Carriage device for dyeing cloth basket

A technology for handling equipment and cloth, which is applied in the field of handling equipment for printing and dyeing cloth baskets, which can solve the problems of high labor intensity, heavy plastic baskets, inconvenience, etc., and achieve the effect of reducing labor intensity and convenient and fast transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

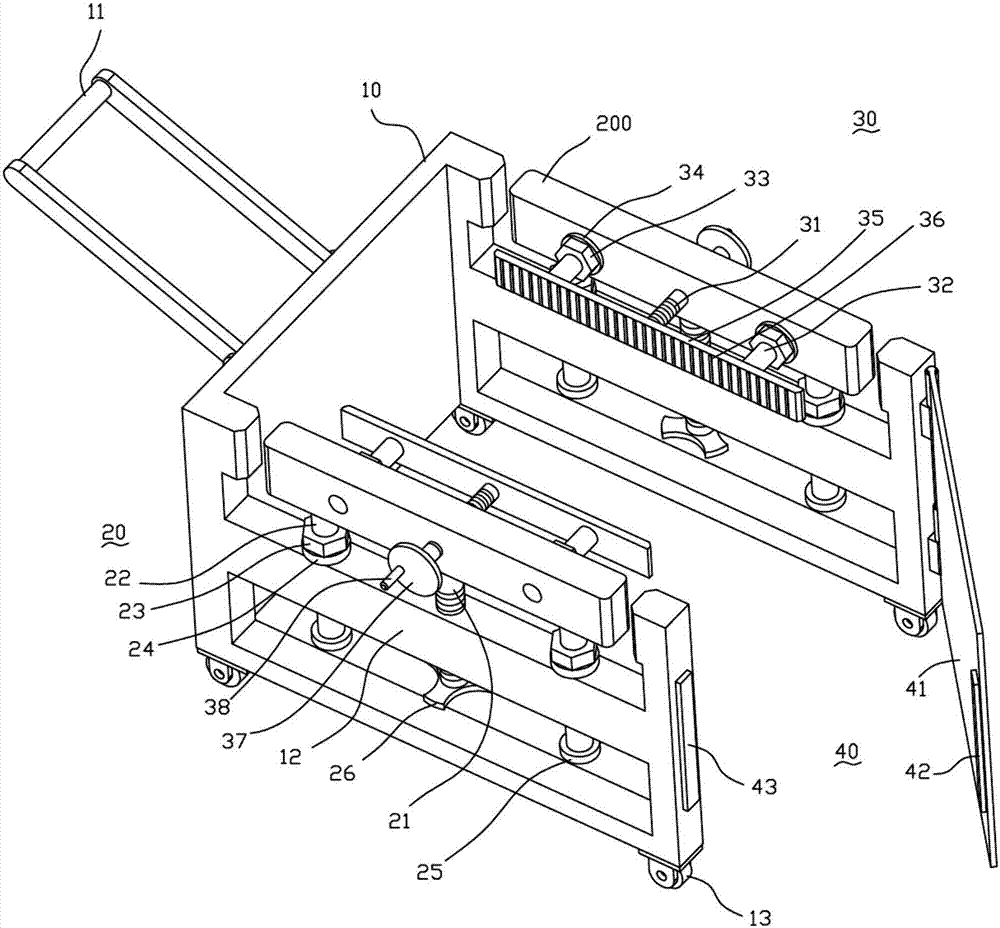

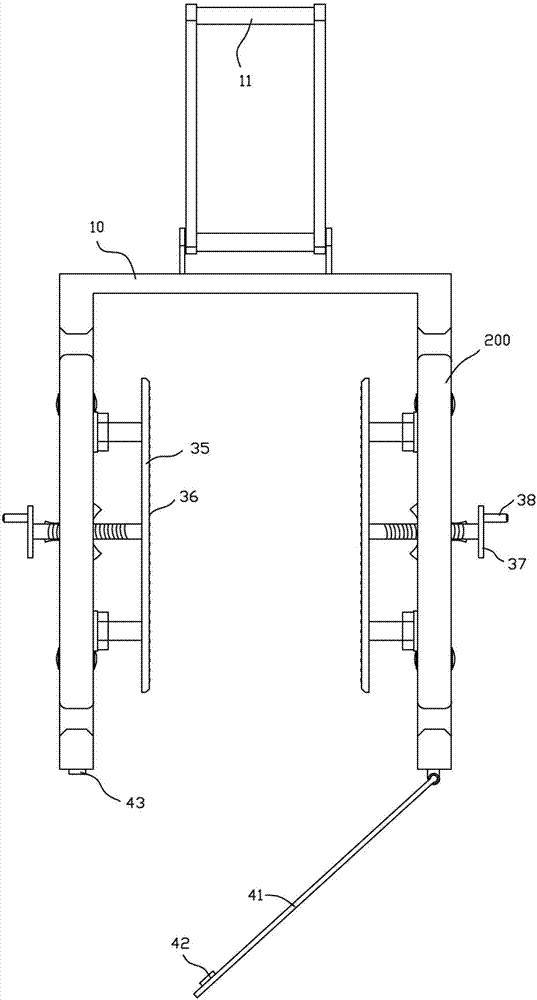

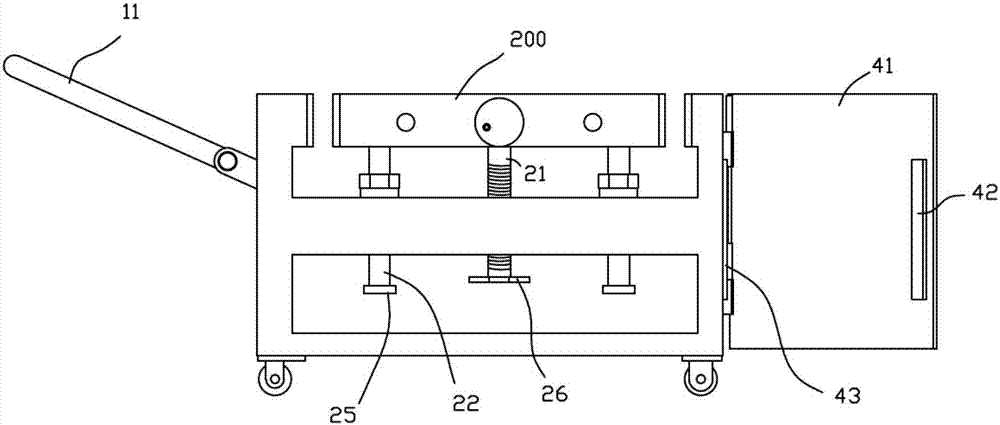

[0024] Such as Figure 1 to Figure 3 As shown, a kind of handling equipment for printing and dyeing cloth baskets includes a frame body 10, the bottom of the frame body 10 is provided with rollers 13, the number of the rollers 13 is four, and the front part of the frame body 10 is provided with handrails 11;

[0025] A support bar 12 is arranged among the two side parts of the frame body 10, and a height adjustment assembly 20 is arranged above the support bar 12, and the height adjustment assembly 20 includes a movable block 200, and the movable block 200 The vertical height direction can be adjusted; the side of the movable block 200 is provided with a horizontal clamping assembly 30, and the horizontal clamping assembly 30 includes a clamping plate 35, and the clamping plate 35 can move horizontally; the frame body 10 A baffle assembly 40 is also provided at the tail, and the baffle assembly 40 includes a baffle 41 , and the baffle 41 is hinged to the frame body 10 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com