Patents

Literature

135 results about "Fireproofing Agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Incombustible composition, incombustible construction product using incombustible composition, and method of producing incombustible construction product

InactiveUS20050066859A1High hardnessHigh strengthSolid waste managementCeramicwareFiberFire retardant

Disclosed is an incombustible composition, an incombustible construction product using the incombustible composition, and a method of producing the incombustible construction product. The incombustible composition includes 1 to 80 wt % of organic or inorganic fiber, 1 to 80 wt % of fly ash or bottom ash, 1 to 80 wt % of fire-proofing agent, and 1 to 60 wt % of fire-retardant curing agent. Additionally, the method includes mixing components, constituting the incombustible composition, with each other, and shaping the incombustible composition using a roller press or an autoclave. Therefore, the incombustible composition is advantageous in that it is environmentally-friendly because it contains waste materials, and that it has excellent hardness, strength, and water resistance. Other advantages are that its production costs are relatively low, and that it has excellent incombustibility, depending on the contents of the components constituting the incombustible composition.

Owner:CHOI JUN HAN

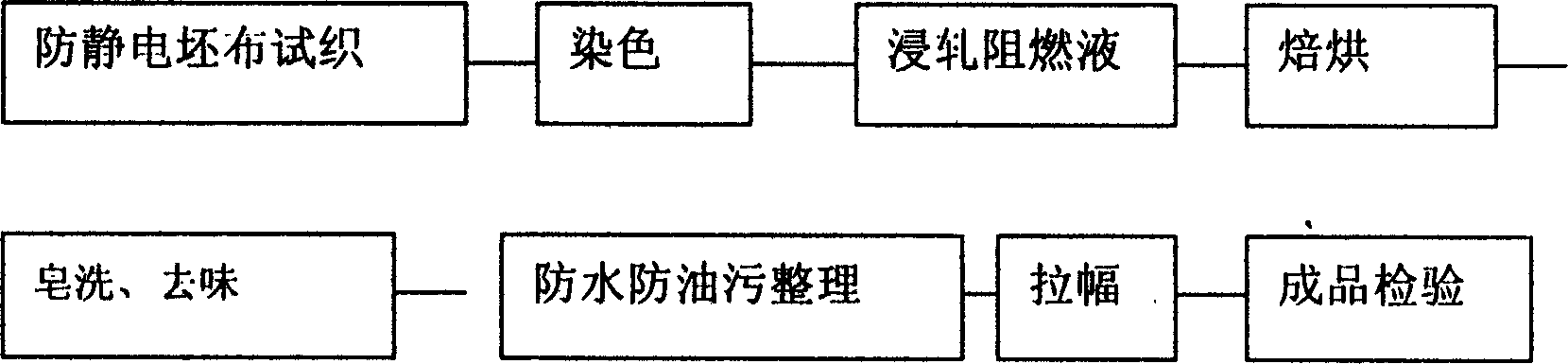

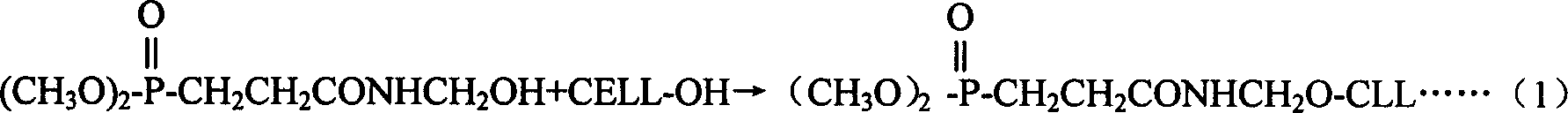

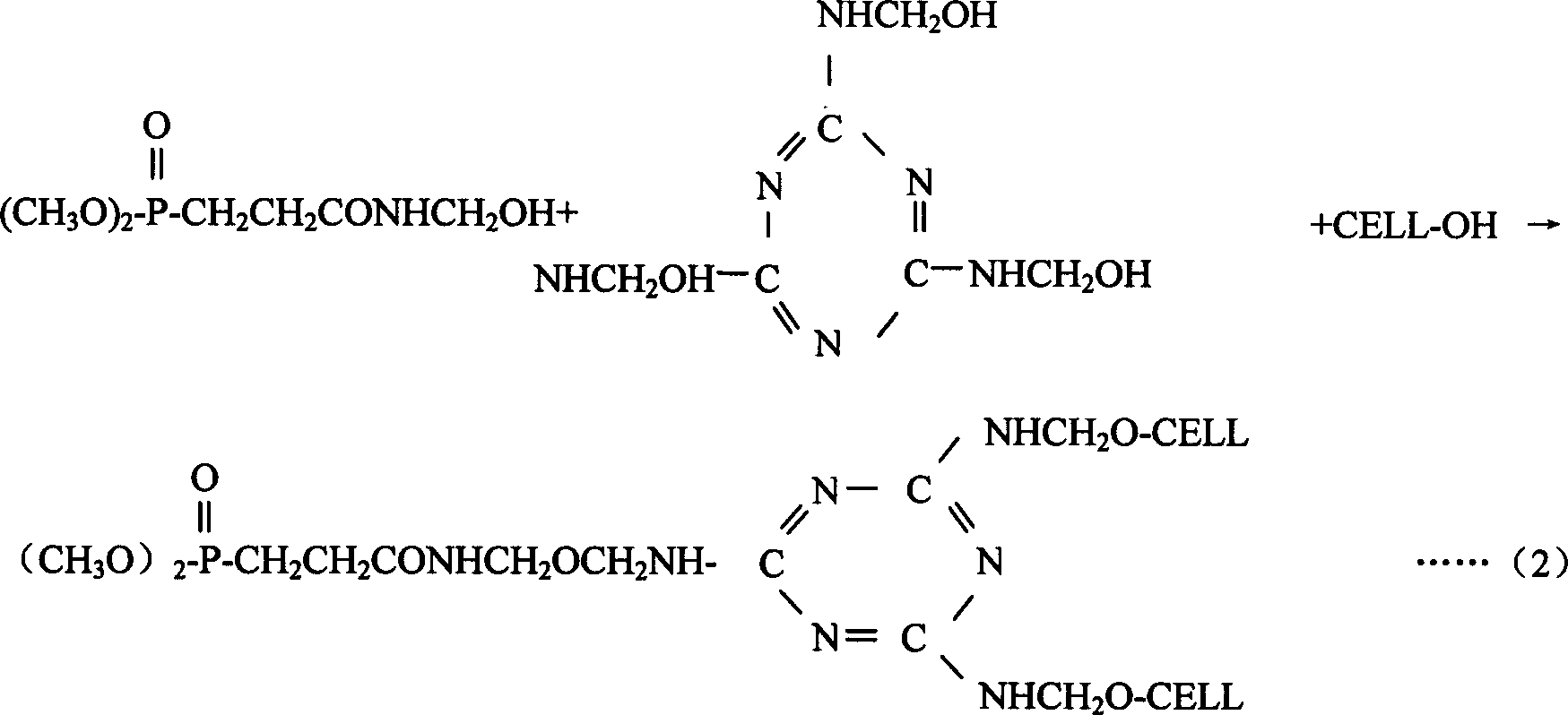

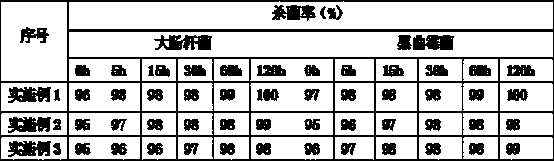

Method for producing anti-static flame retardant, water-proof and oil-proof natural fibrous fabric

InactiveCN1554817AConform to project technical index requirementsEase of evaluationFibre treatmentWoven fabricsMetal fibersEngineering

The production process includes trial weaving antistatic grey cloth, dipping fireproof liquid, roasting, soaping, deodorizing, waterproof and anti-fouling finishing, framing and inspection. The antistatic method is to add organic conducting fiber or conducting metal fiber; the dipping fireproof liquid is to finish the natural fiber fabric with fireproof agent and crosslinking agent; and the waterproof and anti-fouling finishing adopts fluoric compound as waterproof and anti-fouling agent. The natural fiber fabric may contain small amount of chemical fiber and has the functions of resisting static electricity, resisting flame, resisting water and resisting oil stain.

Owner:江苏东升艾克科技股份有限公司

Water flame-retardant paint

The water flame-retardant paint consists of emulsion, deionized water, filming assistant, dispersant, wetting agent, thickener, defoaming agent, fireproof agent, fireproof assistant, stuffing and pigment. The fireproof agent and fireproof assistant consists of Sb2O3, decabromodiphenyl oxide, nano zinc oxide colloid, aluminium hydroxide, native soda and zinc borate. The paint has the features of being waterproof, aging resistant, mildewproof and fireproof.

Owner:王崇高

Perfuming or flavoring microcapsules comprising a fireproofing agent

InactiveUS7204998B2Impart tasteSimple preparation processCosmetic preparationsOrganic detergent compounding agentsFlavorAdditive ingredient

Perfuming or flavoring microcapsules that include a fireproofing agent in addition to a perfuming or flavoring ingredient and a carrier material, so that the microcapsules can reduce the occurrence or an explosion of reduced violence when suspended in hot air during their preparation. Also, methods of making these microcapsules and their use in perfumed, food, beverage or pharmaceutical products.

