Method for carrying out electroslag remelting by using single-inlet multi-outlet type water-cooling crystallizer electroslag remelting device

A technology of electroslag remelting and crystallizer, which is applied in the field of iron and steel metallurgy, can solve the problems of high performance, severe solidification segregation, and coarse grains that cannot meet the requirements of large-scale electroslag ingots, and achieve improved surface quality and internal quality and surface quality, the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

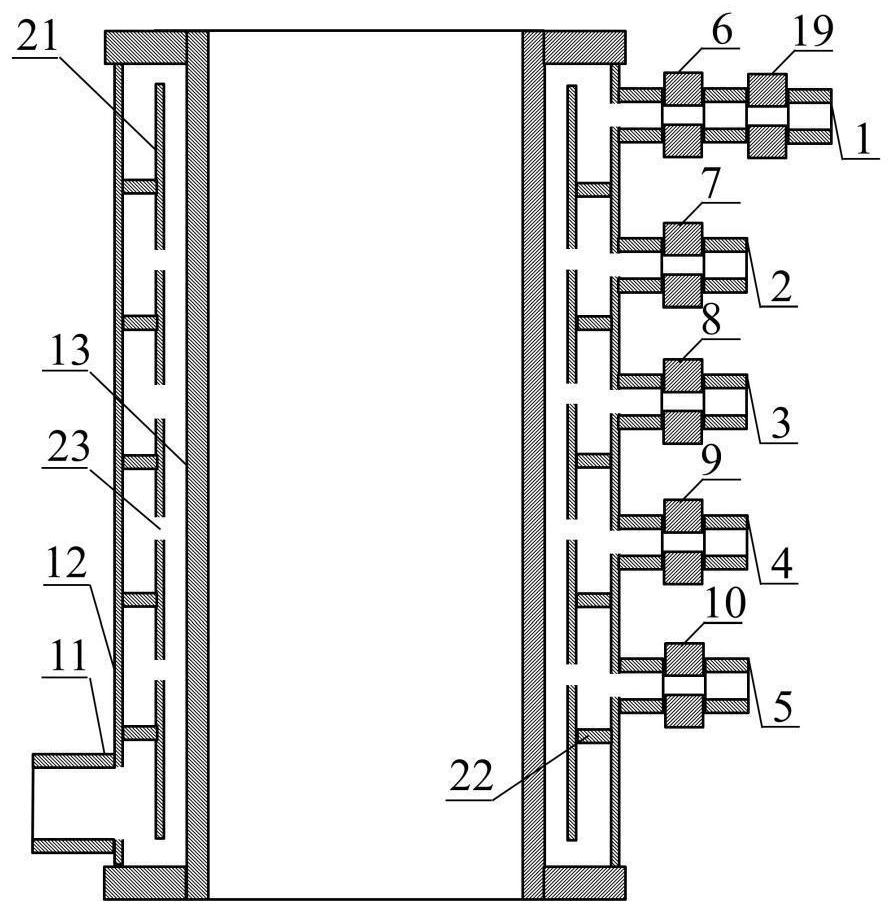

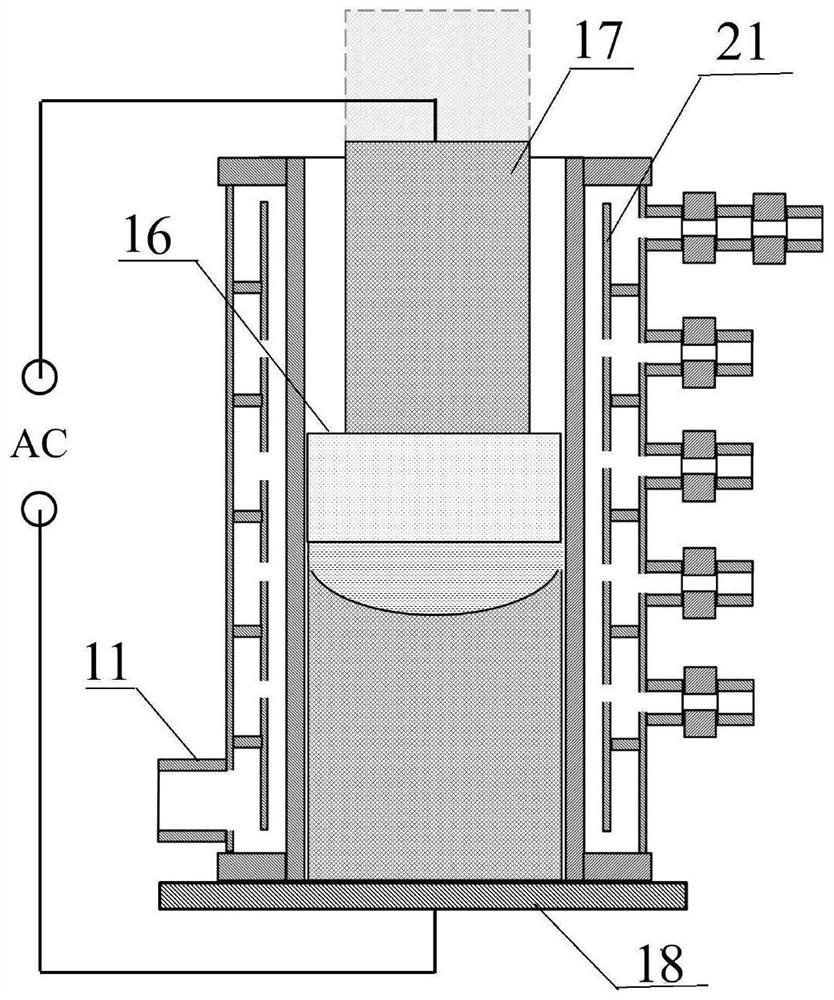

[0062] Such as figure 1 As shown, an electroslag remelting device for a single-inlet and multiple-outlet water-cooled crystallizer, including a water-cooled crystallizer and other conventional components, wherein the water-cooled crystallizer is a single-inlet and multiple-outlet water-cooled crystallizer according to the way of circulating water, with 1 #Water outlet 1, 2# Water outlet 2, 3# Water outlet 3, 4# Water outlet 4, 5# Water outlet 5, 1# Water outlet Electric control valve 6, 2# Water outlet Electric control valve 7, 3 The electric regulating valve 8 of the #water outlet, the electric regulating valve 9 of the 4# water outlet, the electric regulating valve 10 of the 5# water outlet, and the crystallizer water inlet 11 are all connected with the interlayer of the crystallizer. The water-cooled crystallizer copper A steel middle layer 21 is arranged between the steel inner layer 13 and the steel outer layer 12, and the steel middle layer 21 is installed on the inner w...

Embodiment 2

[0068] On the basis of Embodiment 1, the five water outlets are adjusted to nine water outlets vertically arranged up and down, and the rest remain unchanged. After the electroslag ingot is obtained, the as-cast structure of the electroslag ingot at the corresponding height between two adjacent water outlets is detected, and the secondary dendrite spacing inside the electroslag ingot and the grains of the structure are fine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com