Automatic fuelling device

A technology of automatic refueling and oil pressure, applied in the directions of engine components, engine lubrication, lubrication pumps, etc., can solve the problems of high cost, multi-function equipment, complex structure, etc., and achieve the effect of low cost, easy manufacturing and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

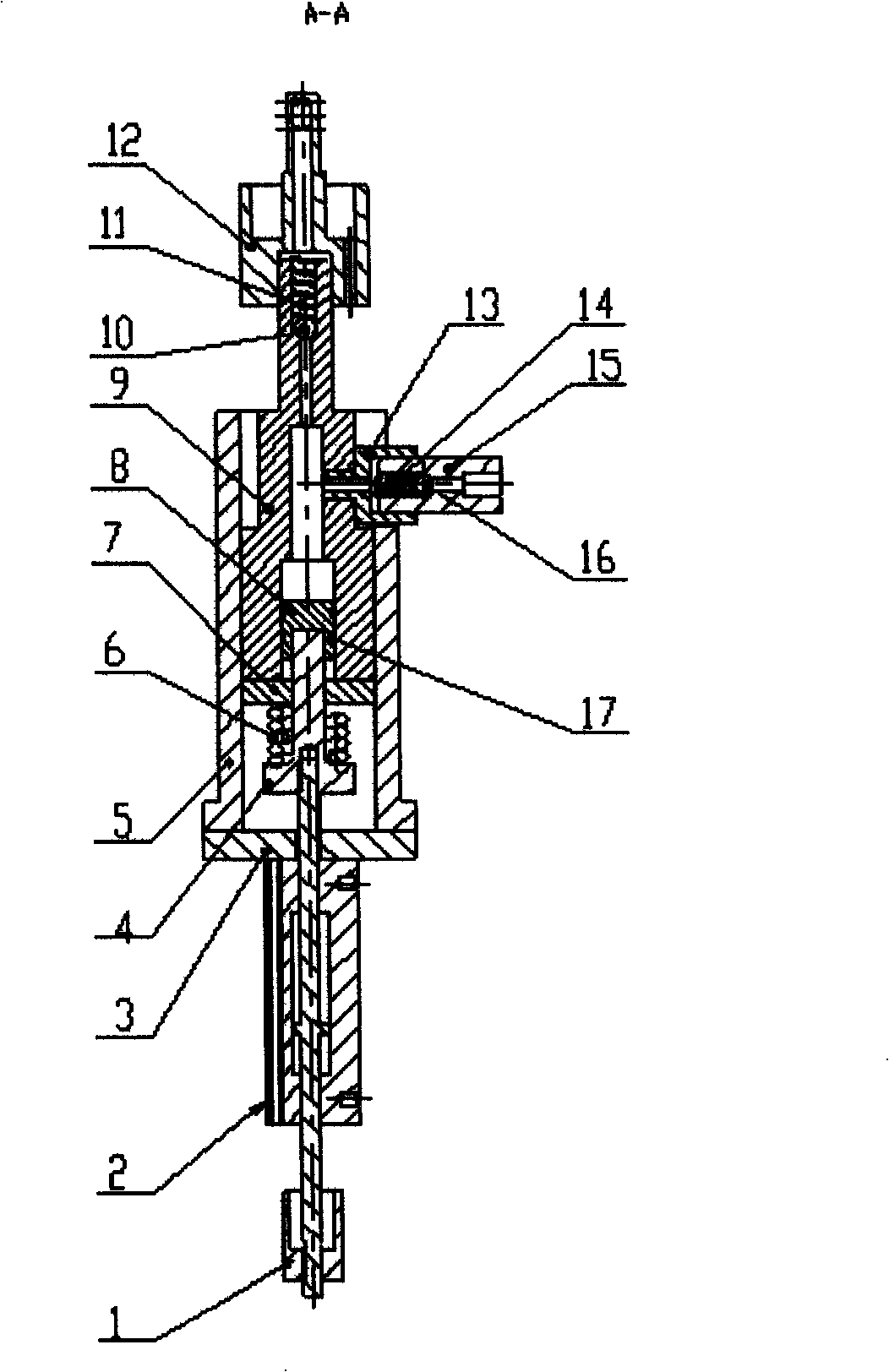

[0015] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

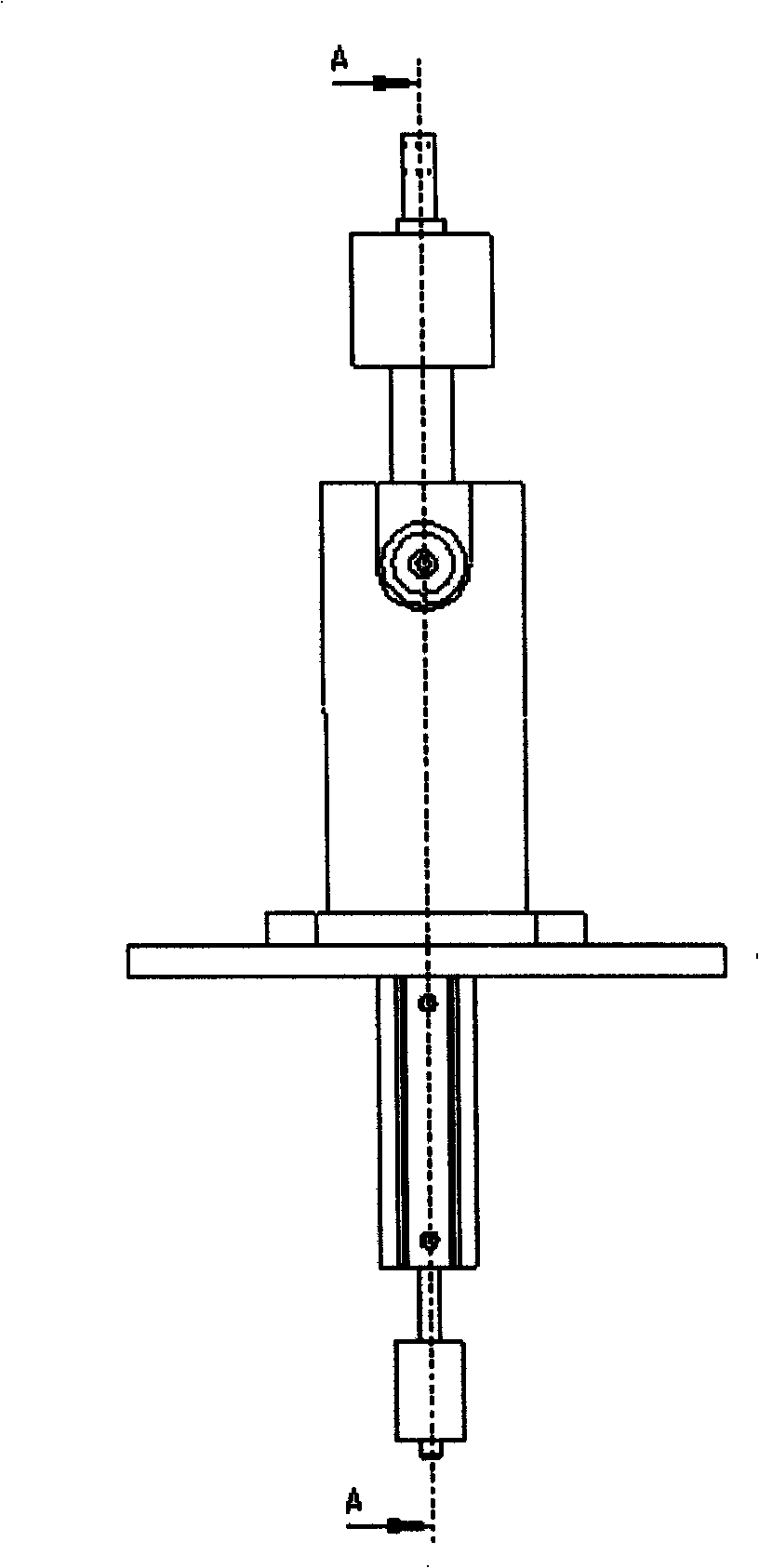

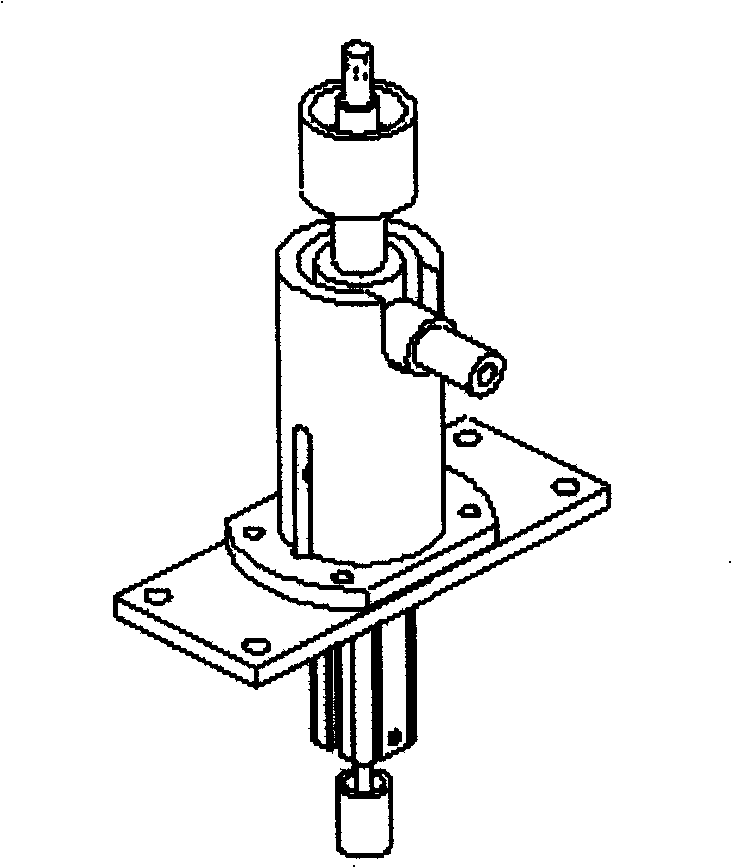

[0016] see figure 1 and figure 2 , the automatic refueling device includes an oil pressure cylinder 9 and an oil pressure piston 8 matched therewith, and a piston connecting rod 4 connected with the oil pressure piston 8 . It is characterized in that the oil outlet of the hydraulic cylinder 9 is connected to an oil outlet nozzle 12 through an oil outlet check valve, and the oil inlet is connected to the oil inlet pipe joint 15 through an oil inlet check valve; the outer end of the oil pressure piston 8 Connected to a matching piston rod of an actuating cylinder 2.

[0017] For further detailed structure see figure 2 , the adjusting screw sleeve 1 is fixed on the piston rod end of the cylinder 2 through threads; the cylinder 2 is fixedly connected with the mounting plate 3 through bolts; the piston connecting rod 4 is connected with the other piston ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com