Owner:FIRMENICH SA

Water-based coating

ActiveCN104017445AImprove defoaming abilityWell mixedFireproof paintsAntifouling/underwater paintsExtensibilityWater based

The invention discloses a water-based coating which is characterized by comprising the following components by weight parts: 20-30 parts of water, 20-25 parts of an acrylic emulsion, 0.3-0.5 part of a wetting agent, 0.1-0.3 part of a de-foaming agent, 15-20 parts of titanium dioxide, 10-15 parts of talcum powder, 0.3-0.5 part of a fireproof agent and 0.2-0.4 part of an antibacterial agent. The coating disclosed by the invention is reasonable in composition, low in cost, good in compatibility among the components, environment-friendly, mildew-proof and flame-retardant, and has excellent application values; a natural antibacterial agent and an inorganic antibacterial agent are mixed for use, so that the problems of poor stability due to single use of the natural antibacterial agent or pollution caused by single use of an organic antibacterial agent and high cost due to single use of the inorganic antibacterial agent are solved; due to combined use, the mildew-proof effect is more lasting; the film-forming drying time is short, the hardness is good, and the extensibility and the heat resistance are good.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Environment-friendly coating

ActiveCN104017446AReasonable compositionLow costAntifouling/underwater paintsPaints with biocidesAntibacterial agentCompatibilization

The invention discloses an environment-friendly coating which comprises the following components by weight parts: 25-30 parts of water, 1-2 parts of plant alkaloid, 1-3 parts of a wetting agent, 2-4 parts of a dispersant, 2-4 parts of a de-foaming agent, 15-25 parts of titanium dioxide, 20-30 parts of diatomite, 10-15 parts of talcum powder, 15-20 parts of an acrylic emulsion, 1-2 parts of a mildew-proof agent, 2-4 parts of a fireproof agent and 1-2 parts of an anticorrosive antibacterial agent. The coating is reasonable in composition, low in cost, good in compatibility among the components, environment-friendly, mildew-proof, antibacterial, anticorrosive, insect-proof and flame-retardant, and has excellent application values; harmful substances such as formaldehyde emitted by furniture and the like can be absorbed; a natural antibacterial agent and an inorganic antibacterial agent are mixed for use, so that the stable performance of the coating is ensured; the film-forming drying time is short, the hardness is good, and the extensibility and the heat resistance are very good.

Owner:营口新美世粉末涂料有限公司

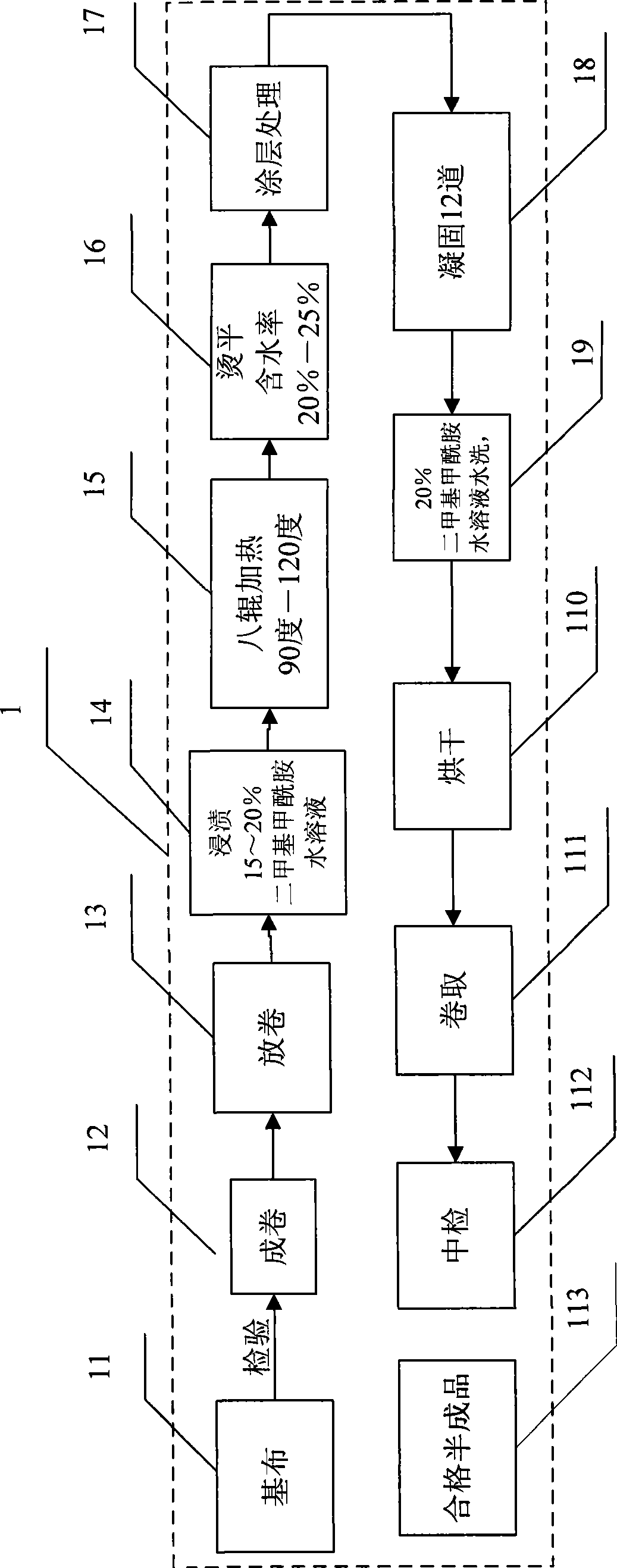

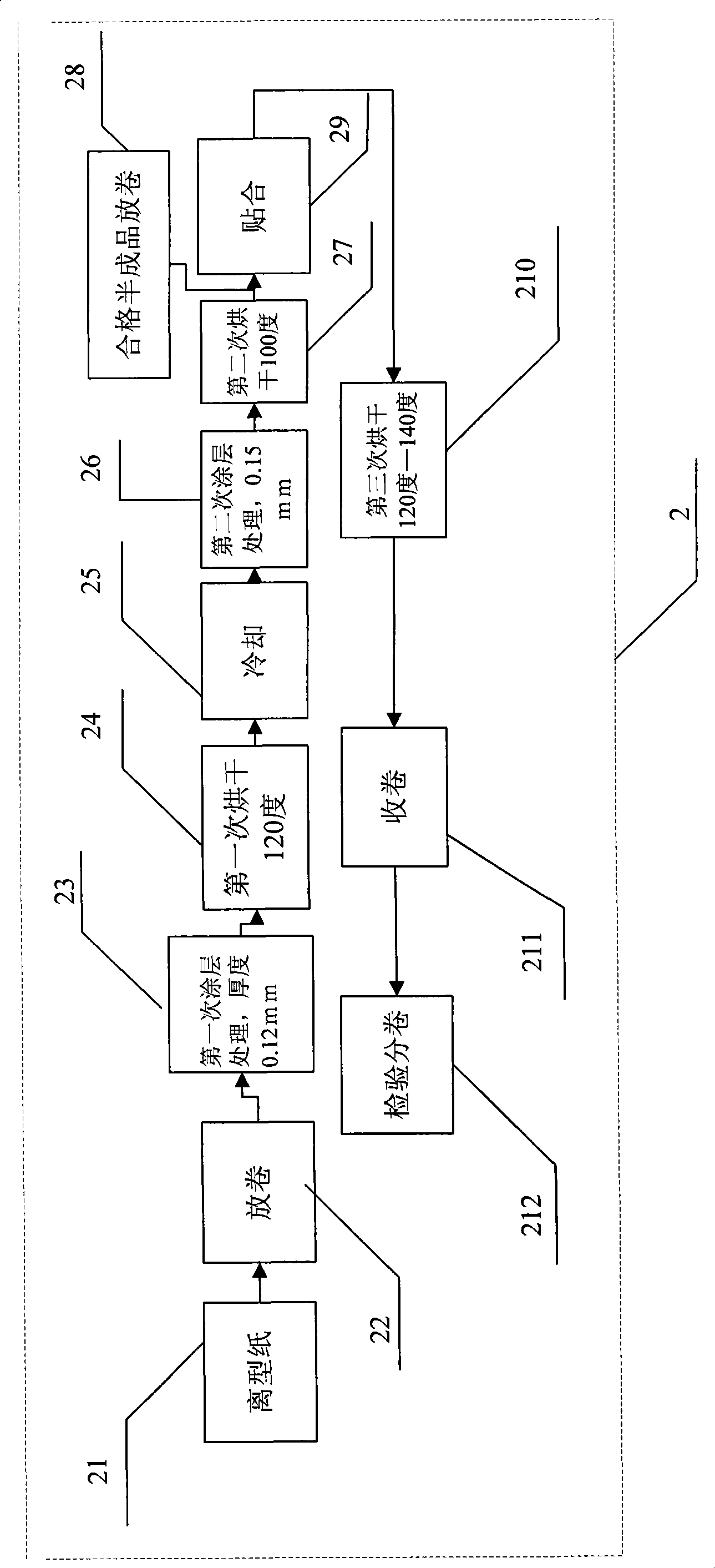

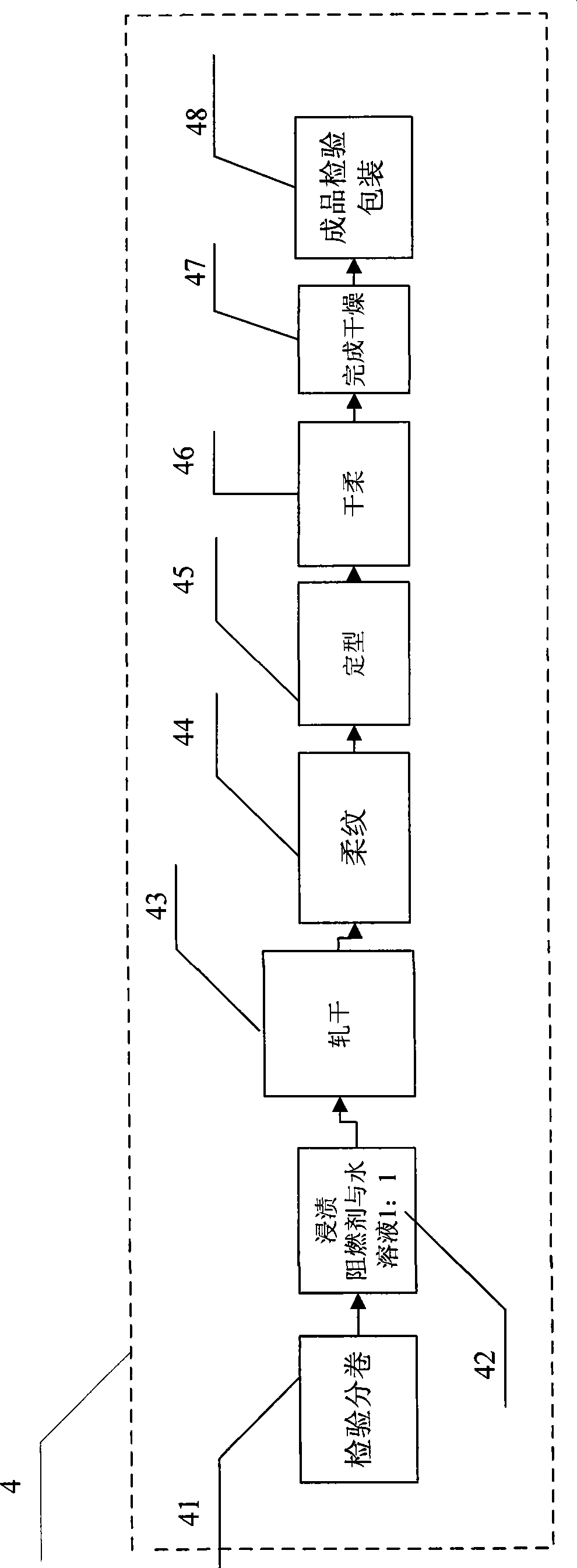

Flame-retardant leather and method of producing the same

InactiveCN101469515ADoes not affect textureDoes not affect performanceFabric breaking/softeningSynthetic resin layered productsFireproofingWork in process

