Micro-filling film sealing machine provided with hydrophobic groove

A hydrophobic and micro-irrigation technology, applied in bottling machines, packaging, bottle filling, etc., can solve problems such as energy waste, and achieve the effect of short production line, small footprint and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

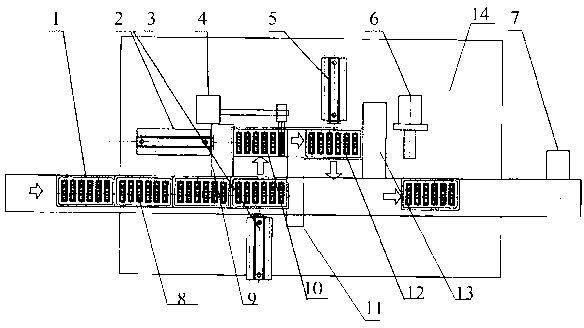

[0019] Such as figure 1 shown.

[0020] The micro-filling and sealing machine with hydrophobic grooves is mainly composed of an operating platform 14, a transmission system and a driving filling system arranged on the operating platform 14.

[0021] The transmission system includes a transmission chain belt 1 arranged on an operating platform 14, and a chain belt motor 7 connected to the transmission chain belt 1; a first membrane baffle plate 11 is arranged directly above the transmission chain belt 1, and the The axis of the first membrane baffle plate 11 is perpendicular to the axis of the transmission chain belt 1; the side wall of the transmission chain belt 1 is also provided with a second membrane body baffle plate 9 whose axes are all parallel to the axis of the first membrane body baffle plate 11 and the third membrane baffle 13, the second membrane baffle 9 and the third membrane baffle 13 are respectively located on both sides of the first membrane baffle 11.

[0...

Embodiment 2

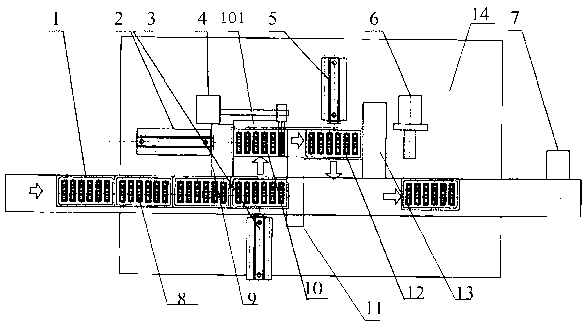

[0029] figure 2 As shown, the difference between the present embodiment and the first embodiment is: due to the quality problem of the bottle stopper during the filling operation in the filling cavity 10, the phenomenon of liquid leakage often occurs, so this embodiment is to prevent leakage. The liquid will pollute or corrode a large piece of the operating platform 14, for which a hydrophobic groove 101 is added, and there is a gap between the first membrane baffle 11 and the second membrane baffle 9, which constitutes the filling chamber 10 and the operating platform 14 is provided with hydrophobic grooves 101, and the hydrophobic grooves 101 are located on both sides of the filling chamber 10. In this way, in case of liquid leakage, the liquid will collect into the water-repellent groove 101 and be discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com