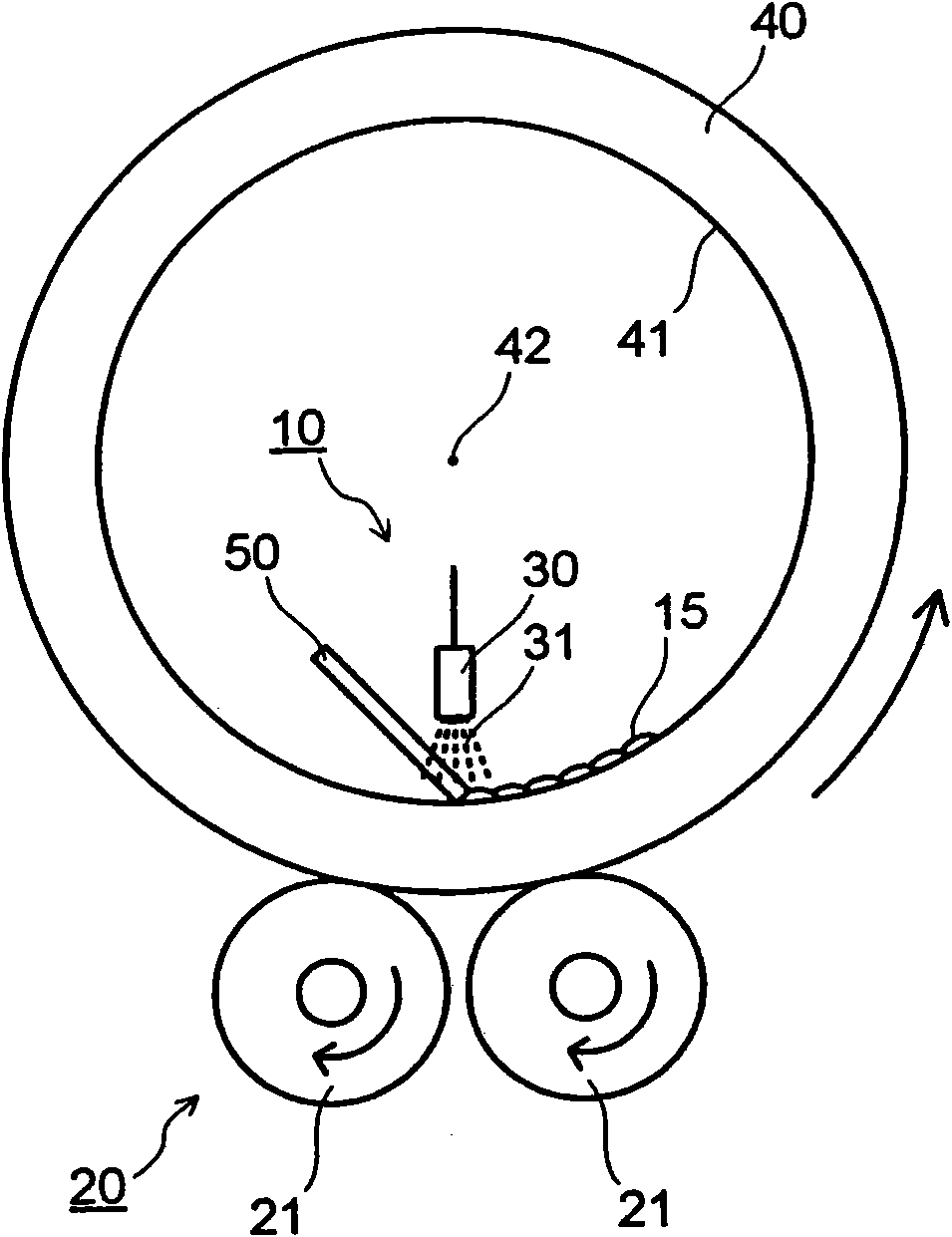

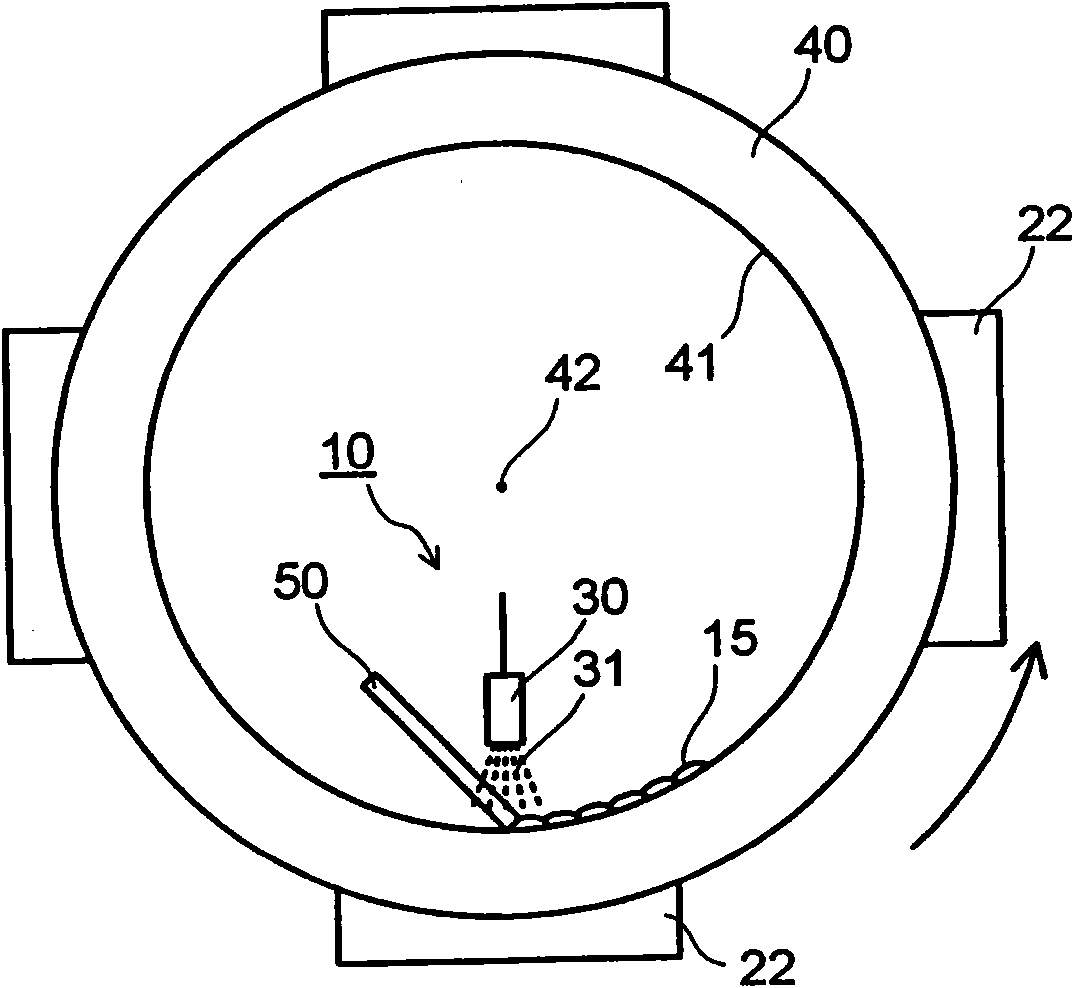

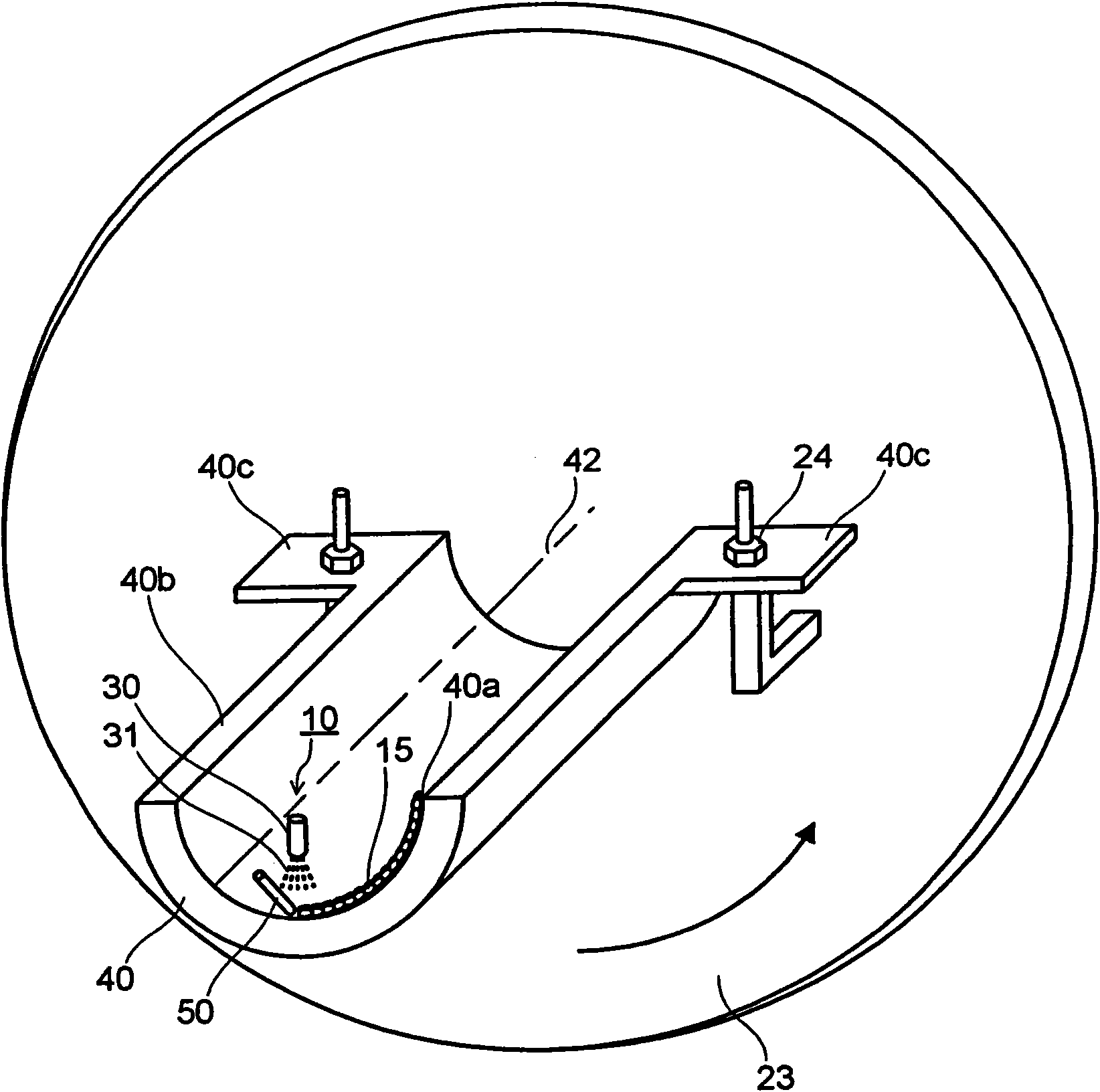

[0066] figure 1 The soft alloy forming apparatus 10 of the first embodiment of the present invention is schematically illustrated. Figure 2A and Figure 2B A soft alloy forming device 10 is schematically illustrated with a base metal support member 20 in another configuration. image 3A cross section of a base metal on which a soft alloy layer 15 is formed by the soft alloy layer forming apparatus 10 according to the first embodiment of the present invention is schematically shown. Figure 4 A cross-section of the interface between the base metal 40 and the soft alloy layer 15 is schematically illustrated.

[0067] The soft alloy layer forming device 10 is a device for forming a soft alloy layer 15 made of a soft alloy on the inner peripheral surface 41 of a base metal 40 made of an arc surface by a surfacing process, and the soft alloy layer slidably contacts with the rotor, For example turbine rotor contact. like figure 1 As shown in , the soft alloy layer forming ap...

