Hydrophobic maintenance seal coat material for roads and preparation method of seal coat material

A hydrophobic and sealing technology, applied in building thermal insulation materials, building components, buildings, etc., can solve problems affecting driving comfort and traffic safety, achieve good hydrophobic and water sealing performance, improve road performance, and alleviate water damage problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

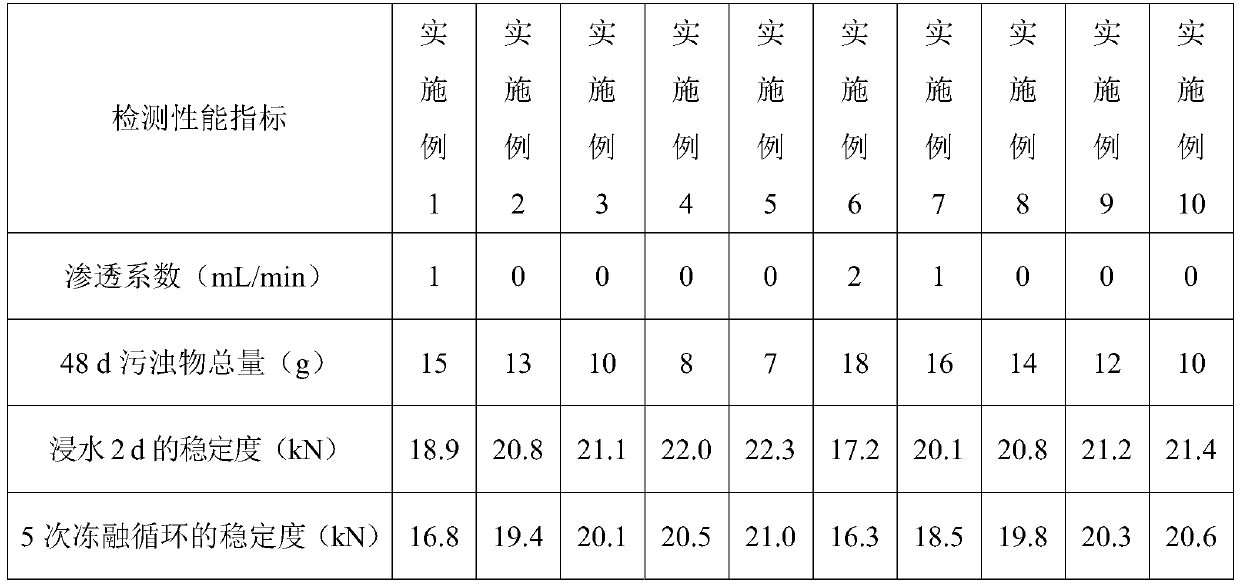

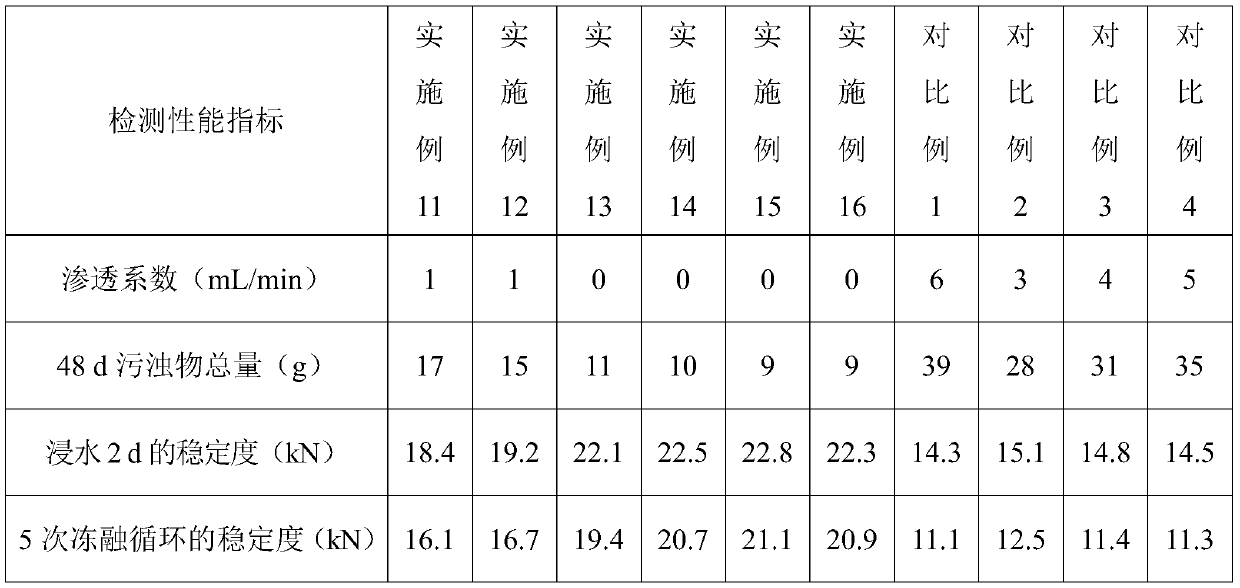

Examples

Embodiment 1

[0059] Embodiment 1 A kind of hydrophobic curing seal material material for road

[0060] 1. Formula:

[0061] Based on the unit mass of the material, the weight ratio of each raw material is as follows: 100 parts of a mixture of cationic emulsified asphalt and epoxy resin, 12 parts of hydrophobic additives, 5 parts of sodium methyl silicate, 2 parts of hexamethyldisilamine, 1 part of sodium fluorosilicate, 2 parts of epoxy dicyclopentadiene epoxy resin, 16 parts of M45 mullite, 6 parts of heavy calcium powder, 4 parts of methyl ethyl ketone, 2 parts of diacetone alcohol, 7 parts of ZCX-1 silica gel powder, 1 part of polyoxyethylene polyoxypropanol amine ether and 2 parts of amino diketone.

[0062] The technical indicators of each raw material are as follows: the ratio of the mixture of cationic emulsified asphalt and epoxy resin is 1:1; the hydrophobic additive is composed of fluorinated polyurethane, carbon nanotube and crystal stone with a mass ratio of 10:0.5:4, and the ...

Embodiment 2

[0070] Embodiment 2 A kind of hydrophobic curing seal material material for road

[0071] 1. Formula:

