Plastic pipe fitting-used composite stabilizer and preparation method thereof

A composite stabilizer and plastic pipe fitting technology, which is applied in the field of plastic stabilizers, can solve the problems of poor compatibility, high lead content, and large dosage, and achieve the effects of low cost, low production cost, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

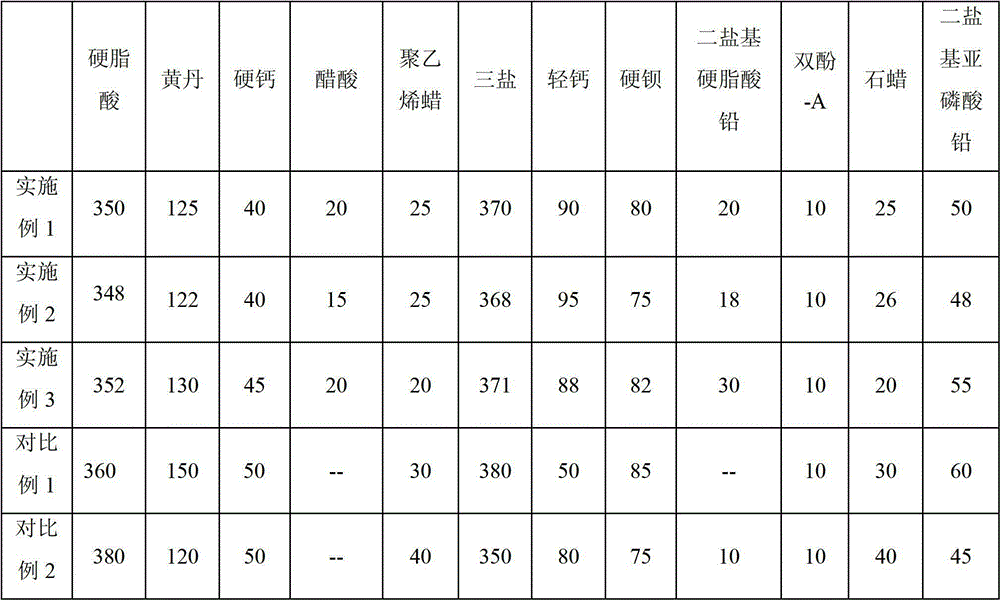

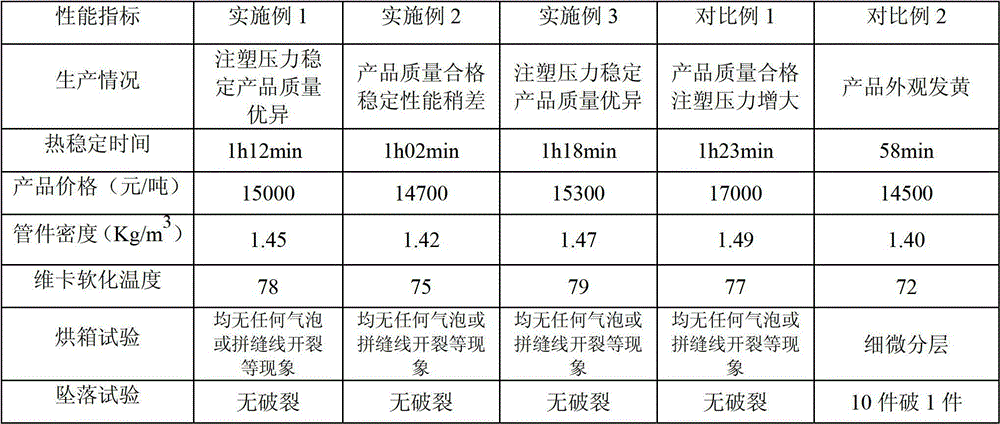

[0051] First put 350g of stearic acid into the reactor and start to heat up. When the temperature rises to 60°C, stearic acid can be seen to melt slowly. Continue to heat up to 140°C. After the stearic acid is completely melted, add 125g of yellow lead at a speed of 1kg / min. (Every time 25g is thrown, stay for 5-10min so that Huangdan can completely react with stearic acid to produce the product lead stearate); after cooling down to 125°C and stirring for 8min, add 20g of acetic acid and react for a further 2min (to make it consume and not completely react 25g polyethylene wax, 370g tribasic lead sulfate, 90g heavy calcium carbonate, 80g barium stearate, 20g dibasic stearic acid Lead, 10g bisphenol-A, 25g paraffin and 50g dibasic lead phosphite; heat preservation and stirring at 80°C, after the materials are stirred evenly, release the materials to obtain the product; it can also be further granulated (or tableted) to form Granular (or flake) product.

Embodiment 2-3

[0053] The specific preparation method is the same as in Example 1, and its specific formulation is as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com