Automatic oil injection device of electronic cigarette and mechanical dripping device capable of controlling dripping amount

A technology for automatic oil filling and electronic cigarettes, which is applied in the fields of tobacco, smoker's products, applications, etc., and can solve the problems of difficulty in controlling the amount of e-liquid added, complicated, and troublesome to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

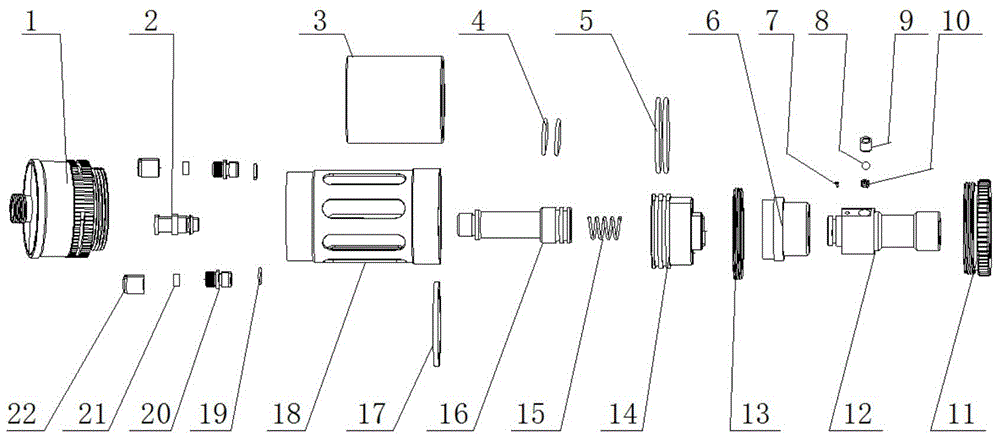

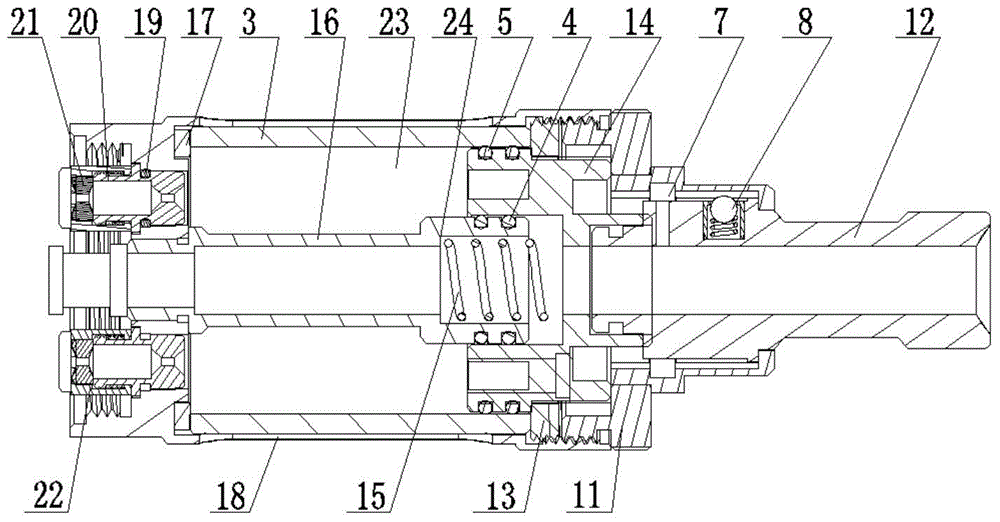

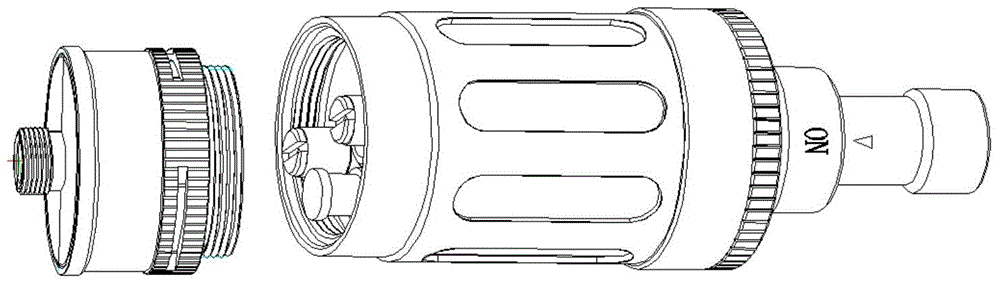

[0027] Such as figure 1 As shown in , the automatic refueling device of the electronic cigarette of the present invention is composed of a mouthpiece assembly, a cartridge assembly and an atomizer assembly 1 .

[0028] The mouthpiece assembly is composed of a mouthpiece body 12 , an adjustment seat 6 and an adjustment mechanism, wherein the adjustment mechanism is arranged between the adjustment seat 6 and the mouthpiece body 12 . The adjustment mechanism is composed of a positioning pin 7 arranged on an axial platform of the mouthpiece body 12 and an axial groove and an annular groove correspondingly arranged on the inner wall of the adjustment seat. The annular groove and the axial groove are in the shape of a "T" The structure is connected. The mouthpiece body 12 can rotate relative to the adjustment seat 6 , and when the positioning pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com