The invention relates to a fire-retardant leather and manufacturing process thereof, comprising a semi-finished product formula, a face-covering formula, and a following formula, all with flame retardant agent added. The manufacturing process for the fire-retardant leather includes a semi-finished product process, a face-covering process and a following flame retardancy. The semi-finished product process includes base cloth coiling after check, putting the coil into a dimethylformamide water solution for a first immersion; heating and ironing by an eight roller; coating layer processing, concreting; water washing in the dimethylformamide water solution; drying; winding, middle checking. The face-covering includes unreeling the semi-finished product, jointing the treated release paper; drying for the third time, checking and bundling. The following flame retardancy includes putting the finished leather into a steam kneading machine for steam kneading, adding a fireproofing agent in the kneading process; immersing in the flame retardant and water solution; rolling drying, ripple softening, forming, dry softening, drying; checking and packing the product. Leather manufactured by the method has flame retardancy greatly improved.

Owner:NINGBO BRIDGE SYNTHETIC LEATHER

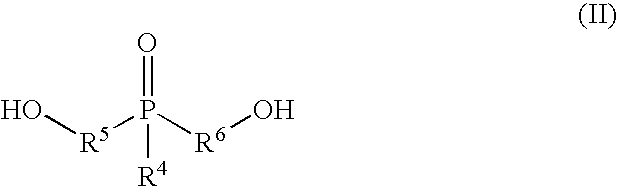

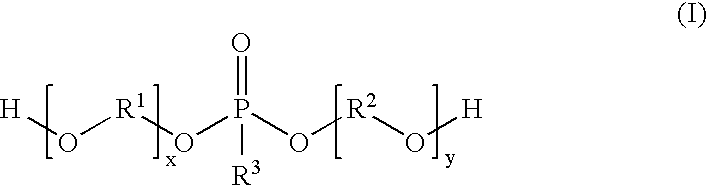

Thermoplastically processable polyurethanes (TPU) with self-extinguishing properties, a process for their preparation and their use

The present invention relates to thermoplastically processable polyurethane elastomers (TPU) with tensile strengths of >35 MPa (measured in accordance with EN ISO 527-3), with shrinkages of <3% and with self-extinguishing properties based on the use of at least one flameproofing agent which can be built in, a process for their preparation and their use.

Owner:BAYER AG

Polycarbonate/ABS alloy, its preparation method and its application

The invention discloses a polycarbonate / ABS alloy, its preparation method and its application. A raw materials formula of the polycarbonate / ABS alloy comprises the following components by weight parts: 25-50 parts of PC, 20-50 parts of PC reworked material, 20-30 parts of ABS reworked material, 5-10 parts of MBS, 5-8 parts of TPP, 0.3-0.5 part of FR2025 fire retardant, 0.5-2 parts of titanium dioxide, 0.1-0.5 part of anti-oxidant1010, 0.1-0.5 part of anti-oxidant168, 0.1-0.5 part of ultraviolet resistance agentUV-531, 0.03-0.08 part of proliferation powderEBS, 0.02-0.06 part of ultramarine powder, 0.02-0.4 part of iron oxide red powder and 0.005-0.01 part of high temperature resistance fluorescent yellow powder. The alloy of the invention has the characteristics of high performance, high flame retardation, high impact, high stability, antistatic property and the like, and can be used for producing intelligent ammeter housing and terminal strips.

Owner:扬州瑞邦化工技术有限公司

Cold resistant polycarbonate/ABS alloy for intelligent ammeter shell and preparation method thereof

ActiveCN102311628AImprove performanceConvenient amountTime integral measurementFluorescenceULTRAMARINE BLUE

The invention discloses a cold resistant polycarbonate / ABS alloy for an intelligent ammeter shell and a preparation method thereof. Raw materials of the cold resistant polycarbonate / ABS alloy for an intelligent ammeter shell comprise the following components of: by weight, 25-50 parts of PC, 20-50 parts of a PC reworked material, 20-30 parts of an ABS reworked material, 5-10 parts of MBS, 5-8 parts of triphenyl phosphate, 0.3-0.5 part of an FR 2025 fire retardant, 0.5-2 parts of titanium dioxide, 0.1-0.5 part of an anti-oxidant 1010, 0.1-0.5 part of an anti-oxidant 168, 0.1-0.5 part of an ultraviolet resistance agent UV-531, 0.03-0.08 part of a diffusion powder EBS, 0.02-0.06 part of an ultramarine blue powder, 0.02-0.04 part of an iron oxide red powder, 0.005-0.01 part of a high temperature resistance fluorescent yellow powder, and 2-5 parts of a cold resistant agent 2602. The alloy provided by the invention has characteristics of high performance, high cold resistance, high flame retardation, high impact resistance, high stability, antistatic performance and the like, and is suitable for the preparation of an intelligent ammeter shell in a cold region as well as a terminal row.

Owner:江苏振东电气设备有限公司

Polycarbonate/glass fiber alloy used for cold resistant housing of intelligent water meter and preparation method thereof

ActiveCN102311625AImprove performanceSave energyTime integral measurementGlass fiberULTRAMARINE BLUE

The invention discloses polycarbonate / glass fiber alloy used for the cold resistant housing of an intelligent water meter and a preparation method thereof. The polycarbonate / glass fiber alloy comprises, by weight, 30 to 50 parts of PC, 30 to 50 parts of an PC recycled material, 0.3 to 0.5 part of a fireproof agent FR2025, 0.5 part to 2 parts of titanium dioxide, 9.5 to 11.5 part of glass fiber, 2 to 5 parts of EMA, 0.1 to 0.5 part of an anti-oxidant1010, 0.1 to 0.5 part of an anti-oxidant 168, 0.3 to 0.5 part of an ultraviolet resistant agent UV-531, 0.03 to 0.08 part of diffusion powder EBS, 0.04 to 0.08 part of ultramarine blue powder, 0.02 to 0.04 part of iron oxide red powder 0.005 to 0.01 part of high temperature resistant florescent yellow powder and 2 to 5 parts of a cold resisting agent 2602. The alloy has the characteristics of high performance, high cold resistance, high fire retardancy, high impact, high stability, resistance to static electricity and the like, and can be used for preparing the housing of intelligent water meters used in chilly regions and for preparing terminal rows.

Owner:江苏百凌电器有限公司

Fibrous reinforcement suitable as a fireproofing agent

ActiveUS20040197539A1Fibre treatmentSynthetic resin layered productsFireproofingThermosetting polymer

A fibrous reinforcement including a fibrous support treated throughout or covered at least partially on one of its surfaces with a compound containing: i) one or more thermosetting prepolymers having a softening temperature of 150° C. or lower and / or one or more thermoplastic polymers having a glass transition temperature lower than 300° C.; and ii) one or more inorganic phosphorus compounds. The treatment ratio of the fibrous support with the inorganic phosphorus compound(s) falls within the range of 2%-20% by weight. The fibrous reinforcement is suitable for use as a fireproofing agent.

Owner:HEXCEL REINFORCEMENTS SAS

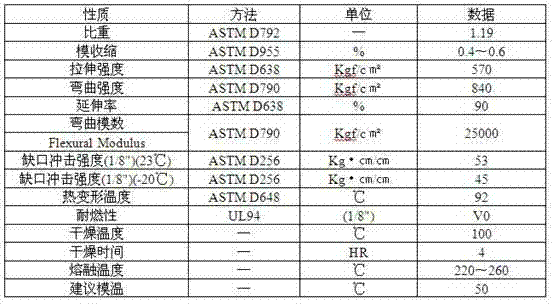

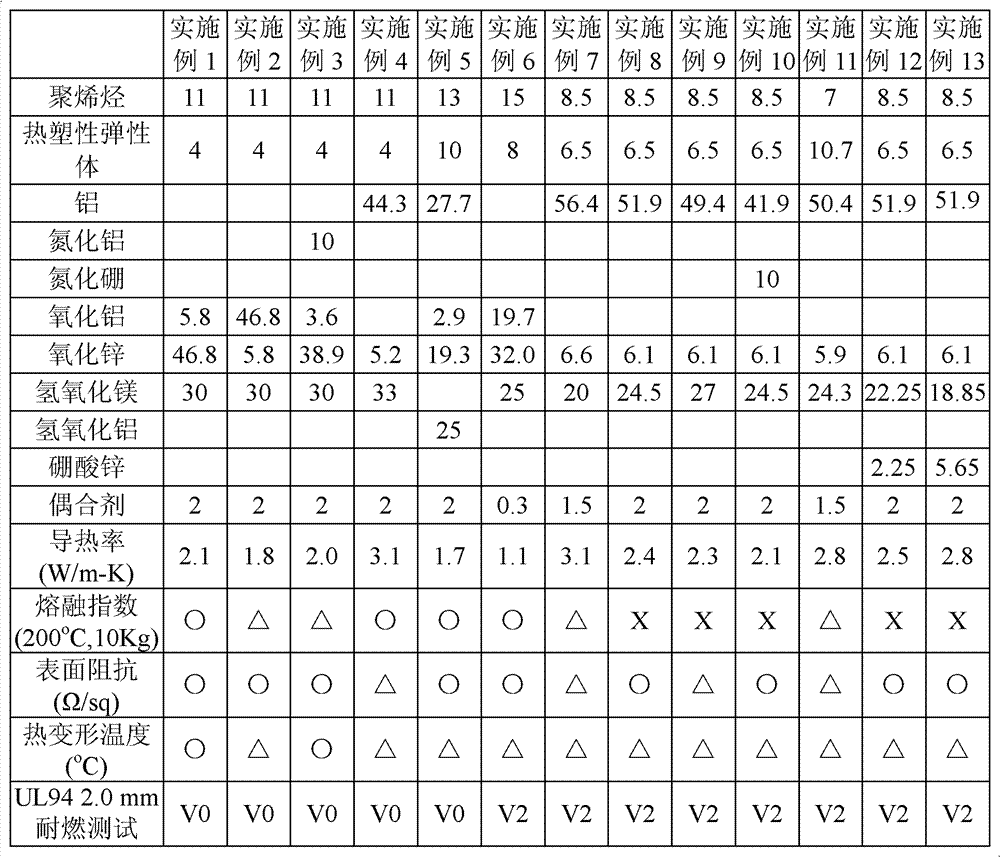

Flame-retardant thermal-conductive plastic composition

InactiveCN103113647AImprove stabilityImprove cooling effectHeat-exchange elementsHeat deflection temperaturePolymer science

