Steel-structured prefabricated building unit composite wall and assembly method thereof

A technology for composite walls and building units, which is applied in the directions of buildings, building components, building structures, etc., can solve the problem of unsolved prefabricated wall panel joints of prefabricated walls, complex structures of prefabricated walls, and prefabricated walls. Insecurity and other issues, to improve installation quality and installation efficiency, stylish appearance, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

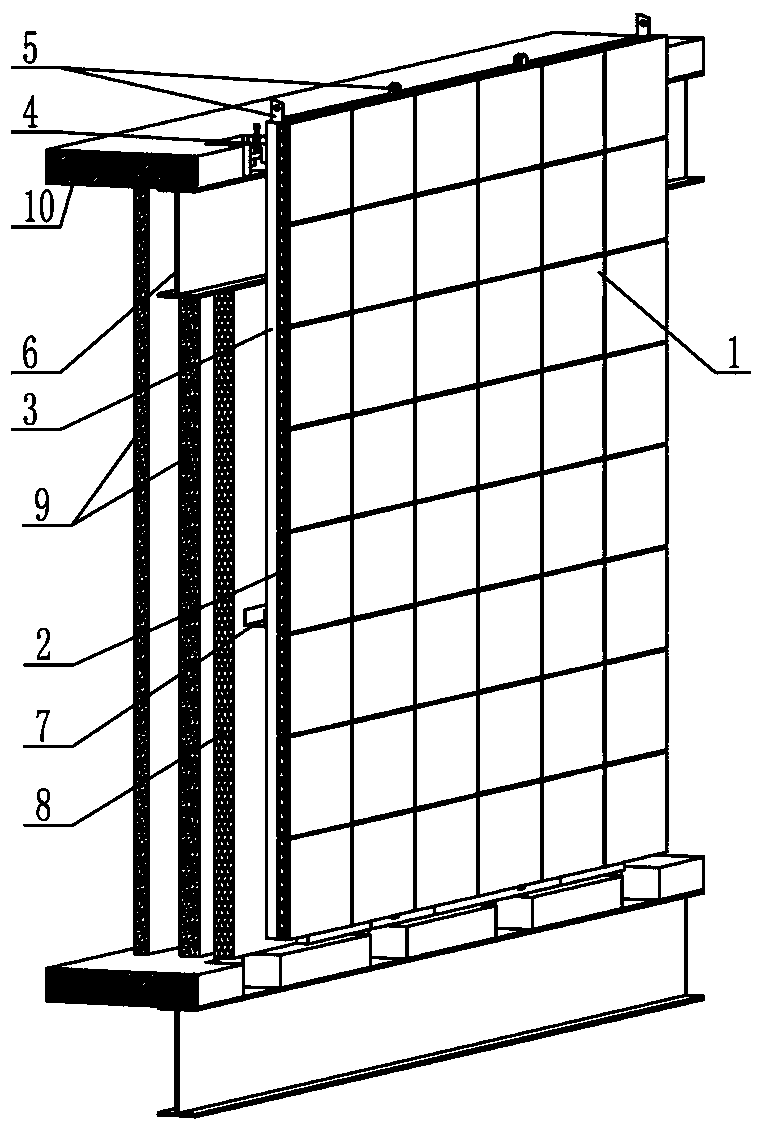

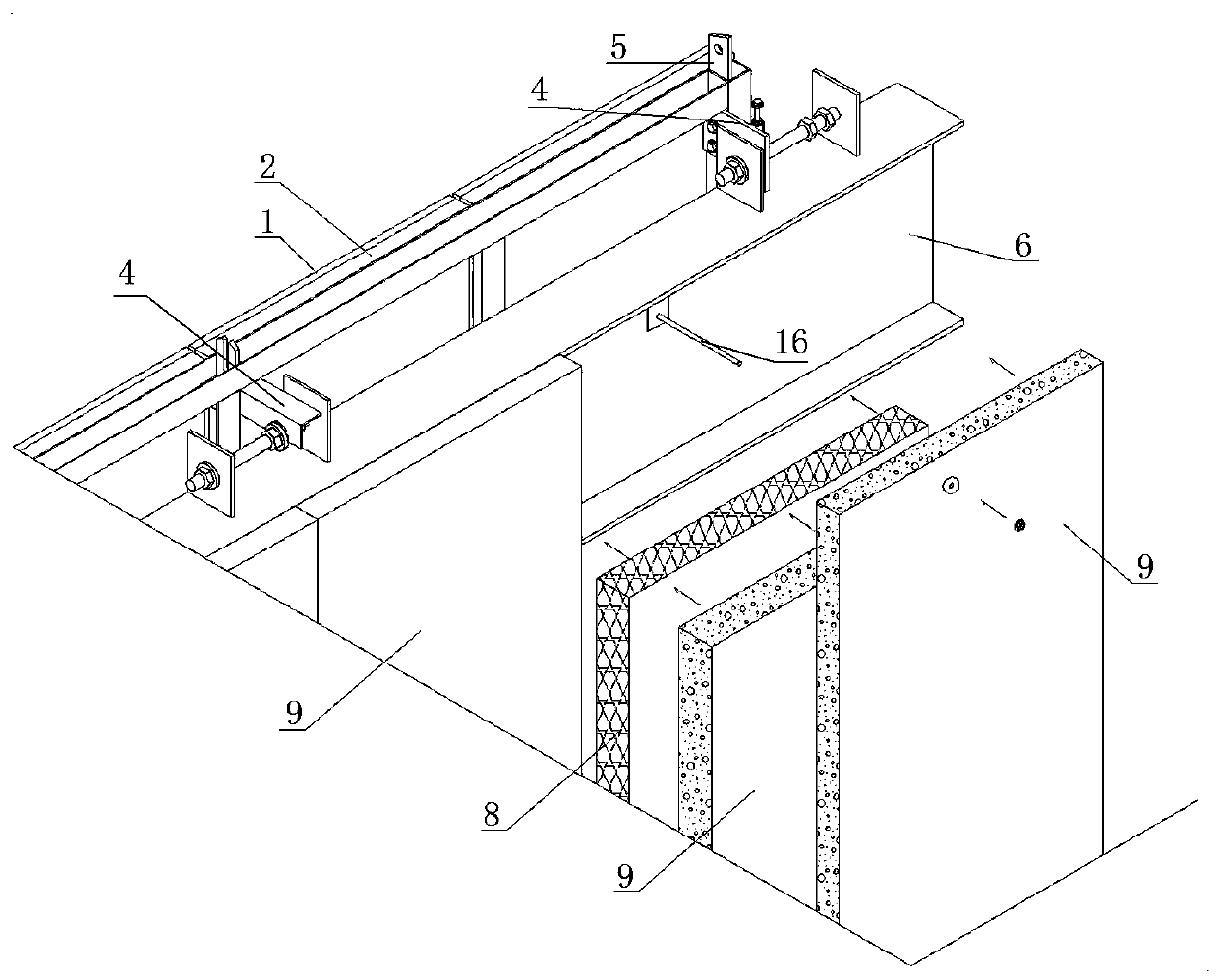

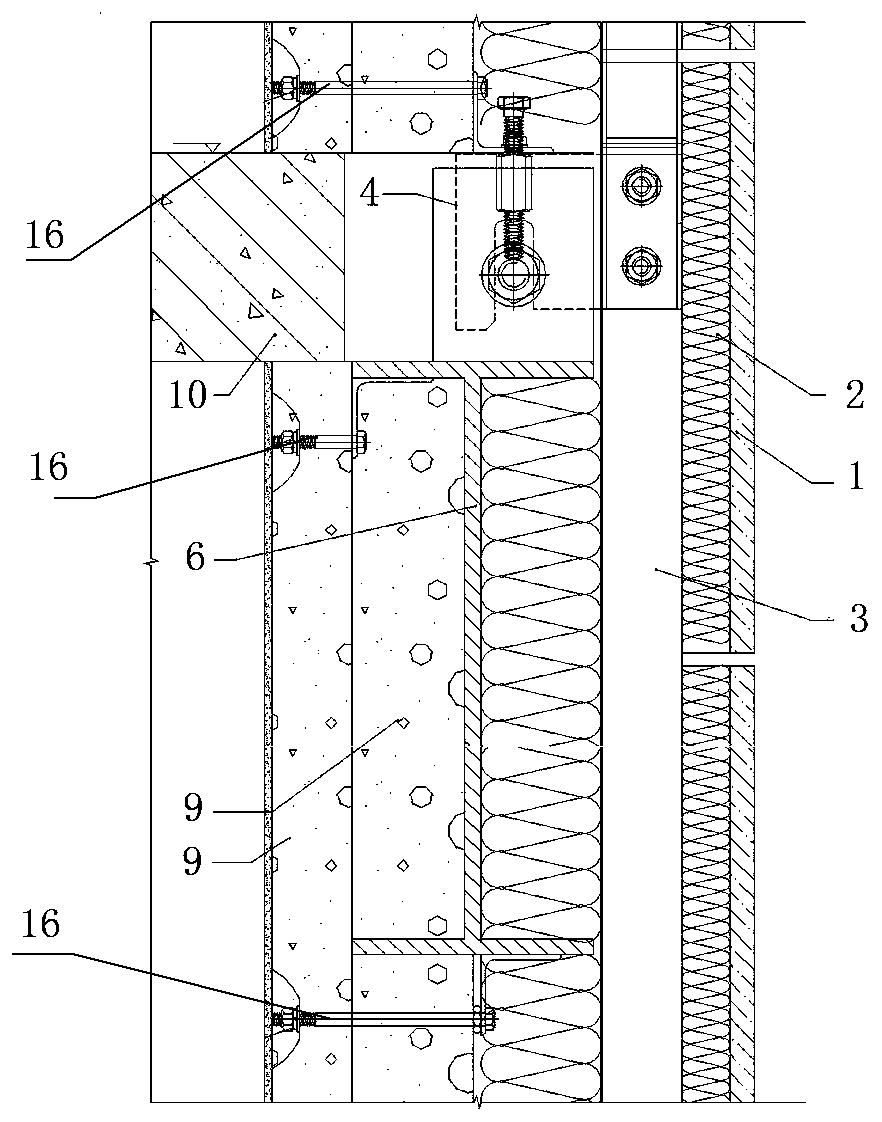

[0041] Such as figure 1 and figure 2 As shown, a steel structure assembled building unit composite wall includes floor slabs 10 and steel beams 6. The unit composite wall includes thermal insulation and decorative unit panels and a main unit wall, and is located between two adjacent floor slabs 10. between the insulation and decoration unit board and the steel beam 6 through a hanging positioning device; a horizontal connecting beam 7 is set between the two steel beams 6, and the connecting beam 7 and the steel beam 6 are used as the connecting hub and the assembly basis, and the The main unit wall is connected with the thermal insulation and decorative unit board to form a whole unit composite wall. Simultaneously connecting beam 7 is as the connection assembly base of inner wall layer, is fixed to become integral inner wall layer by screw rod 17 inner wall layers. By setting the connecting beams, the prefabricated functional components of the unit composite wall are organ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com