Reed/crop straw harvesting bundler

A technology for crop straws and balers, which is applied in the direction of balers, harvesters, agricultural machinery and implements, etc., can solve problems such as waste and air pollution, and achieve the effects of facilitating transportation, improving production efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

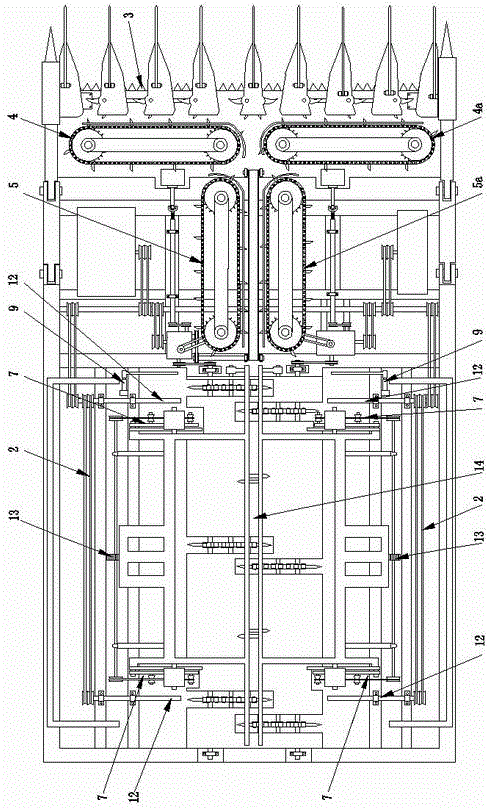

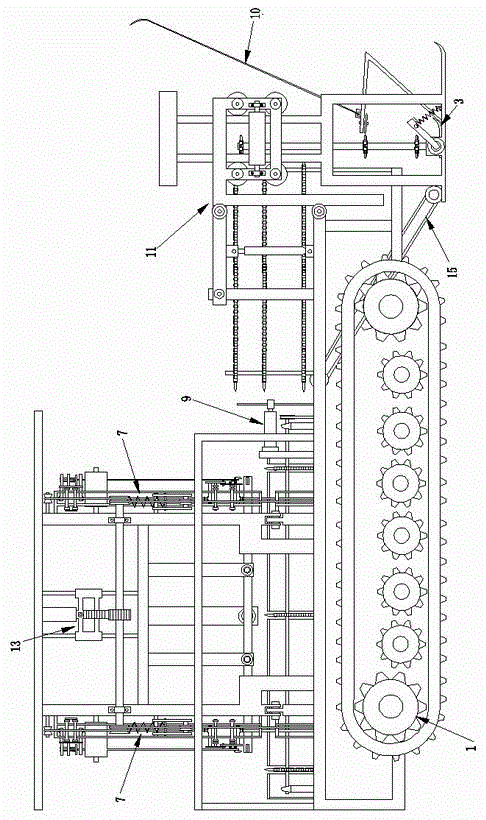

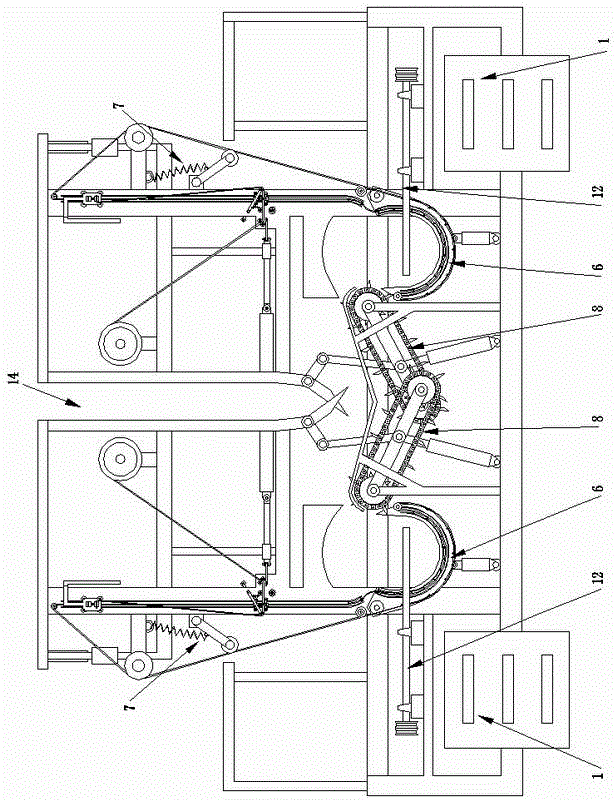

[0021] figure 1 , 2 , 3 shows a structural diagram of the main mechanism of a reed / crop straw harvesting and bundling machine. In the figure, the reed / crop straw harvesting and bundling machine includes a walking mechanism 1, a belt transmission mechanism 2, a cutter mechanism 3, a clockwise first horizontal feeding mechanism 4, a counterclockwise second horizontal feeding mechanism 4a, a clockwise The first vertical feeding mechanism 5 that rotates clockwise, the second vertical feeding mechanism 5a that rotates counterclockwise, two distribution mechanisms 8, two feeder mechanisms 6, four rope feeding mechanisms 7, two rope feeding gear mechanisms 13, Two alignment mechanisms 9, two transmission mechanisms 12 and a lifting mechanism 11. The first horizontal feeding mechanism 4, the second horizontal feeding mechanism 4a, the first vertical feeding mechanism 5, the second vertical feeding mechanism 5a, two distributing mechanisms 8, two beam feeding mechanisms 6, four rope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com