The invention discloses a flame-retardant thermal-conductive plastic composition. The flame-retardant thermal-conductive plastic composition comprises the following components in percentage by weight: 5%-45% of polyolefin A, 3%-25% of thermoplastic elastomer B, 35%-85% of thermal-conductive filler C, 5%-55% of non-phosphorus, non-nitrogen and non-halogen fire-proofing agent D and 0.5%-6% of coupling agent E. The composition disclosed by the invention has a fireproof level of UL94VL or higher, a thermal conductive coefficient bigger than 1.0 Watts / m-K, thermal deformation temperature of 105 DEG C or higher and high surface impedance. Besides, the composition has good processability and can be formed through injection-molding, extruding or hot-pressing molding.

Owner:KENNER MATERIAL & SYST

Preparation method of fireproof insulation board and adopted impregnating compound

The invention provides a preparation method of a fireproof insulation board and an adopted impregnating compound. The preparation method of the fireproof insulation board comprises the following steps: 1) producing monofilaments and coating the impregnating compound; 2) acupuncturing to prepare a fiber mat; and 3) directly carrying out hot press moulding on the acupunctured mat, so that the fireproof insulation board is obtained, wherein the impregnating compound comprises a binding agent, a fireproof agent and a hydrophobing agent. Compared with the prior art, the preparation method of the fireproof insulation board has the characteristics that a production technology is simple, production efficiency is high, a production process is environment-friendly, energy consumption is low, yield is high, fireproof performance of the fireproof insulation board product is good, peel strength of the fireproof insulation board product is good, the fireproof insulation board product hardly cracks in a using process, and cost is relatively low.

Owner:NINGBO QIUXIN NEW MATERIAL TECH

Bionic log processing method

ActiveCN105082270AHigh strengthImprove performanceLaminationLamination apparatusPreservativeWood wool

The invention discloses a bionic log processing method. The bionic log processing method is characterized by comprising the step one of raw material preparing and preprocessing; the step two of raw material preparation; the step three of high-temperature boiling dyeing; the step four of drying; the step five of sorting and storage; the step six of gluing and glue mixing by adding waterproof agents, fireproof agents and preservatives; the step seven of gradual change of wood flour of a veneer slab and directed pavement of wood wool; the step eight of premoulding of the veneer slab to form a veneer; the step nine of powdery gluing of the veneer; the step ten of overlaying of bionic log slabs in a multilayer tapered overlaid structure manner and cold pressing of the bionic log slabs; the step eleven of partial impregnation; the step twelve of hot pressing of the bionic log slabs in a multilayer tapered overlaid structure manner; and the step thirteen of trimming of finished bionic log products and storage of the finished bionic log products.

Owner:孙建民

Method for preparation of flame-proof chinlon gluing buckle

ActiveCN101116566AImprove flame retardant performanceImprove securityBucklesPulp and paper industryFire retardant

The invention relates to a manufacturing method of a flame retardant Velcro, including procedures as follows: the Velcro is put into a tincture machine to be cleaned at first, then the Velcro is bleached; and then the bleached Velcro is dehydrated and is friezed by a friezing machine; the processed Velcro is dried by baking, the dried Velcro is sunk into fireproof agent in a tincture machine, after soaking, the Velcro is dehydrated; then the dehydrated Velcro undergoes fire retardant treatment and gum on a gum machine, finally the Velcro is dried by baking. The Velcro manufactured by the method of the invention is not easy to burn with flame retardant invention, thereby being applied to vehicles such as the airplanes and the automobiles to improve the safety in use.

