Fixed abrasive polishing roll for Roll-to-Roll chemical mechanical polisher and preparation method for fixed abrasive polishing roll

A technology of bonded abrasives and chemical machinery, which is applied in the direction of grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of material removal rate decline, material removal rate inconsistency, plastic deformation, etc., and achieve uniform material removal rate , The material removal rate is consistent, and the effect of plastic deformation is not easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

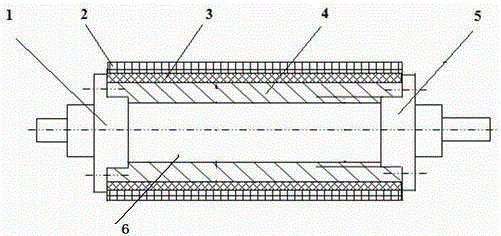

[0046] The basic structure of the present invention is:

[0047] Both sides of the fixed abrasive polishing roller are respectively provided with a polishing roller left end support mechanism 1 and a polishing roller right end support mechanism 5, and the outer side of the fixed abrasive polishing roller 6 is provided with a fixed abrasive polishing roller matrix layer 4, and the fixed abrasive polishing roller The outer side of the base layer is provided with an elastic layer 3 , and the outer side of the elastic layer is provided with a rigid layer 2 .

[0048] A preparation method for a Roll-to-Roll chemical mechanical polishing machine with a fixed abrasive polishing roller, comprising the following steps:

[0049] (1) Prepare a number of glassware and stirrers,

[0050] (2) Select according to the formula of the rigid layer: abrasives, photocurable resins, reactive diluents, photoinitiators, accelerators, surface property modifiers, auxiliary agents, fillers, and pigment...

Embodiment 2

[0074] Preparation method is the same as embodiment 1, and the material selection of concrete rigid layer and elastic layer is:

[0075] Rigid layer: Weigh 70g of white corundum abrasive with a particle size of 14μm, 150g of urethane acrylate (aliphatic) with a functionality of 4, 150g of urethane acrylate (aromatic) with a functionality of 4, and 120g of polystyrene with a functionality of 4. Ester acrylate, 360g pentaerythritol triacrylate, 40g 2-hydroxy-2-methyl-1-phenylacetone, 10g 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 5g dimethicone , 20g modified polysiloxane, 25g polyethylene wax, 30g 2,6-di-tert-butyl p-cresol, 18g talcum powder, 2g pigment yellow (PY129).

[0076] Elastic layer: Weigh 300g of urethane acrylate (aliphatic) with a functionality of 3, 200g of urethane acrylate (aromatic) with a functionality of 3, 200g of 1,6-hexanediol diacrylate, 1-hydroxy ring 50 g of hexyl phenyl ketone, 5 g of tributyl phosphate, 40 g of p-hydroxyanisole, 5 g of walnut sh...

Embodiment 3

[0078] Preparation method is the same as embodiment 1, and the material selection of concrete rigid layer and elastic layer is:

[0079] Rigid layer: Weigh 60g of white corundum abrasive with a particle size of 7μm, 150g of polyurethane acrylate (aliphatic) with a functionality of 4, 150g of polyurethane acrylate with a functionality of 4 (aromatic), and 120g of modified epoxy acrylate , 200g pentaerythritol triacrylate, 170g pentaerythritol tetraacrylate, 40g 2-hydroxy-2-methyl-1-phenylacetone, 10g2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 10g poly(diphenyl) Methyl silicone oil, 20g modified polysiloxane, 15g aluminum stearate, 5g tung oil, 20g 2,6-di-tert-butyl-p-cresol, 18g talc, 10g kaolin, 2g phthalocyanine blue (PB15).

[0080] Elastic layer: Weigh 100g of polyester acrylate with a functionality of 3, 300g of polyurethane acrylate (aliphatic) with a functionality of 3, 400g of diethylene glycol diacrylate, and 40g of 1-hydroxycyclohexyl phenyl ketone , 40g of ethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com