Concrete bundle superimposed thermal insulation material and preparation method thereof

A thermal insulation material and stacking technology, applied in the field of building materials, can solve problems such as inability to overcome fire safety problems, affecting building use area, not conforming to living habits, etc., and achieve the effect of good heat transfer coefficient, high production efficiency, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

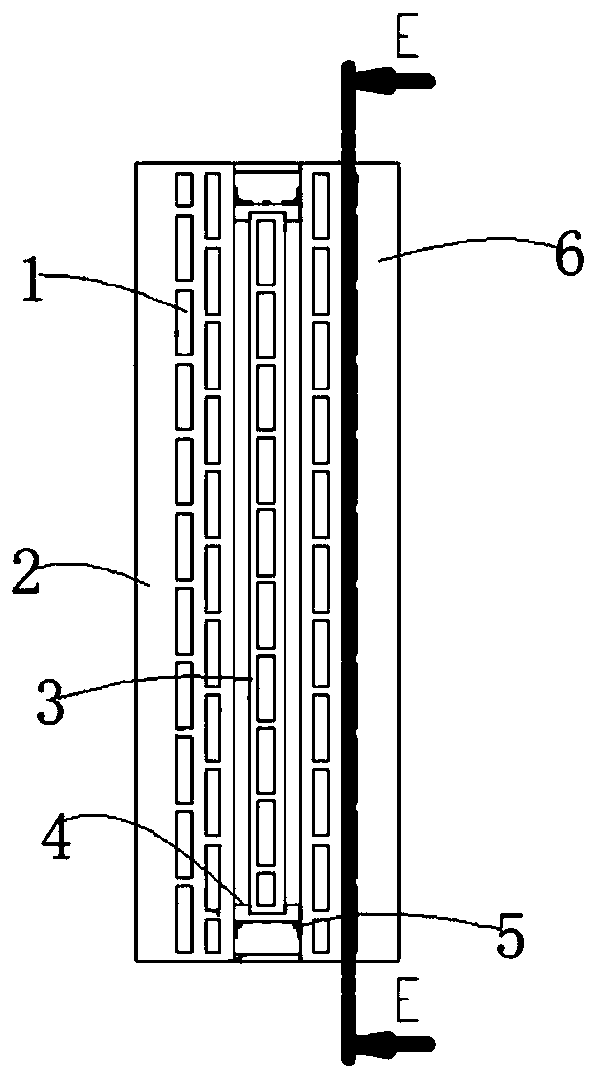

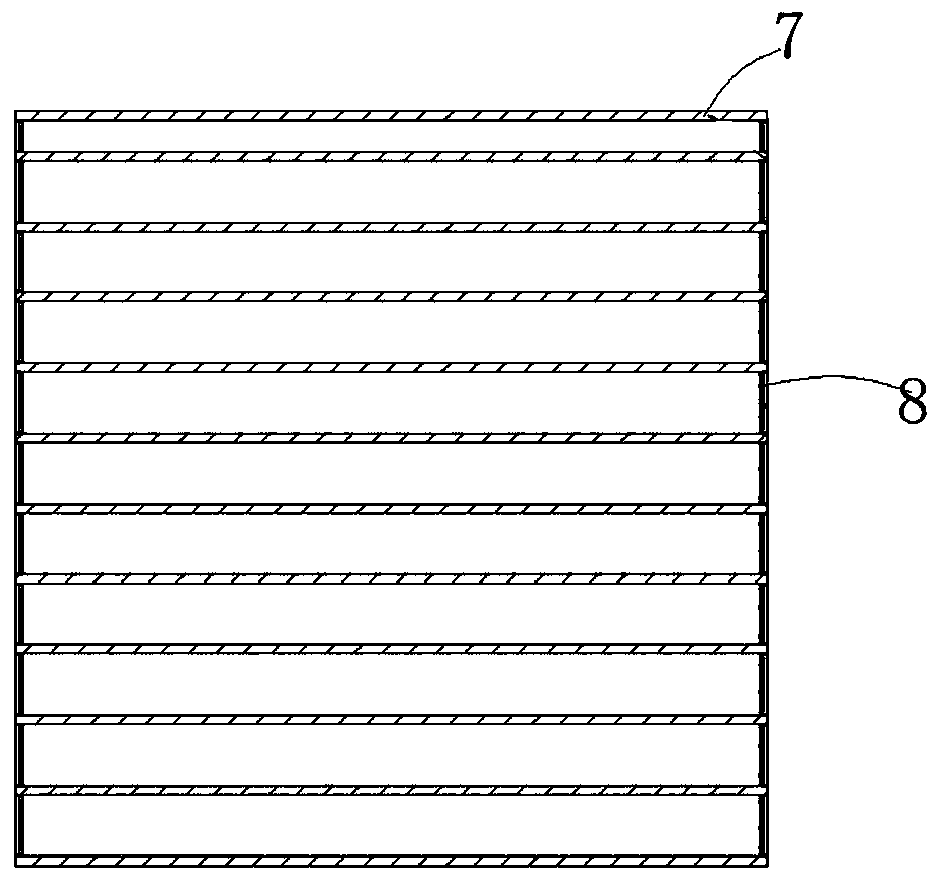

[0026] A concrete bundle laminated thermal insulation material, comprising the following raw materials in proportion by weight: 20% of slag, 20% of fly ash, 20% of biomass ash, 12% of saw foam, 3% of old clothes fiber, 13% of cement, Lightweight aggregate 5%, additive 2‰, light aggregate is perlite, vitrified microbeads or vermiculite, concrete bundle laminated thermal insulation material consists of inner wallboard 6, outer wallboard 2, insulation partition 3, air beam 1 , slot plate 4, installation angle 5, bundle end plugging 8 and concrete 7, the surface of the air bundle 1 is rough surface, and the insulation partition 3 is installed between the inner wall board 6 and the outer wall board 2.

[0027] A method for preparing a concrete bundle laminated thermal insulation material, comprising the following steps:

[0028] S1. Use concrete 7 to seal multiple air bundles 1 in the thermal insulation building material. The surface of the air bundles 1 is rough, and the thickness...

Embodiment 2

[0035] A concrete bundle laminated thermal insulation material, comprising the following raw materials in proportions by weight: 40% of slag, 40% of fly ash, 40% of biomass ash, 19% of saw foam, 13% of old clothes fiber, 40% of cement, Lightweight aggregate 15%, additive 5‰, concrete beam laminated thermal insulation material consists of inner wall panels 6, outer wall panels 2, insulation partitions 3, air beams 1, slot plates 4, installation angles 5, beam end seals 8 and Composed of concrete 7, the surface of the air bundle 1 is a rough surface, and the insulation partition 3 is installed between the inner wall board 6 and the outer wall board 2.

[0036] A method for preparing a concrete bundle laminated thermal insulation material, comprising the following steps:

[0037] S1. Use concrete 7 to seal a plurality of air bundles 1 in the thermal insulation building material, so that the air bundles 1 form a narrow space, and the air has no convection; the data of air layer th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com