Method for preparing graphite oxide/macromolecular water-based cold rolling lubricating additive

A technology of lubricating additives and polymers, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of short service life of cold rolling fluid, large amount of residual carbon, residual iron, poor lubricating performance, etc. Rust level, good lubricating performance, and the effect of improving anti-friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: this embodiment is the preparation method of graphite oxide / polymer water-based lubricating additive for cold rolling, which is realized through the following steps: 1. Put graphite oxide into deionized water, ultrasonically disperse it for 30-60 minutes, and then put Add the graphite oxide suspension into the mixed solution of thionyl chloride and toluene, then under the protection of nitrogen and 50-100°C, reflux for 1-5 days, then centrifuge, discard the supernatant, and remove the precipitated product at 70 Vacuum drying at ~100°C for 12-48 hours to obtain acyl chloride graphite, wherein the ratio of the mass of graphite oxide to the volume of the mixed solution is 1g: 600-1000mL, and the volume ratio of thionyl chloride to toluene in the mixed solution is 1-2: 1; 2. Add the acyl chloride graphite and water-soluble polymer compound prepared in step 1 into N,N-dimethylformamide, then ultrasonically disperse for 2-5 hours, and then react at 80-...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the graphite oxide described in step one is realized through the following steps: adding 5-50 g of dry graphite to the In the salt mixture, after mixing evenly, add 30-300g of potassium-containing strong oxidant under stirring, keep at 30-60°C for 4-12 hours, then add 400-4000mL of deionized water, keep at 60-80°C Continue at high temperature for 30 to 60 minutes, then add 500 to 5000 mL of deionized water and 30 to 300 mL of hydrogen peroxide with a mass concentration of 20% to 40%, stir and react for 10 to 30 minutes, then rinse and filter the reactant with deionized water, Until the pH value of the filtrate is 5-7, the product is dried in a vacuum oven at 40-80°C for 12-48 hours to obtain graphite oxide. Other steps and parameters are the same as those in Embodiment 1.