Owner:WUXI PAIHO TEXTILES CO LTD

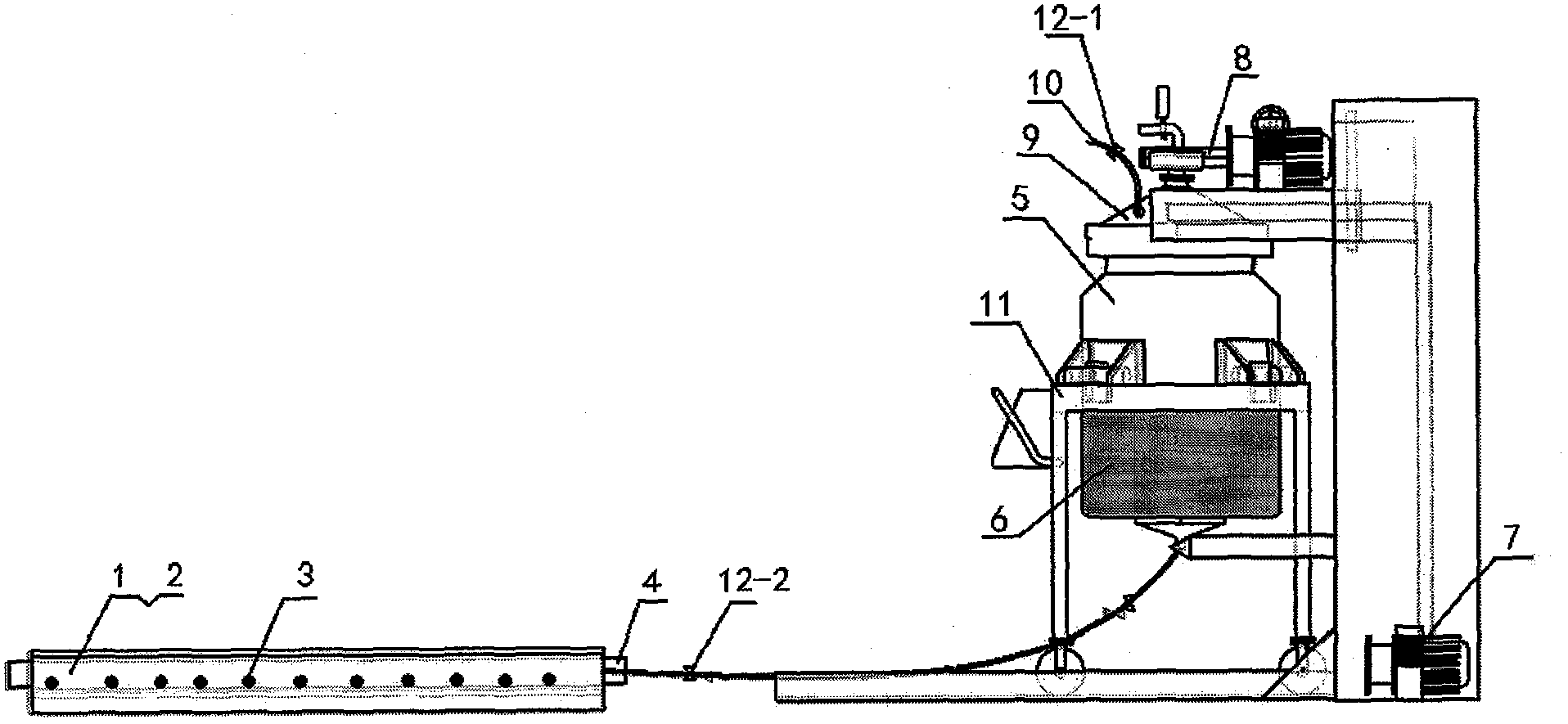

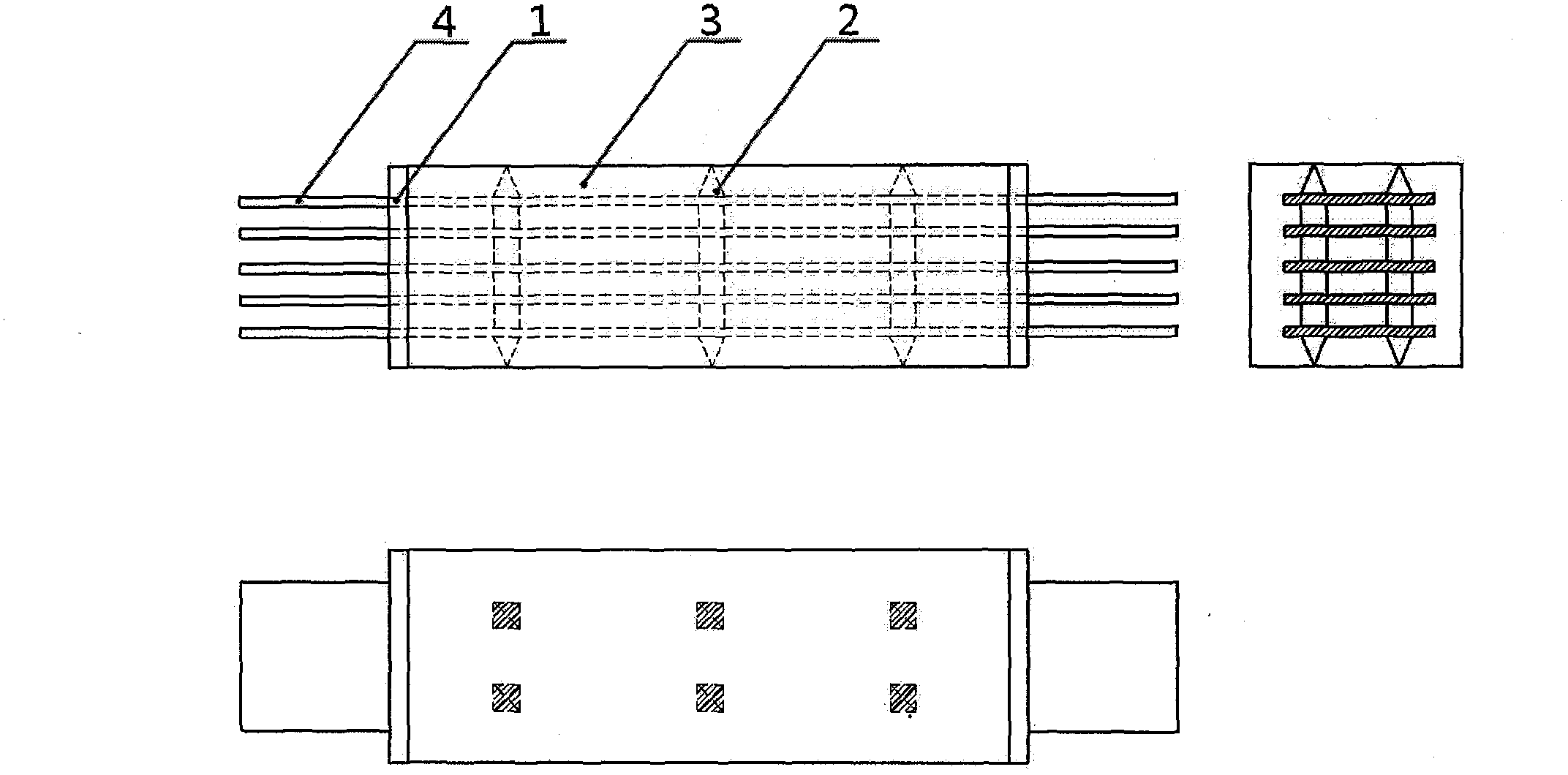

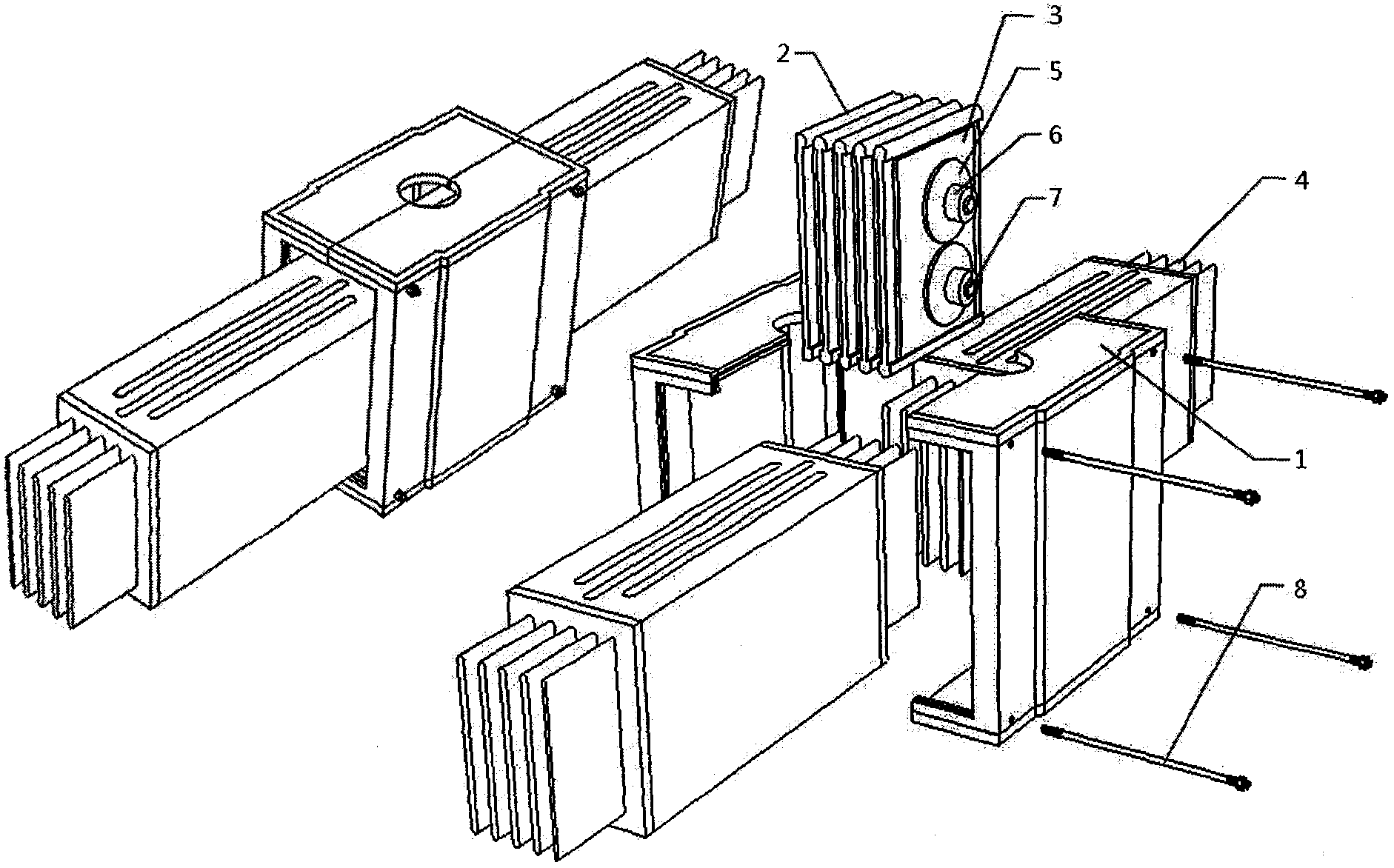

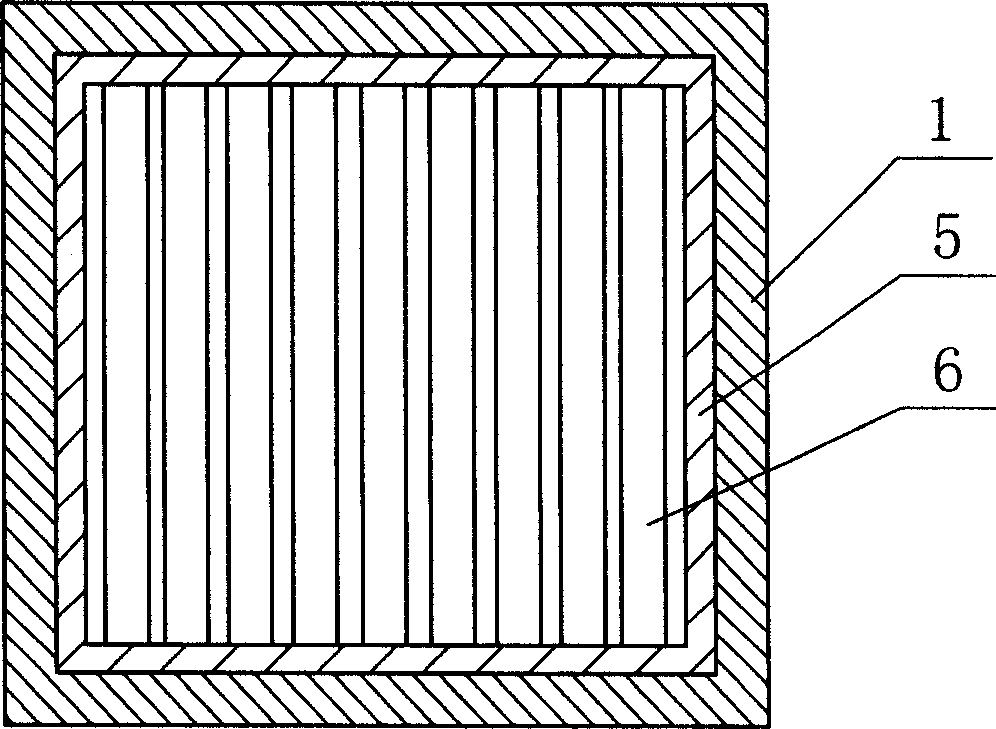

Fireproof poured bus way

The invention relates to a fireproof poured bus way which is capable of overcoming the shortages that a low-voltage power transmission and distribution bus way main line system can not be used outdoors and in the environment with corrosion pollution. The fireproof poured bus way can be safely operated for a certain time under the state of a fire disaster. According to the fireproof poured bus way, the method of 'processing technology of pressure injection gel forming epoxy poured bus way' (patent application number: 201220081075.3) is adopted, fireproof agent, filling agent and curing agent are added into inflaming retarding epoxy resin, wherein the fireproof agent, the filling agent and the curing agent are in an appropriate matching ratio, the fireproof agent, the filling agent, the curing agent and the inflaming retarding epoxy resin are stirred in a vacuum stirring machine when the vacuum stirring machine is vacuum-pumped, the completely mixed mixture is injected into a pre-heated steel die through pressure, so that thermal-curing gel forming is conducted, and fireproof poured bus units are formed. After the fireproof poured bus units are firmly connected through mica insulation joint connectors researched and developed by this company according to the engineering design requirements, the fireproof poured bus units are sleeved with a 'connecting box for poured bus way' (patent application number: ZL 201020104497.9), and a fireproof pouring mixed material is poured along a pouring notch of the connecting box so that the whole fireproof poured bus way can be cured.

Owner:上海精成电器成套有限公司

Voltage-resistant, arc-resistant and high-impact-resistant PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) alloy as well as preparing method and application thereof

The invention discloses a voltage-resistant, arc-resistant and high-impact-resistant PC (Polycarbonate) / ABS (Acrylonitrile Butadiene Styrene) alloy. The PC / ABS alloy consists of an antioxidant B900, an ultraviolet absorbent UV329, a flexibilizer, a fire retardant HT-202M, an insulating agent 1, an insulating agent 2, ABS and PC. The voltage-resistant, arc-resistant and high-impact-resistant PC / ABS alloy has the excellent insulating properties of high impact resistance, wear resistance, high-voltage resistance, arc resistance and the like. The high-voltage resistance property of the product reaches 40MV / m, the arc resistance property reaches 535MV / m, and the surface resistivity is as high as 1019 ohm.m. The product cannot be easily broken down by high voltage and has excellent insulating properties. The voltage-resistant, arc-resistant and high impact-resistant PC / ABS alloy is particularly suitable for being applied to the manufacture of instrument and apparatus casings, aerospace vehicle interior trimmings, automobile interior trimmings, ship interior trimmings, electric appliance casings, exercise instruments and medical instruments.