no. 2 approach

[0087] Figure 5 A soft alloy layer forming apparatus 10 according to the second embodiment of the present invention is schematically illustrated. The soft alloy layer forming apparatus 10 of the second embodiment of the present invention provides the soft alloy forming apparatus 10 of the first embodiment of the present invention with a cooling gas injection unit 60 for injecting cooling gas to the soft alloy layer 15 and a cooling gas injection unit 60 for cooling the base metal. The base metal cooling unit 70 on the outer peripheral surface of 40 is constructed. Note that since the same components as those in the soft alloy layer forming apparatus of the first embodiment are assigned the same reference numerals, repeated descriptions are omitted or simplified.

[0088] like Figure 5 As shown in , the soft alloy layer forming apparatus 10 includes a base metal supporting member 20 , an arc generating unit 30 , a cooling gas injection unit 60 and a base metal cooling unit ...

Embodiment 1

[0103] In Example 1, a base metal 40 made of structural steel partially simulating a journal bearing having an inner diameter of 381 mm, an outer diameter of 481 mm and a center angle of 85° was prepared. Note that the method of forming the soft alloy layer is the same as that described in the first embodiment, so reference figure 1 Give the instructions below.

[0104] The base metal 40 is placed on the base metal supporting member 20, and the base metal is rotated while overlaying is completed from one end to the other in the direction of the rotation axis. Subsequently, the arc generating unit 30 is oscillated with an amplitude of 7 mm and a frequency of 3 Hz in the direction of the axis of rotation, where the axis of rotation is the base metal, and then a predetermined voltage is applied between the arc generating unit 30 and the base metal 40 to generate an arc 31 The central axis 42 of the inner periphery of the metal 40 . In addition, the welding current at this time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com