MVR concentration and swirling-flow atomization cooperated processing process and system

A collaborative treatment and process technology, applied in the direction of water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of difficult sales of salt, frequent cleaning, large amount of sludge, etc., and reduce operation Cost, reduce the effect of chemical agent dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

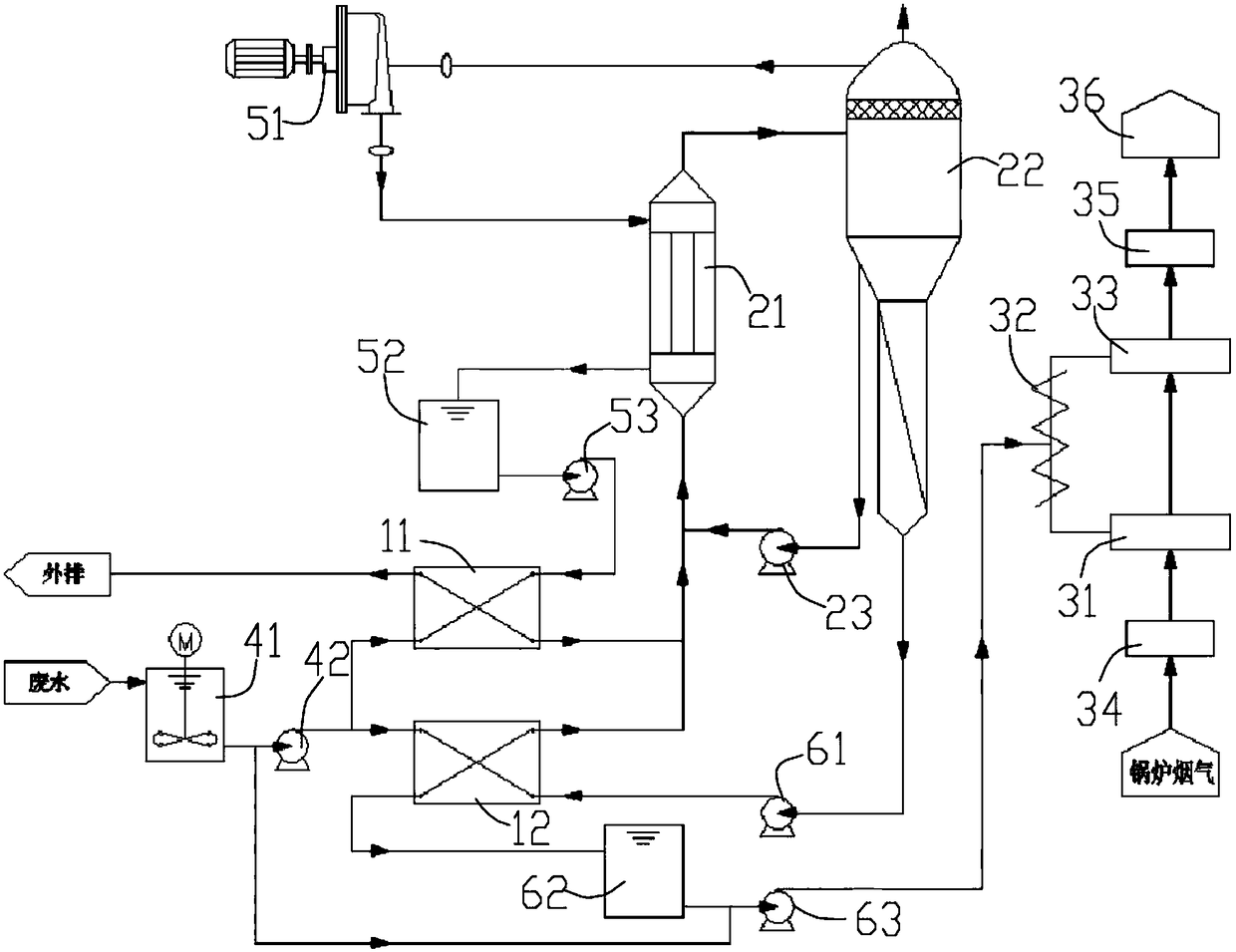

[0039] refer to figure 1 , the MVR concentration and swirl atomization cooperative processing system of this embodiment includes a heat exchanger, an MVR evaporation system and a boiler bypass flue system;

[0040] The MVR evaporation system includes a heater 21, a steam-water separator 22 and a circulation pump 23 arranged between them;

[0041] The boiler bypass flue system includes an air preheater 31, a boiler bypass flue with a swirling atomization chamber 32, and an electrostatic precipitator 33; the air inlet of the air preheater 31 is connected to the boiler flue gas, and its gas outlet is connected to The air inlet of the boiler bypass flue is connected, and the gas outlet of the boiler bypass flue is connected with the air inlet of the electrostatic precipitator 33; the water inlet of the swirling atomization chamber 32 is connected with the concentrated liquid outlet of the steam-water separator 22;

[0042] The water inlet of the heat exchanger is connected with w...

Embodiment 2

[0066] The characteristics of this embodiment are: when the amount of desulfurization wastewater is small, the desulfurization wastewater flows into the water buffer tank by itself, and caustic soda is added to adjust the pH value. Under alkaline conditions, the desulfurization wastewater can be directly pumped to the air through the wastewater atomization pump. The desulfurization wastewater is dried in the swirl atomization chamber of the bypass flue after the preheater.

Embodiment 3

[0068] The feature of this embodiment is: when the boiler load is too low, the high-temperature flue gas in front of the air preheater can be used to transport to the boiler bypass flue system to provide heat for the swirling atomized wastewater to ensure that the wastewater is completely evaporated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com