Automated shoe mold cutting machine

A cutting machine and shoe mold technology, which is applied to shoe-making machinery, footwear, apparel, etc., can solve the problems of low material replacement work efficiency and damage to the discharge plate, and achieve the effect of saving labor and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

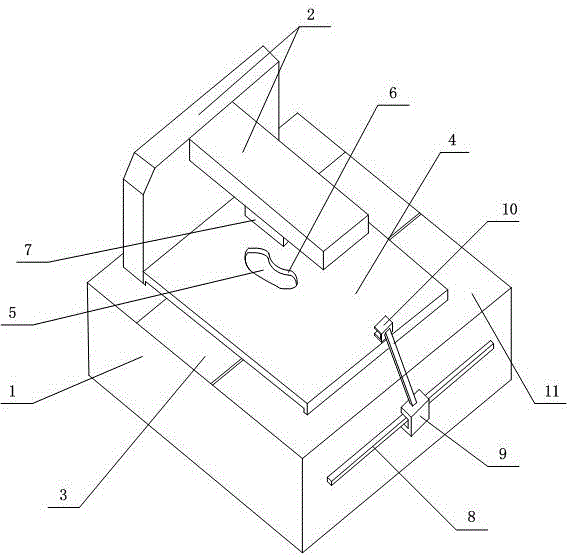

[0022] Such as figure 1 As shown, an automatic shoe mold cutting machine of the present invention includes a frame 1, a working platform 11, a molding mechanism 2 arranged on one side of the working platform, and a shoe template 4 arranged on the working platform, the shoe template A shoe mold hole 5 is arranged on the shoe mold hole, and a knife mold 6 having the same shape as the shoe mold hole is provided on the side wall of the shoe mold hole; The shape of the block is the same as that of the hole of the shoe mold; a conveyor belt 3 is provided between the working platform and the shoe template; a horizontal guide rail 8 arranged on the side of the frame is also included, and a slide for moving back and forth on the guide rail is provided on the guide rail. block 9; the slide block is connected with a slide bar, and the slide bar is provided with a collet 10, and the collet is positioned at the side of the shoe template; control device.

[0023] When the cutting machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com