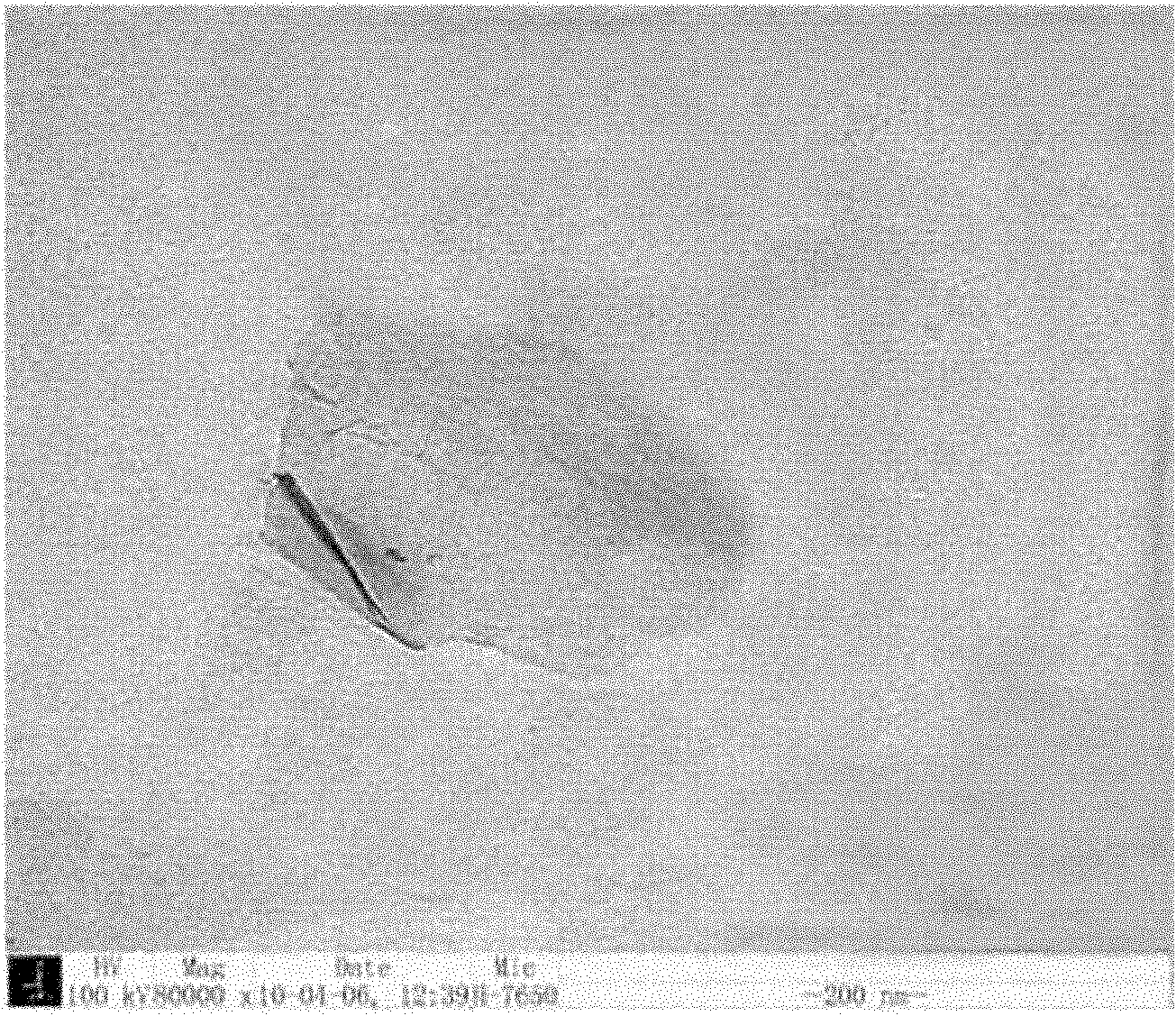

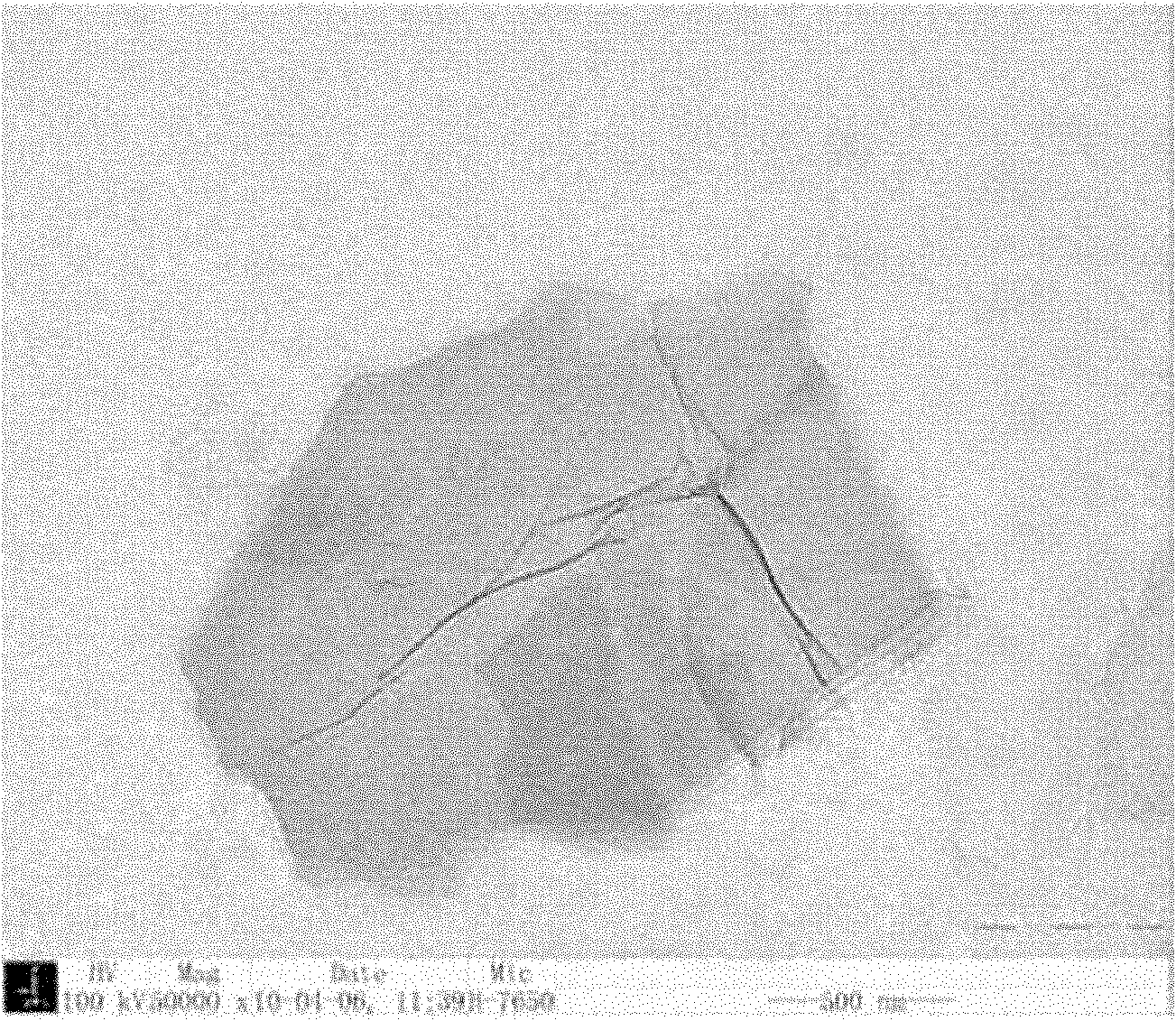

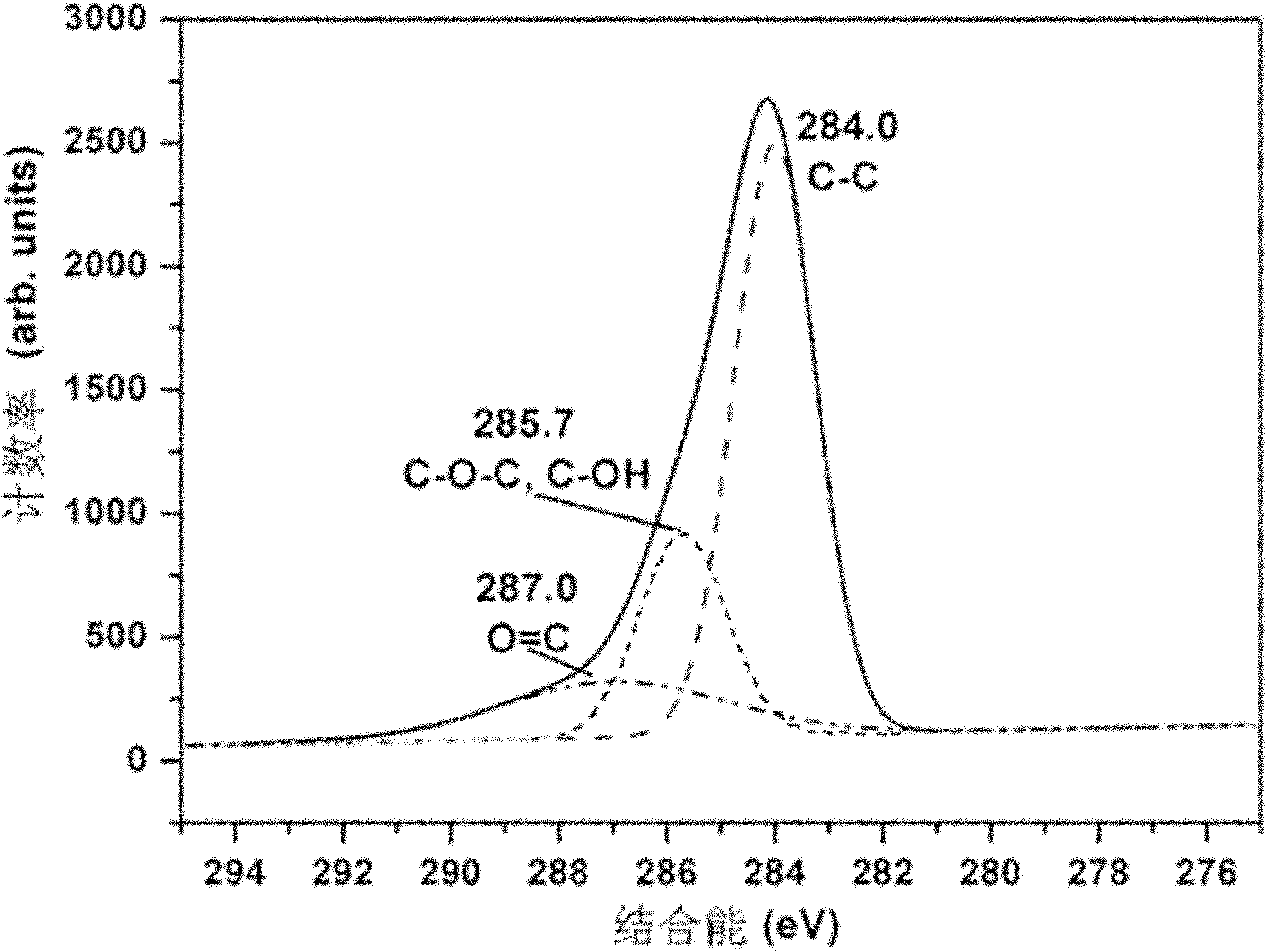

[0019] The transmission electron micrograph of the graphite oxide prepared by the present embodime...

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment is different from Embodiment 2 in that the strong potassium-containing oxidant is potassium permanganate or potassium perchlorate. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com