Owner:林湖彬

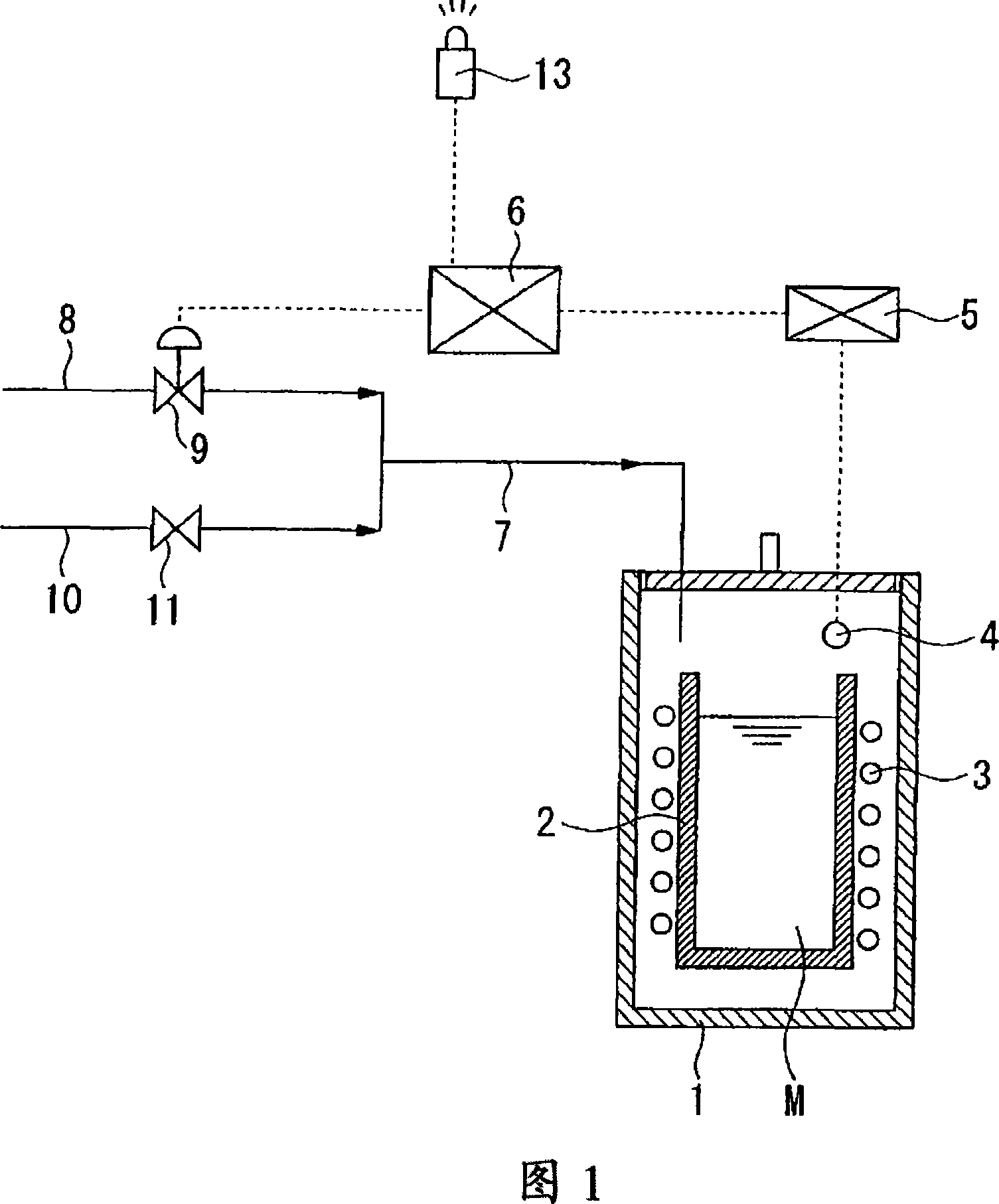

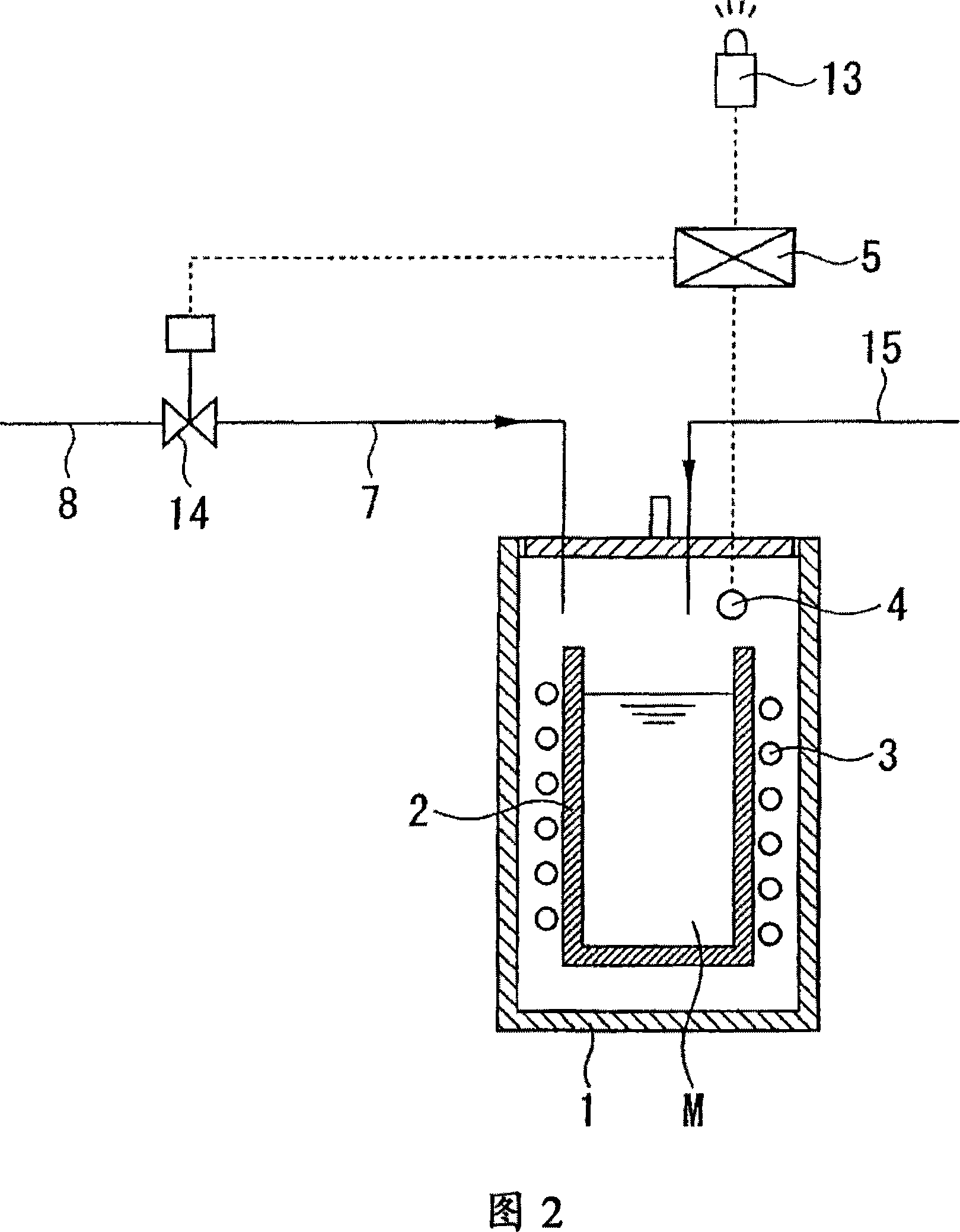

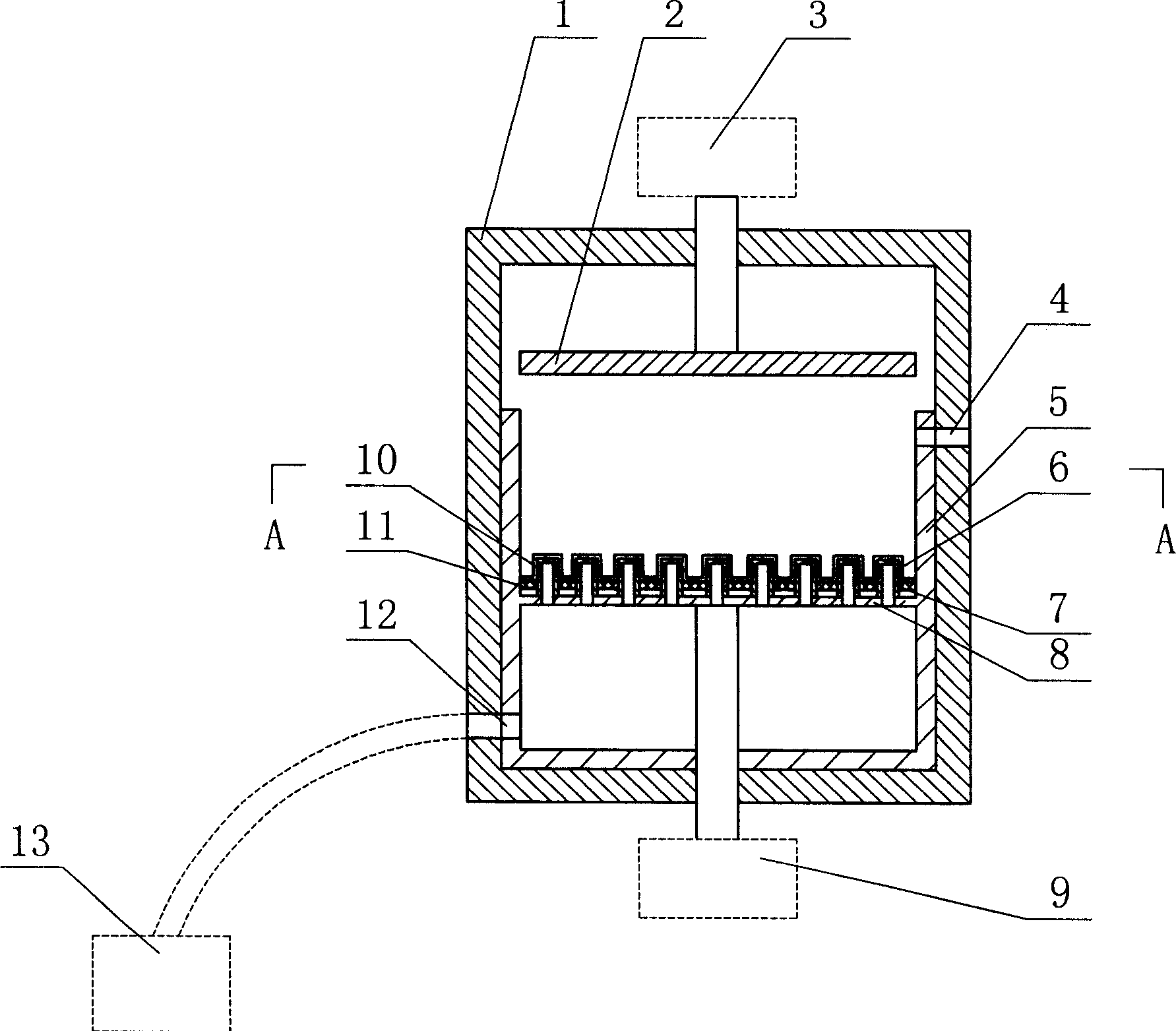

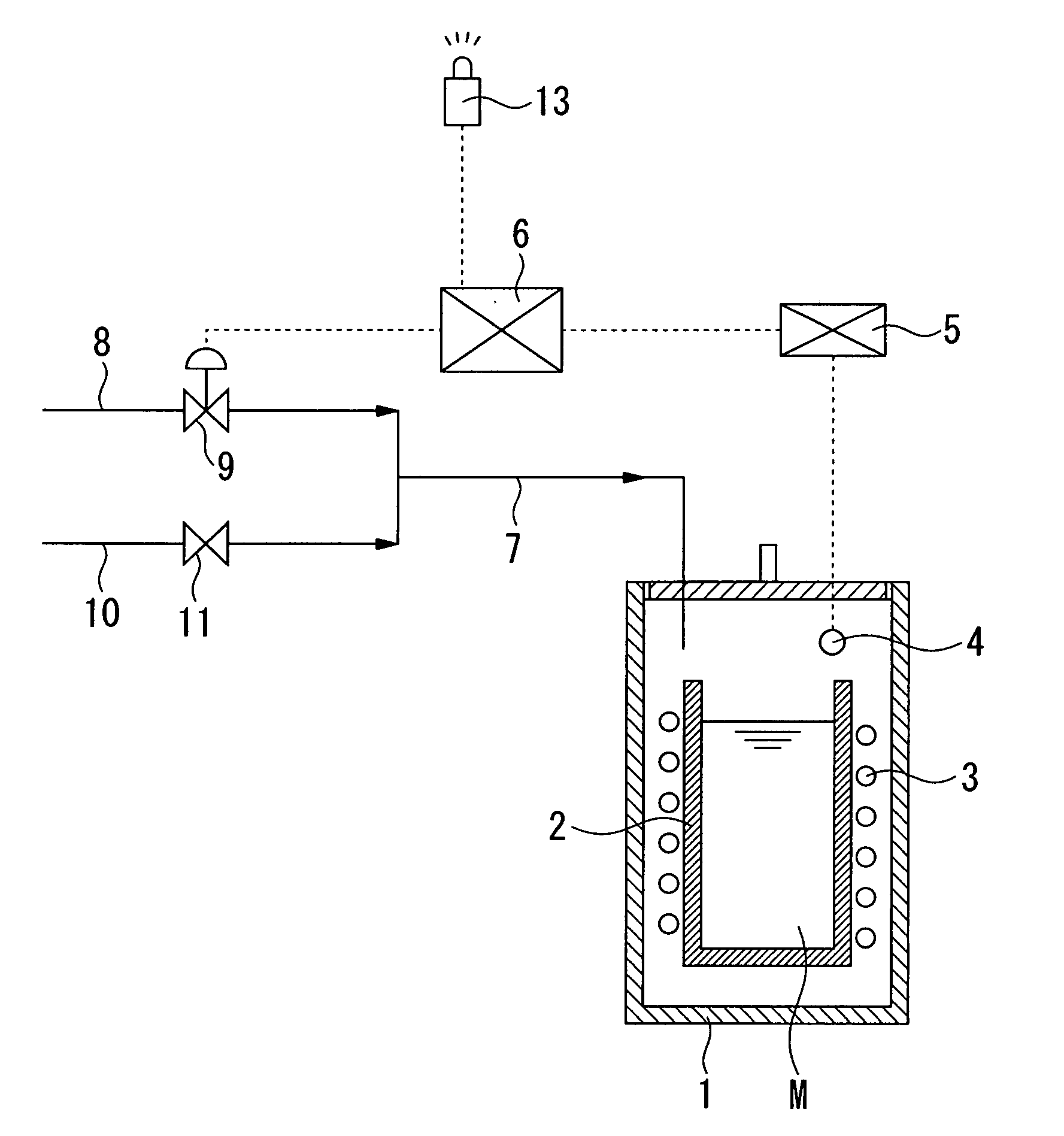

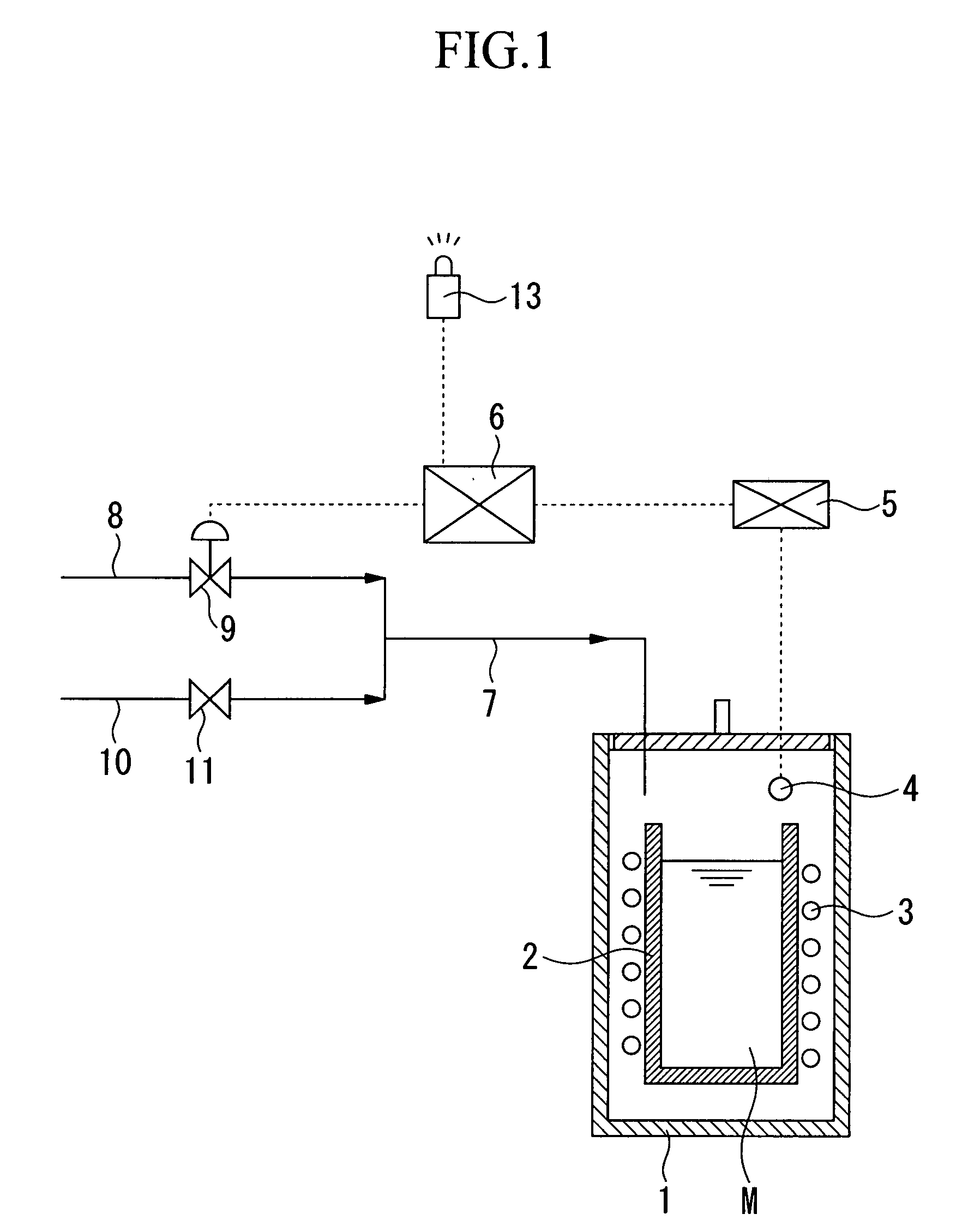

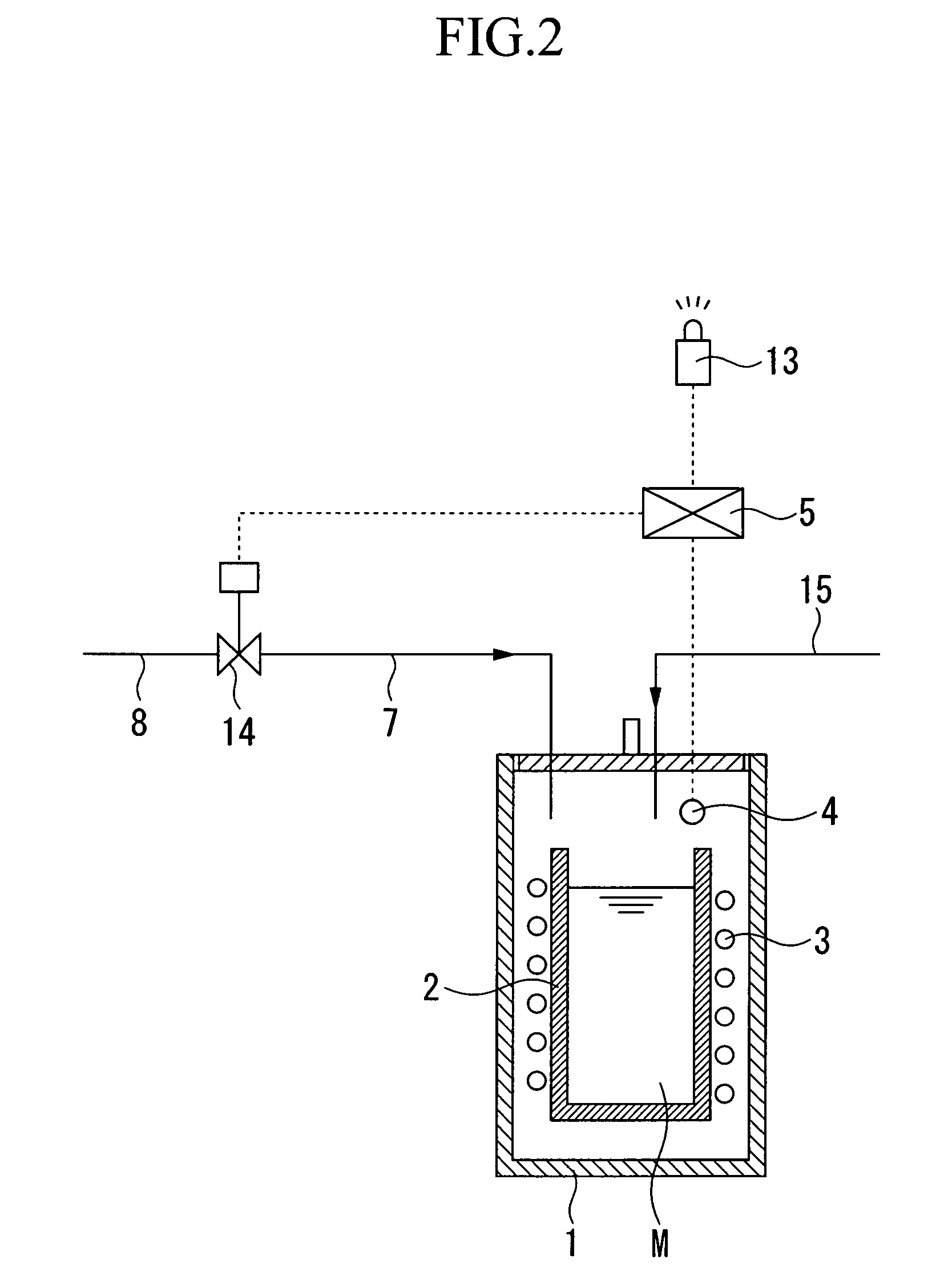

Method of melting magnesium and melting apparatus

InactiveCN101107370AProtection automatic controlFully automatedIncreasing energy efficiencyCombustionShielding gas

Owner:NIPPON SANSO CORP +1

Fire, weather and high temperature resistant polyvinyl chloride tube and production method thereof

The invention discloses a fire, weather and high temperature resistant polyvinyl chloride tube and a production method thereof. The fire, weather and high temperature resistant polyvinyl chloride tube comprises, by mass, 55-78% of polyvinyl chloride, 6-12% of carbon fiber, 5-8% of a plasticizer, 3-6% of PETG, 2-5% of ACR, 2-4% of a fireproof agent, 1-3% of nanometer titanium dioxide, 1-2% of an antistatic agent HKD-912, 0.5-2% of an anti-ultraviolet absorbent UV-326, 0.5-1.5% of a calcium and zinc composite stabilizer, 0.5-1% of zinc stearate and 0.1-0.5% of an antioxidant. The fire, weather and high temperature resistant polyvinyl chloride tube has the advantages of strength increase, weather resistance, fire resistance, high temperature resistance, antistatic property, good mechanical properties, high strength, good processability, low cost, simple preparation process and wide adaptation range.

Owner:殷培花

Straw fireproofing and heat-insulating board and production method thereof

InactiveCN104724976AReduce manufacturing costImprove filling abilitySolid waste managementFiberFireproofing

