Automatic frying machine

A frying machine, automatic technology, applied in the utensils for frying things in oil, oil/fat baking, household appliances, etc., can solve the problem of affecting business or frying operations, lack of automatic oil filling structure design, and heavy oil barrels And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

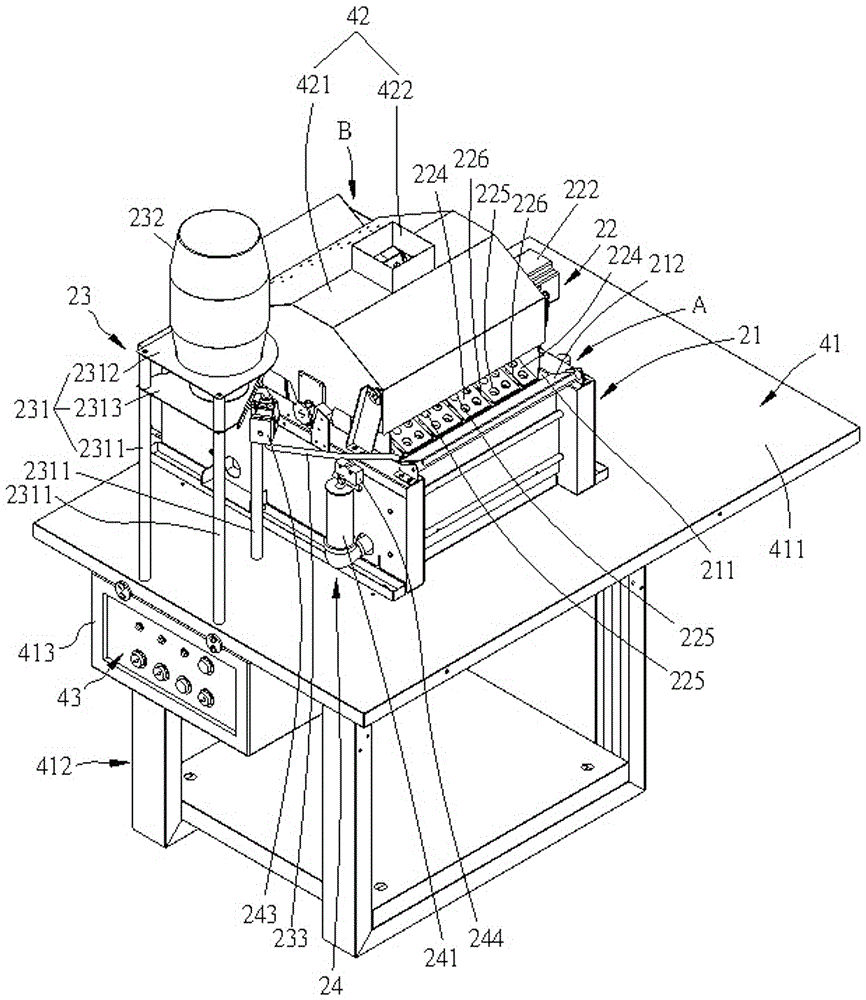

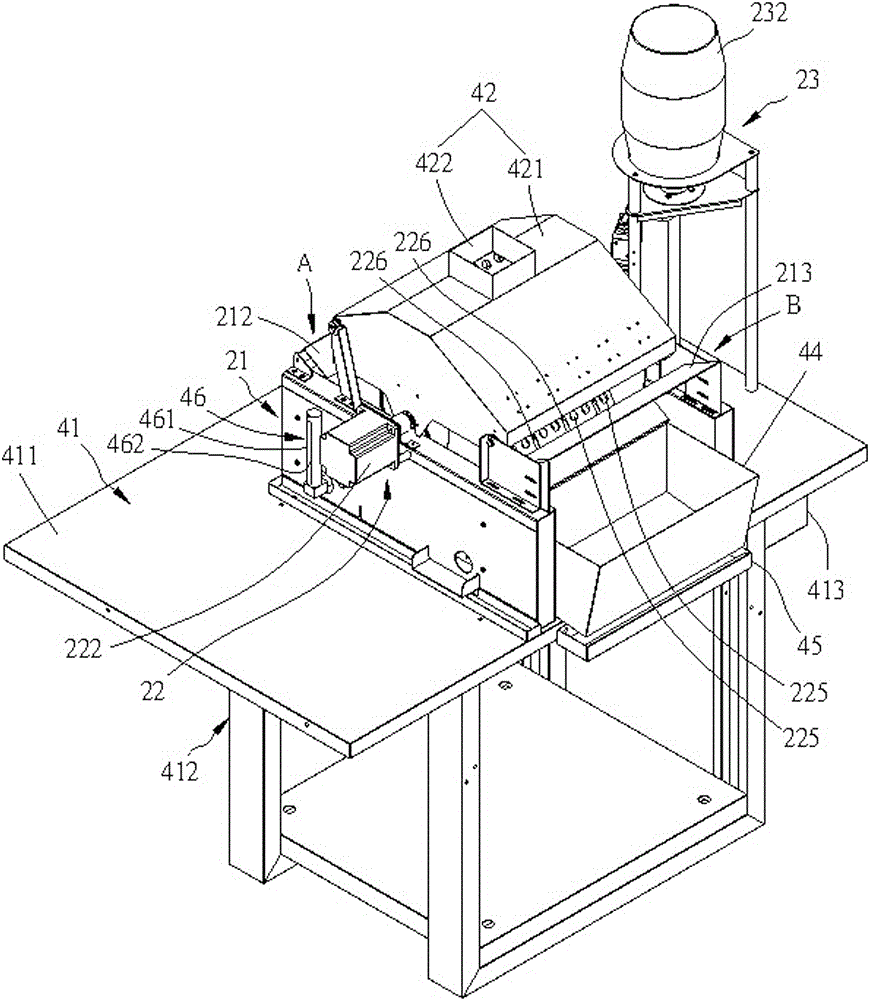

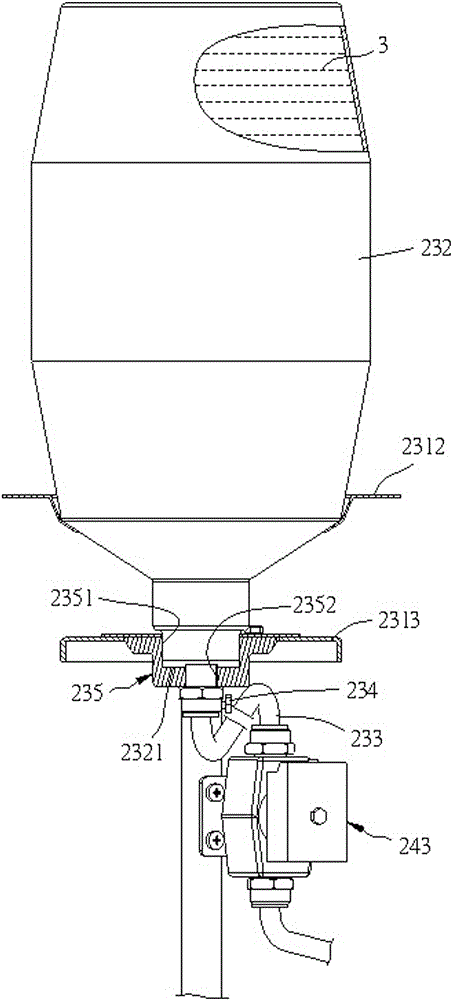

[0039] Examples such as figure 1 with figure 2 Shown, is an embodiment of the automatic fryer of the present invention, and this automatic fryer is used for making to-be-fried object 11 (see in Figure 11 ) deep-fried to form cooked fries 12 (see Figure 13 ). The automatic fryer includes a fryer box 21 , a toggle unit 22 , an oil supply unit 23 , and an automatic oil filling unit 24 .

[0040] Cooperate with reference Figure 9, the fryer box 21 defines a feed side A, and a discharge side B. The frying box 21 has an oil tank 211 , a feed plate 212 inclined on the feeding side A, and a discharge plate 213 inclined on the discharge side B. One end of the feeding plate 212 is inclined downward toward the oil holding groove 211 , and the food 11 to be fried can slide into the oil holding groove 211 from the feeding plate 212 , and one end of the discharging plate 213 is inclined upward toward the oil holding groove 211 .

[0041] The toggle unit 22 includes a runner 221 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com