3D printer, control method of 3D printer and computer readable storage medium

A technology of 3D printer and control method, applied in the direction of 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problems of waste of consumables, printing failure, insufficient remaining material, etc., and achieve the effect of avoiding waste of consumables and printing failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

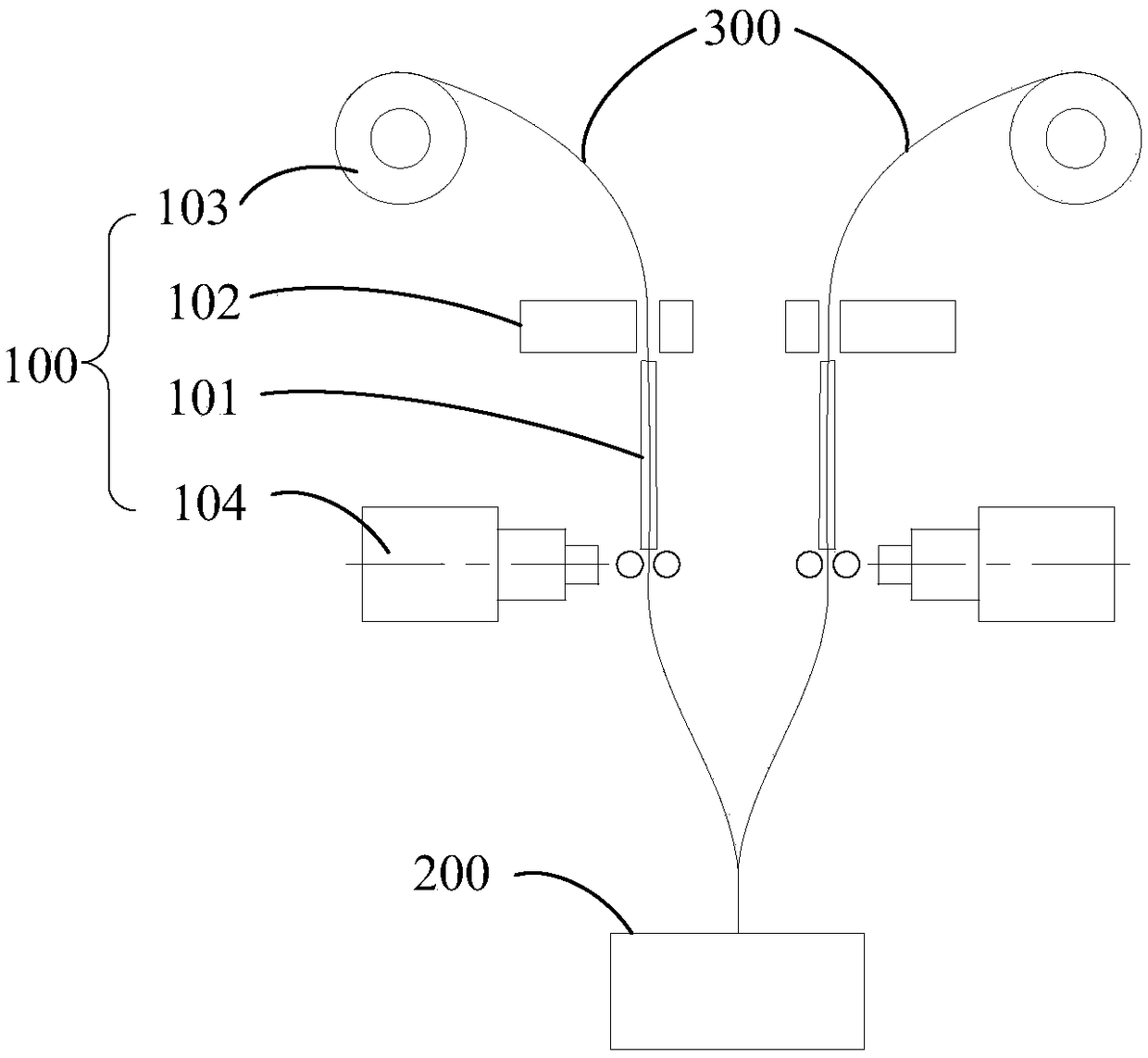

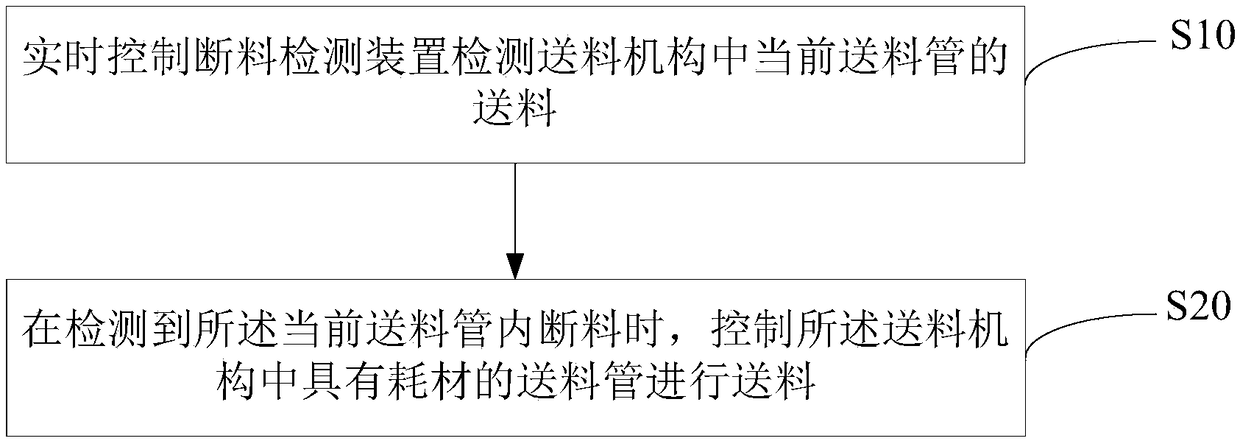

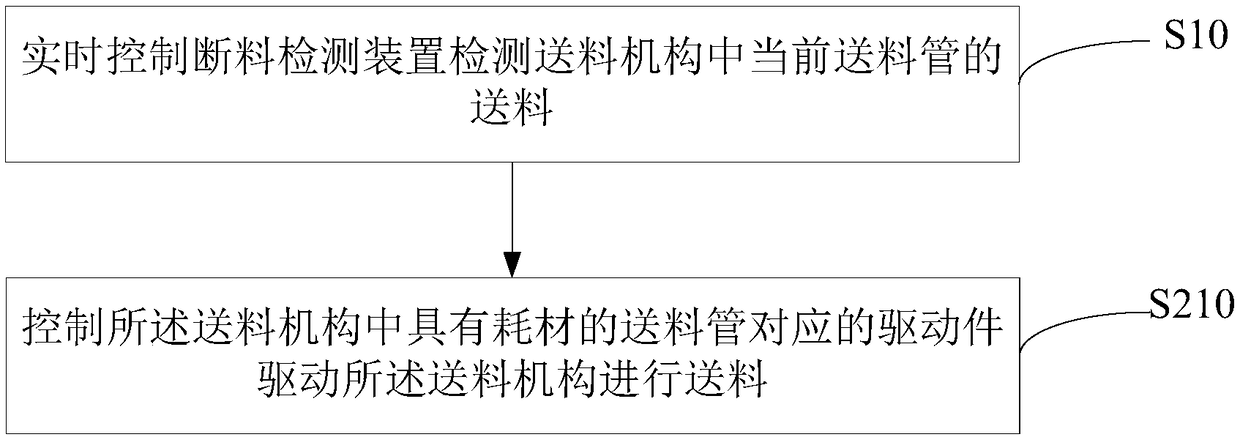

[0044] Based on the above-mentioned 3D printer, the present invention also provides a control method of a 3D printer, referring to figure 2 , the first embodiment of the control method of the 3D printer proposed by the present invention, the control method of the 3D printer includes the following steps:

[0045] Step S10, real-time control of the broken material detection device to detect the feeding of the current feeding pipe in the feeding mechanism;

[0046] This implementation control method can be run on the 3D printer, and can also be run on the control device of the 3D printer. The 3D printer is provided with multiple groups of feeding tubes, and each group of feeding tubes is provided with a material breaking detection device. The real-time control The material breaking detection device detects the feeding situation of the current feeding pipe in the feeding mechanism. For example, when the current feeding pipe is feeding, if there are consumables in the feeding pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com