The invention discloses a straw fireproofing and heat-insulating board and a production method thereof, belonging to the technical field of buildings. The straw fireproofing and heat-insulating board consists of the following raw materials: 20-40 parts of phenolic resin particles, 40-80 parts of straw, 1-5 parts of latex powder, 5-10 parts of a fireproofing agent, 1-5 parts of water repellent, 0.1-1 part of a surfactant and 100-200 parts of water. The invention also provides a production method of the straw fireproofing and heat-insulating board, wherein the production method comprises the steps of mixing the raw materials, uniformly stirring, putting the mixed raw materials in a mold, demolding and aging. According to the straw fireproofing and heat-insulating board and the production method thereof disclosed by the invention, straw is taken as a main filling material to produce the heat-insulating board which is strong in capacity of resisting bending, pressure and fracture, high in fireproofing grade, convenient in construction and low in cost on the basis of the full utilization of the characteristics of the straw which is strong in filling capacity, high in fiber toughness and strong in fireproofing and heat-insulating capacities under the functions of the phenolic resin particles, the latex powder and the water repellent; and meanwhile, the problems on post-treatment and recycling of agricultural waste are solved.

Owner:昆山文创建筑装饰工程有限公司

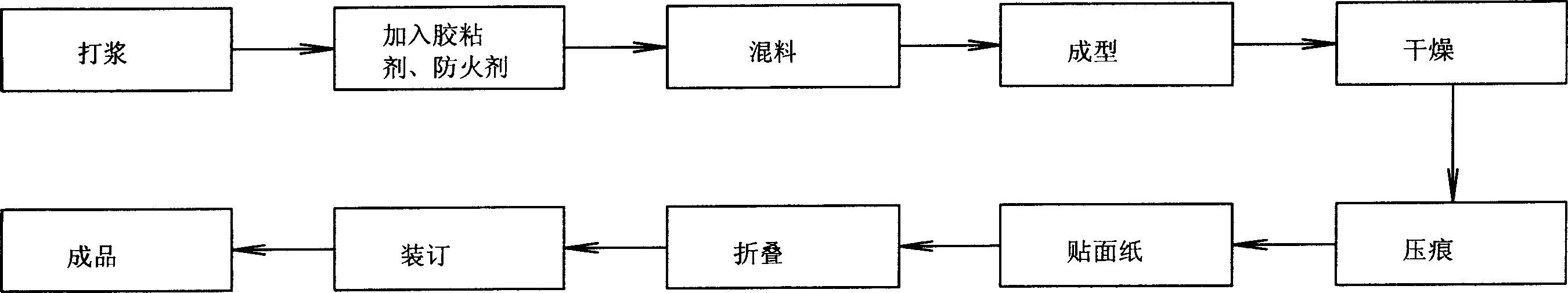

Manufacturing method of cellular carton and forming device thereof

InactiveCN1831245AHard textureHigh strengthTextiles and paperContainer making machineryProduction ratePlant fibre

The invention is a method for making cellular carton, crushing plant fibers into pulp, adding in adhesive and fireproof agent; pouring the pulp into a moulding box, pressurizing, dehydrating and moulding to make wet board blank; feeding the wet board blank into a drying chamber for