Cleaning process and cleaning device for one or more parts of an application system

A cleaning device and cleaning technology, applied in the direction of cleaning methods using liquids, cleaning methods using gas flow, cleaning methods and appliances, etc., can solve problems such as high medium consumption, achieve the effect of reducing medium consumption and improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

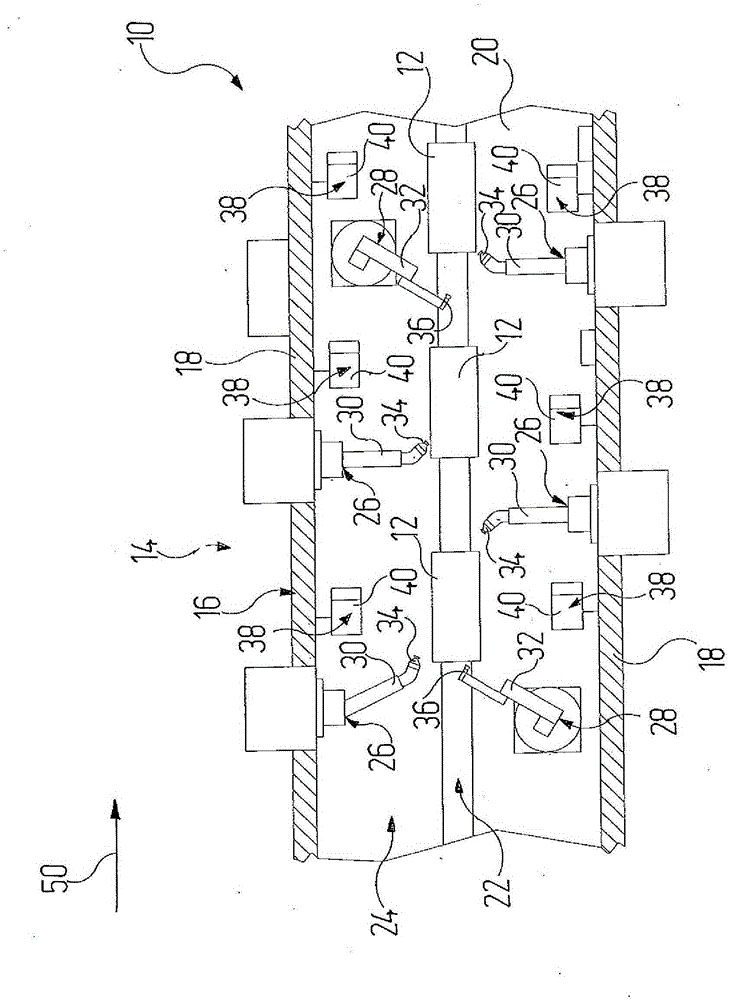

[0044] figure 1 A detail of a painting plant, indicated generally at 10 , is shown as an example of a plant for coating objects. In the painting installation 10 the object 12 is provided with a coating in the form of paint. exist figure 1 The medium object 12 is shown schematically as a rectangle. The object 12 to be coated can be, for example, a vehicle body, a body part, a machine part or a vehicle part such as a bumper or the like. Examples of devices for coating objects are, inter alia, painting devices, devices for applying anti-corrosion and / or insulating materials or devices for powder coating.

[0045] figure 1 A horizontal section through a section 14 of the paint booth 16 is shown below a hatch cover (not shown). In the example shown, the paint booth 16 has side walls 18 extending parallel to each other, which can be figure 1 In the region not shown again in , it is closed by an end face, wherein the end face has a door or gate for the object 12 in a known mann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com