Manufacturing method of glazed brick and product thereof

A manufacturing method and technology of polished glazed tiles, which are applied in the field of ceramic tiles manufacturing, can solve problems such as the surface wave shape of polished glazed tiles, achieve a strong three-dimensional pattern and achieve decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

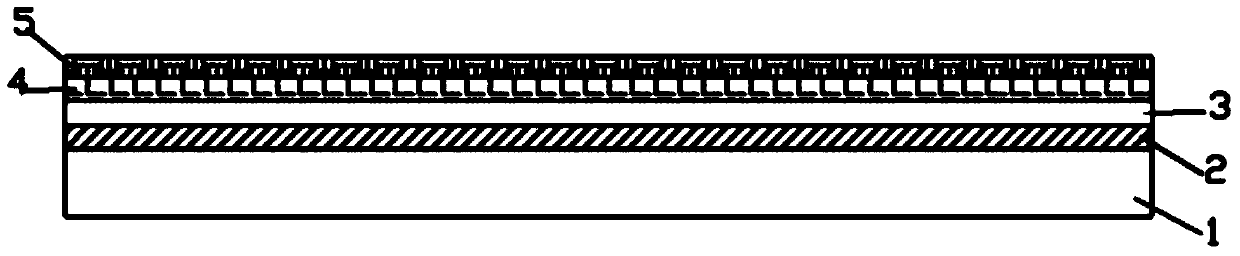

[0024] Such as figure 1 As shown, a kind of polished glazed tile of the present embodiment comprises bottom blank layer 1, A printing layer 2, A transparent glaze layer 3, B printing layer 4, and B transparent glaze layer 5 from bottom to top, wherein the bottom blank The thickness of layer 1 is 8.5mm, the thickness of A printing layer is 0.05mm, the thickness of A transparent glaze layer is 0.7mm, the thickness of B printing layer is 0.03mm, and the thickness of B transparent glaze layer is 0.3mm. It has two layers of transparent glaze and two layers of printing. Under the irradiation of light, the light is transmitted and refracted twice, so that the patterns have a strong three-dimensional effect, complement each other, and have a natural atmosphere, which can well realize the decorative effect of imitating natural stone.

[0025] The above-mentioned manufacturing method of polished glazed tiles with a specification of 1000*1000mm, the steps include in sequence:

[0026] A...

Embodiment 2

[0033] Different from Example 1, the thickness of the bottom base layer 1 in this example is 6 mm, and the thickness of the B printing layer 4 is 0.08 mm. The printing step in the step C is to use the first inkjet printing printing and then the roller In the way of printing, the bottom glaze in the step A is 480g.

Embodiment 4

[0036] Different from Example 1, the thickness of the A printing layer and the B printing layer is 0.1mm, and the amount of the transparent glaze in the step C and the step D in this embodiment is 850g and 950g respectively, and the B transparent glaze Layer 5 has a thickness of 0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com