Frame infill wall using stress self-releasing connecting device and manufacturing method

A connecting device and self-release technology, applied in the direction of walls, building components, building types, etc., can solve the problems of poor deformation capacity of the infill wall, unfavorable rigid connection between the infill wall and the frame, and poor integrity, and achieve good seismic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

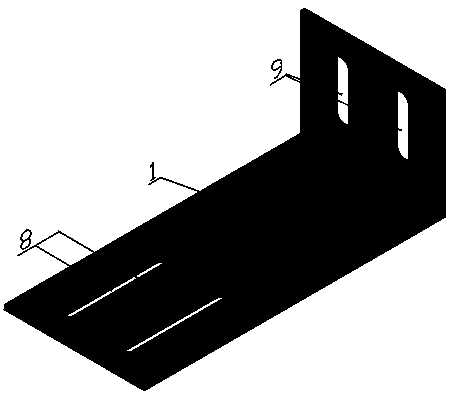

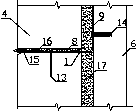

[0043] 1) Select 2mm thick Q235 cold-rolled steel plate, cut it into a rectangular plate with a length of 200mm and a width of 80mm, bend it into an L-shaped thin steel plate with a length of 50mm at the upper end and a length of 150mm at the lower end, and place the Starting from the 10mm distance from the upper edge, process two chutes with a length of 30mm and a width of 10mm. The distance between the two chutes and the edge is 20mm, and the distance between the two chutes is 40mm; the calculation starts at a distance of 10mm from the lower edge. Process two chutes with a length of 50mm and a width of 5mm, the distance between the two chutes and the edges is 20mm, and the distance between the two chutes is 40mm. Processed into the L-shaped stress self-relieving connector (1), a total of 6 were processed;

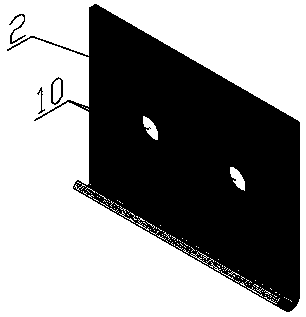

[0044] 2) Choose a 2mm thick Q235 cold-rolled steel plate, cut it into a rectangular plate with a length of 230mm and a width of 80mm, bend it into an L-shaped thin steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com