Planetary reducer shell machining process and drilling mechanism

A planetary reducer and drilling mechanism technology, applied in the field of workpiece processing, can solve the problems of inconvenient recycling operation, increased labor intensity of workers, waste of resources, etc., and achieve the effects of convenient operation, high degree of automation, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

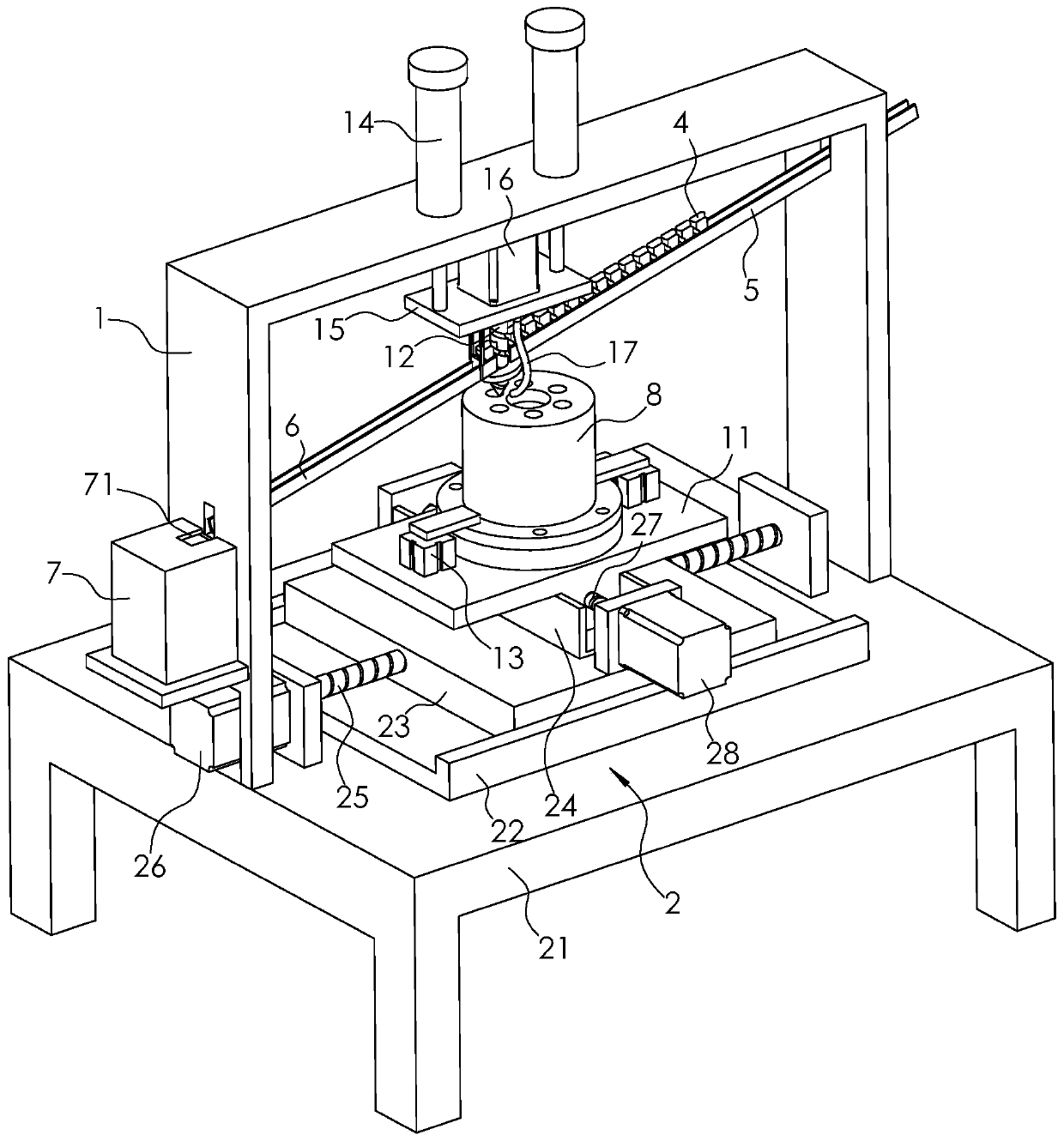

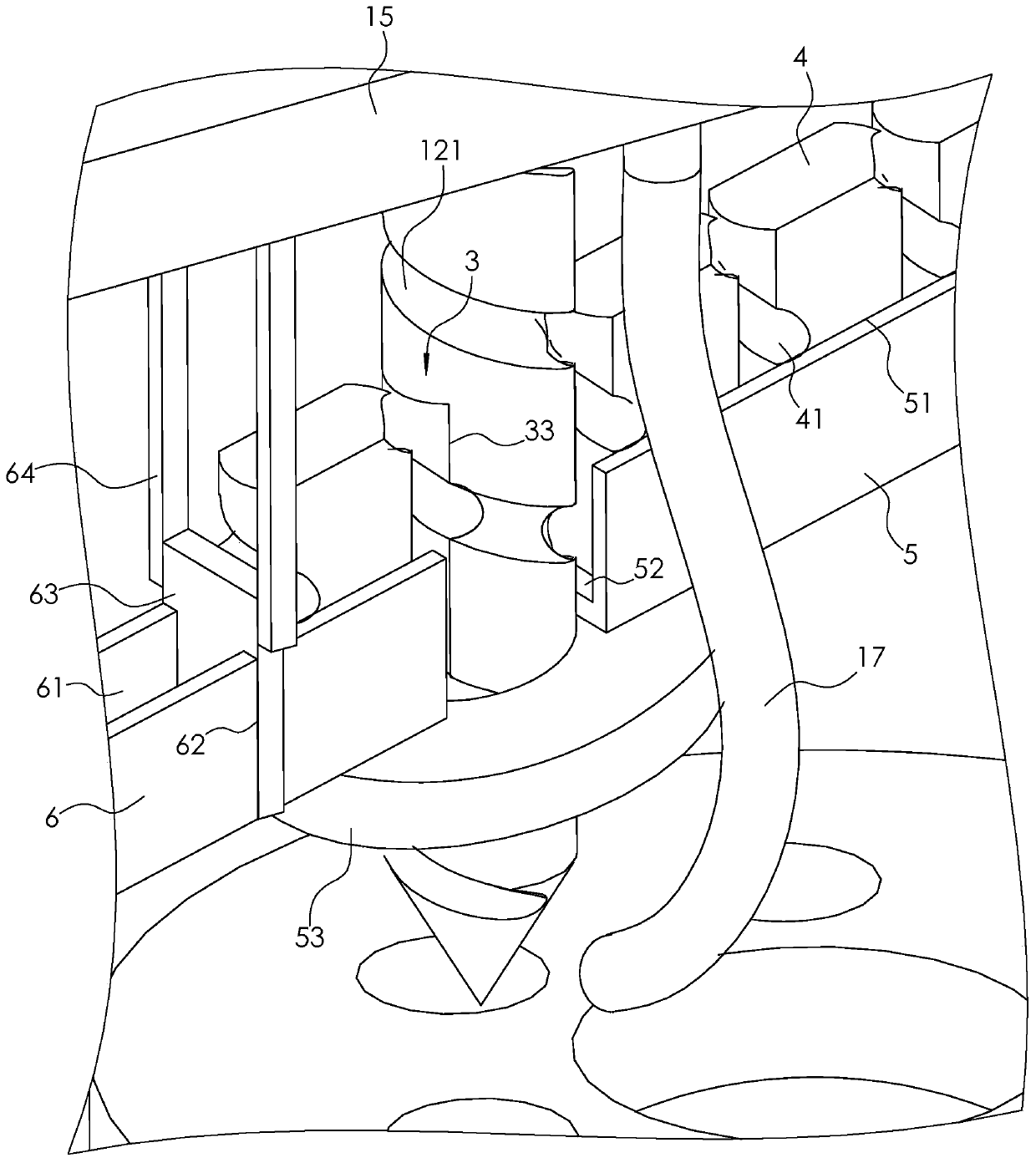

[0041] Embodiment one: if figure 2Shown, a kind of drilling mechanism comprises frame 1, and frame 1 is provided with workbench 11 and the drill bit 12 that is positioned at the top of workbench 11, and workbench 11 is provided with the fixture 13 that is used for clamping workpiece, and the workman can according to For different workpieces, corresponding fixtures 13 are selected to clamp the workpieces, so details will not be repeated here.

[0042] Such as figure 2 As shown, the frame 1 is also provided with a drive assembly 2, the drive assembly 2 includes a fixed plate 21 fixed on the frame 1, the fixed plate 21 is fixed with a first track 22 extending in the horizontal direction, the first track 22 is "U" shape setting; the first track 22 is slidingly embedded with a slide plate 23, the second track 24 is fixed on the slide plate 23, and the second slide track 6 is set in a "U" shape, and the extending direction of the second track 24 is in line with the first The ext...

