Manufacturing method of pre-packaged lead frame

A manufacturing method and a technology of encapsulating leads, which are applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve problems such as different degrees of bending, deformation of integrated circuit components, and uneven surfaces, so as to ensure surface flatness , Guarantee the overall performance and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the examples, but not limited thereto.

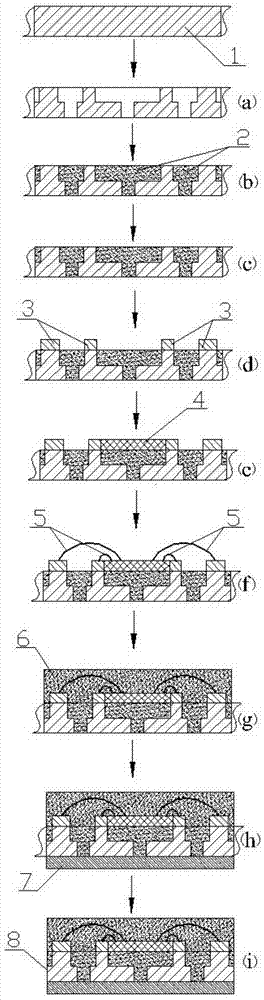

[0025] This embodiment provides a method for manufacturing an integrated circuit element that includes a method for manufacturing a pre-encapsulated lead frame of the present invention. The copper alloy sheet 1 is used as the base material, and the following steps are followed in sequence:

[0026] (1) Etching: Etching the base material of the copper alloy sheet 1 to obtain figure 1 As shown in (a), the specific method of etching is the same as that in the prior art. This embodiment adopts the method of etching through and half etching.

[0027] (2) Pre-encapsulation: It is carried out on the concave-convex mold. The surface of the concave-convex mold is provided with a groove matching the size and position of the etching groove formed by etching, and is provided with a flow channel communicating with the groove. The pre-encapsulation process In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com