A laser additive and heat treatment composite process for preparing high-strength and tough aluminum-silicon alloys or their composite materials

A composite material and laser additive technology, which is applied in the field of metal materials, can solve the problems of unfavorable fine-grained structure and high aging temperature, and achieve good comprehensive mechanical properties, increased strength and hardness, and increased production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

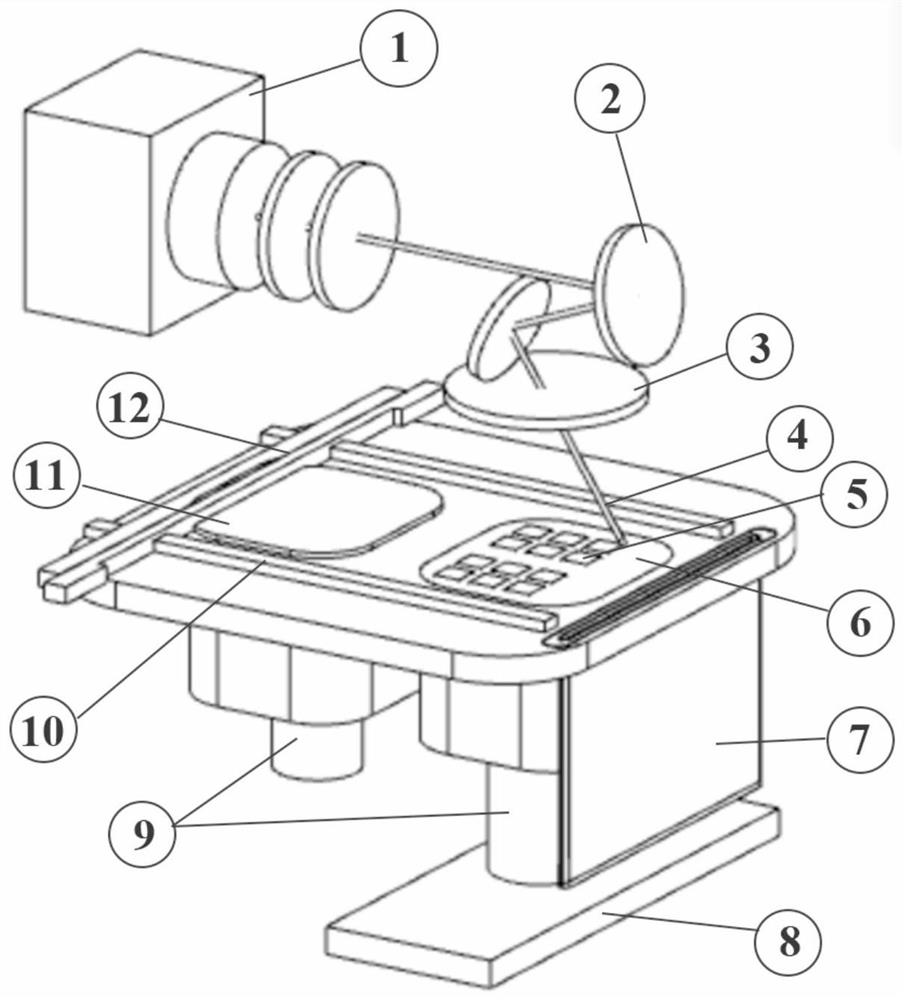

[0028] This embodiment is a composite process of laser material addition and heat treatment for preparing high-strength and tough aluminum-silicon alloys or their composite materials, and the device used in this process includes a laser selective melting printer. where the printer structure is as figure 1As shown, the laser printer is provided with a cooling system, a vacuum system and an inert gas protection device. The laser printer is provided with a powder spreading bed 6 and a recovery box 7. Before printing, the scraper 12 needs to be moved to the middle of the powder spreading bed 6. By adjusting Nuts at both ends of the scraper are used to adjust the distance between the scraper and the powder spreading bed 6, and then the AlSi10Mg powder is paved on the upper surface of the powder cylinder, and the powder of the powder bed is scraped out from the powder cylinder 11 by the scraper 12. The first layer of printing starts when the metal powder is laid flat on the powder b...

Embodiment 2

[0036] The structure of the preparation process device for synchronously improving the strength and plasticity of the AlSi10Mg material in this embodiment is the same as that in Embodiment 1.

[0037] The printing process of the metal block is the same as that in Embodiment 1, the difference is that the laser power is reduced to 245W to carry out the printing experiment of the metal block. The specific method is as follows:

[0038] The experimental environment is the same as in Example 1. Before printing, the scraper must be moved to the middle of the powder bed, and the distance between the scraper and the powder bed can be adjusted by adjusting the nuts at both ends of the scraper. After returning the metal powder in the powder cylinder, start the first layer of printing. The printing parameters are: laser power 245W, scanning speed 1.6m / s, layer thickness 30μm scanning distance 0.124mm, scanning method is strip strategy, layer to layer Rotate 67 degrees between them. Afte...

Embodiment 3

[0043] The structure of the preparation process device for synchronously improving the strength and plasticity of the AlSi10Mg material in this embodiment is the same as that in Embodiment 1.

[0044] The printing process of the metal block is the same as that in Embodiment 1, the difference is that the laser power is increased to 300W to carry out the printing experiment of the metal block. The specific method is as follows:

[0045] The experimental environment is the same as in Example 1. Before printing, the scraper must be moved to the middle of the powder bed, and the distance between the scraper and the powder bed can be adjusted by adjusting the nuts at both ends of the scraper. After returning the metal powder in the powder cylinder, start the first layer of printing. The printing parameters are: laser power 300W, scanning speed 1.6m / s, layer thickness 30μm scanning distance 0.124mm, scanning method is strip strategy, layer to layer Rotate 67 degrees between them. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com