Surgical milling cutter

A milling cutter and milling technology, applied in surgery, medical science, diagnosis, etc., can solve problems such as false sense of security, achieve the effect of preventing unexpected injuries and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

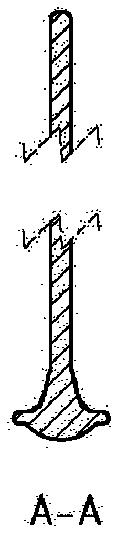

[0229] All embodiments have a rotationally symmetrical construction with respect to the center line of the milling cutter.

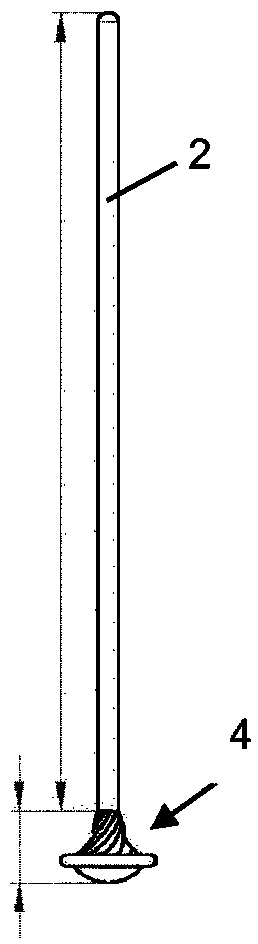

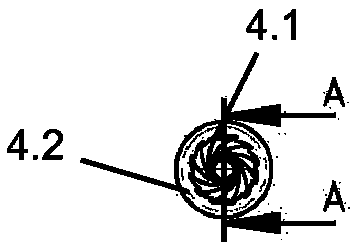

[0230] Correspondingly, figure 1 The milling cutter shown in mainly comprises a shaft part 2 with a top proximal end for being connected in a non-rotatable manner to a known driving device and a complex milling head 4 at the front distal end, the milling head having complex geometry.

[0231] The milling head 4 comprises a proximally oriented or proximally operated sharp milling surface 4.1 (here with a tooth structure), which widens from the outer peripheral surface of the shaft part 2 towards the distal end to a maximum circumference, wherein a protective ring 4.2 Surrounding the maximum perimeter in a ring configuration and projecting radially outwardly beyond the maximum perimeter. A distal protruding protective cap 4.3 is provided at the distal front end with a somewhat reduced radius, and the protective cap 4.3 is retracted or indented relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com