Embodiment 2

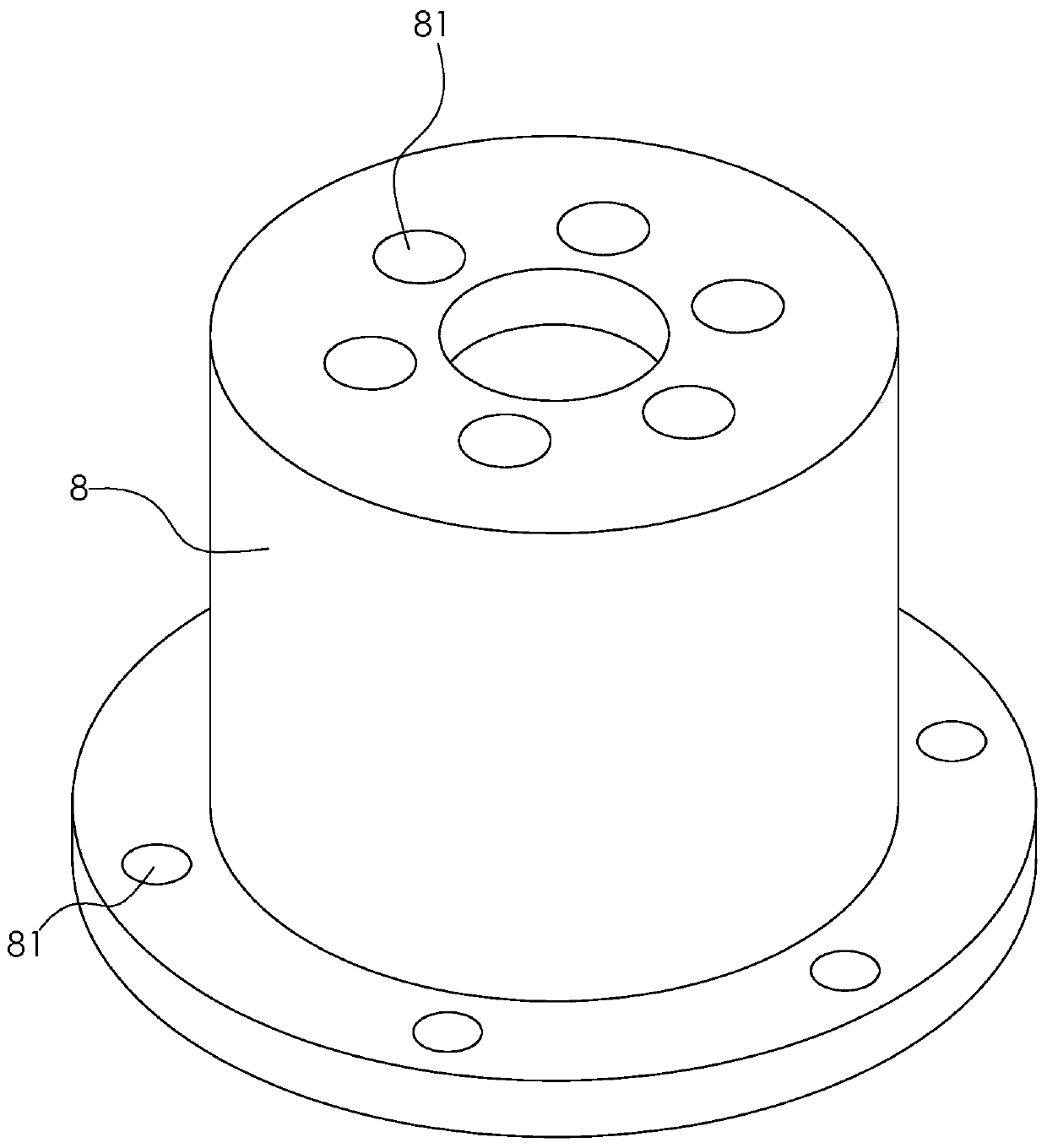

[0057] Embodiment 2: A processing technology for a planetary reducer housing 8, including the following steps:

[0058] A. Carry out rough grinding on the inner side of the planetary reducer housing 8 by a lathe;

[0059] B. Carry out rough grinding on the outer side of the planetary reducer housing 8 by a lathe;

[0060] C. Electrophoresis is performed on the planetary reducer housing 8 through the electrophoresis equipment. Since the electrophoresis equipment is a prior art, it will not be repeated here;

[0061] D. Carry out turning and fine grinding on the inner side of the planetary reducer housing 8 by a lathe;

[0062] E. Carry out turning and fine grinding on the outer side of the planetary reducer housing 8 by a lathe;

[0063] F, drill the top of the planetary reducer housing 8 through the drilling mechanism in Embodiment 1;

[0064] G. The bottom of the planetary reducer housing 8 is drilled through the drilling mechanism in Embodiment 1;

[0065] H. Use a tappi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com