Forging forming device for coal mine scraper production

A forging molding and scraper technology, which is applied in forging/pressing/hammer devices, driving devices of forging presses, forging presses, etc., can solve the problems of workers who are easy to be injured and metal shavings flying out, so as to facilitate clamping and Effect of forging, improving practicality and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

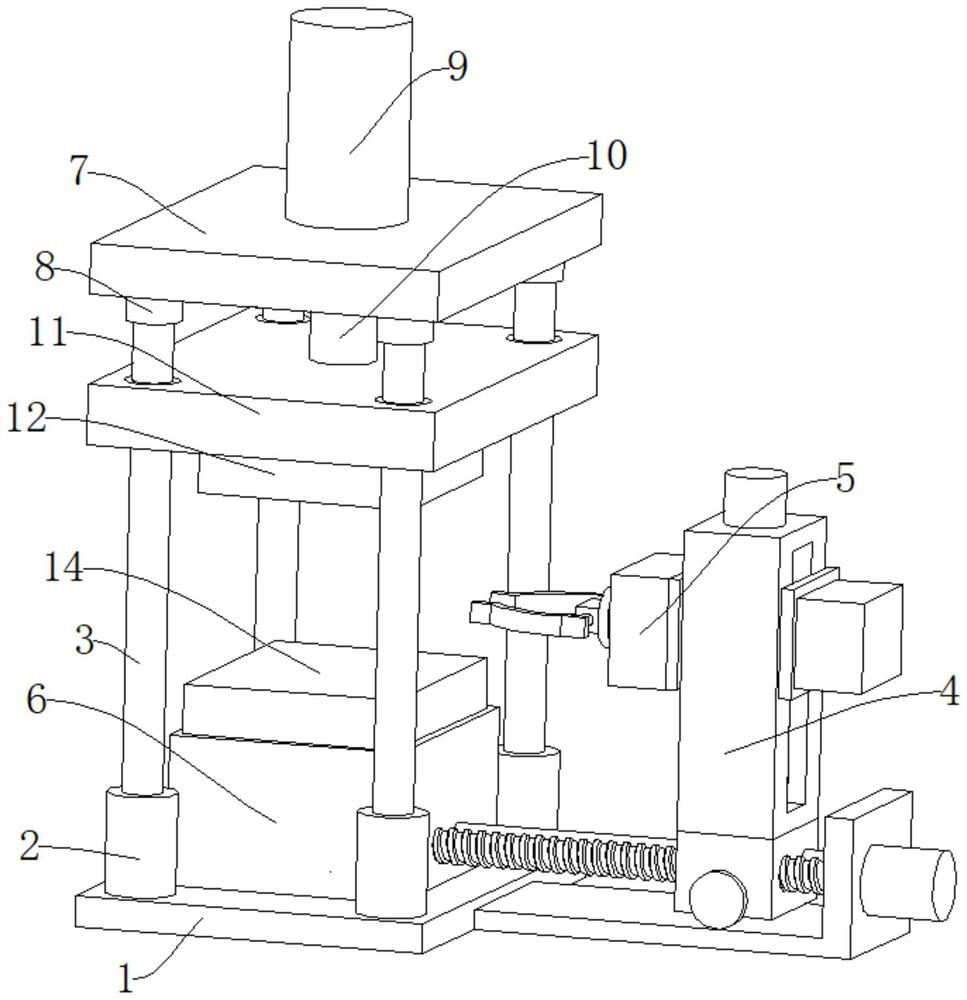

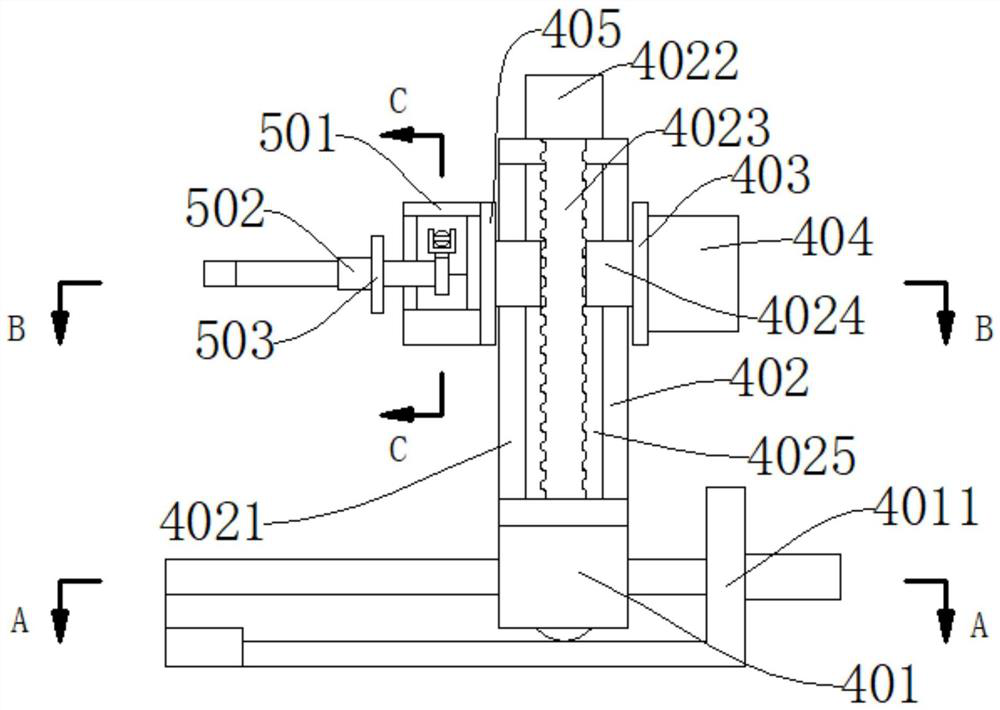

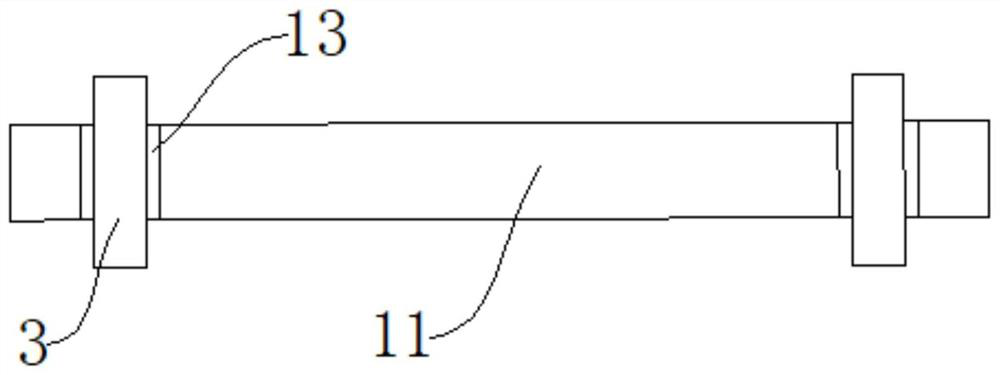

[0033] Such as Figure 1-6 As shown, the height adjustment assembly 402 includes a column 4021, a second servo motor 4022, a second screw 4023, and a second moving block 4024. The column 4021 is fixed on the top of the second moving block 4024 by screws, and an empty slot 4025 is provided in the column 4021. The top of the column 4021 is fixed with a second servo motor 4022 by screws, the input end of the second servo motor 4022 is electrically connected with the output end of the city bureau, the output end of the second servo motor 4022 is provided with a second screw 4023, and the second screw 4023 is arranged radially There is a second moving block 4024; the sleeve 2 is fixed on the bottom plate 1 by bolts, the bottom end of the guide post 3 is embedded in the sleeve 2, and the top end of the guide post 3 is embedded in the fixed sleeve 8; the one-way hydraulic cylinder 9 is fixed on the On the top plate 7, the moving plate 11 is fixed on the hydraulic rod 10 by screws, an...

Embodiment 2

[0036] Such as Figure 3-8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the second servo motor 4022 and the second screw 4023 are replaced with the first cylinder 4026 and the first push rod 4027. When in use, the forging is placed on the workbench 14 The position of the moving mechanism 4 is adjusted, and the first screw 4013 is driven by the first servo motor 4012 to rotate, so that the first moving block 4015, the moving wheel 4016 and the height adjustment assembly 402 move to the appropriate position with the slide bar 4014, and then the first cylinder 4026 drives the first push rod 4027, the second moving block 4024, the first connecting plate 403, the counterweight 404, the second connecting plate 405 and the clamping mechanism 5 to move to a suitable height, and then the two-way hydraulic cylinder 5021 drives the third pushing The rod 5022 and splint 5023 clamp the forged piece, and the first servo motor 4012 drives the first screw 4013 to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com