[0072] Based on the unit mass of the material, the weight ratio of each raw material is as follows: 100 parts of a mixture of cationic emulsified asphalt and epoxy resin, 15 parts of hydrophobic additives, 7 parts of sodium methyl silicate, 3 parts of hexamethyldisilamine, 1.8 parts of sodium fluorosilicate, 2.8 parts of epoxy dicyclopentadiene epoxy resin sizing agent, 18 parts of M45 mullite, 7 parts of heavy calcium powder, 5 parts of methyl ethyl ketone, 3 parts of diacetone alcohol, 9 parts of ZCX-1 silica gel powder 1.4 parts, 1.4 parts of polyoxyethylene polyoxypropanolamine ether and 3 parts of amino diketones.

[0073] The technical indicators of each raw material are as follows: the ratio of the mixture of cationic emulsified asphalt and epoxy resin is 2:1; the hydrophobic additive is composed of fluorinated polyurethane, carbon nanotube and crystal stone with a m...

Embodiment 3

[0081] Embodiment 3 A kind of hydrophobic curing seal material material for road

[0082] 1. Formula:

[0083] Based on the unit mass of the material, the ratio of the parts by weight of each raw material is as follows: 100 parts of a mixture of cationic emulsified asphalt and epoxy resin, 16 parts of hydrophobic additives, 8 parts of sodium methyl silicate, 4 parts of hexamethyldisilamine, 2.2 parts of sodium fluorosilicate, 3 parts of epoxy dicyclopentadiene epoxy resin sizing agent, 20 parts of M45 mullite, 8 parts of heavy calcium powder, 6 parts of methyl ethyl ketone, 4 parts of diacetone alcohol, 9.6 parts of ZCX-1 silica gel powder 1.5 parts, 1.5 parts of polyoxyethylene polyoxypropanolamine ether and 3.5 parts of amino diketones.

[0084] The technical indicators of each raw material are as follows: the ratio of the mixture of cationic emulsified asphalt and epoxy resin is 2:1; the hydrophobic additive is composed of fluorinated polyurethane, carbon nanotubes and cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com