Novel activated carbon desulfurization and denitration device

A desulfurization and denitrification, activated carbon technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of large pressure drop, large system pressure drop, thick carbon layer, etc., and achieve uniform exhaust gas flow rate and system pressure drop Small, sufficient adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0026] The structures not specifically described in detail in the present invention can be understood as conventional structures in the art.

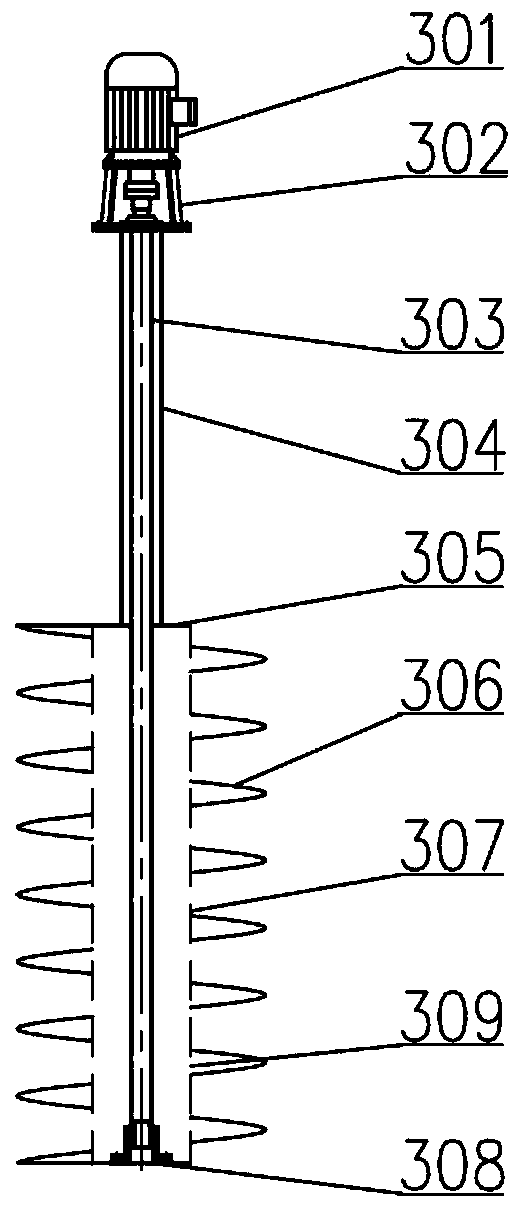

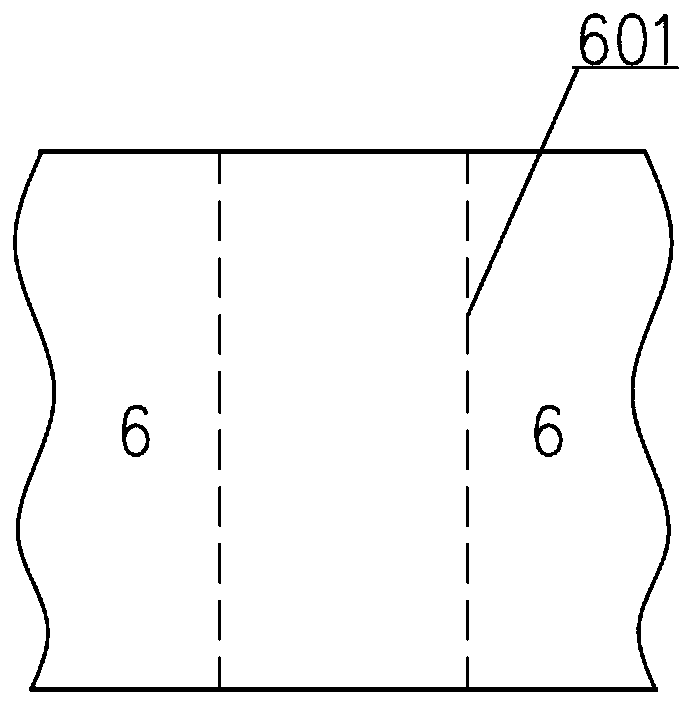

[0027] A new type of activated carbon desulfurization and denitrification device, such as figure 1 , figure 2 and image 3 As shown, the device includes an activated carbon silo 1, an activated carbon adsorption box 2, conical discharge bins 7, 8, 9, star discharge valves 10, 11, 12, a screw discharge device 3 and an ammonia injection reaction chamber, Activated carbon can be contained in the activated carbon silo, and the activated carbon silo, activated carbon adsorption box, conical unloading bin and star unloading valve are arranged in close connection from top to bottom, and the spiral unloading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com