drying; bonding paper onto the dry paperboard; according to the shape and size of a cellular carton to be moulded, cutting the dry paperboard, and then binding and making the cellular carton. And a moulding device implementing the method comprises an oil hydraulic press frame, where a moulding box is arranged in the frame, lower and upper moulding plates are installed in the moulding box, a blind pipe is arranged on the lower moulding plate and a splint is arranged above the lower moulding plate, the lower surface of the upper moulding plate is a plane, a pulp pouring hole is arranged on the top of the side wall of the moulding box and a water outlet hole is arranged at the bottom of the moulding box. And the advantages: wide source of raw materials, such as waste paper, pulp residues, and stalks; able to use waste materials; able to reduce environmental pollution; the producing method is simple, high-efficiency and low-cost.

Owner:赵立

Fibrous reinforcement suitable as a fireproofing agent

ActiveUS7045203B2Easy to produceFibre treatmentSynthetic resin layered productsFireproofingGlass transition

A fibrous reinforcement including a fibrous support treated throughout or covered at least partially on one of its surfaces with a compound containing: i) one or more thermosetting prepolymers having a softening temperature of 150° C. or lower and / or one or more thermoplastic polymers having a glass transition temperature lower than 300° C.; and ii) one or more inorganic phosphorus compounds. The treatment ratio of the fibrous support with the inorganic phosphorus compound(s) falls within the range of 2%–20% by weight. The fibrous reinforcement is suitable for use as a fireproofing agent.

Owner:HEXCEL REINFORCEMENTS SAS

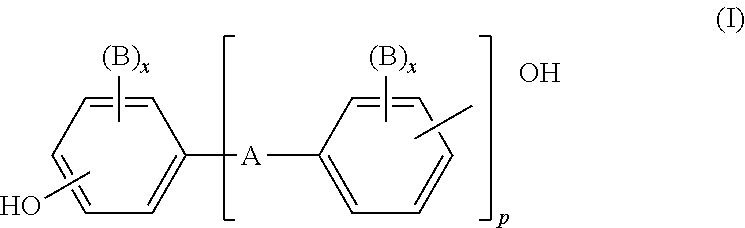

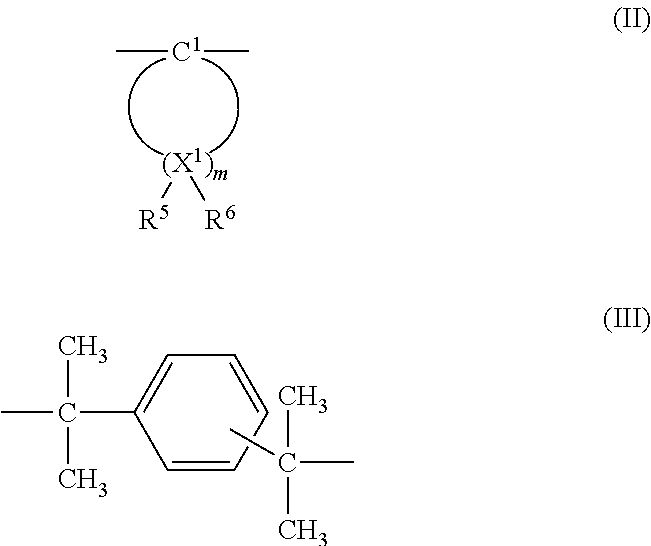

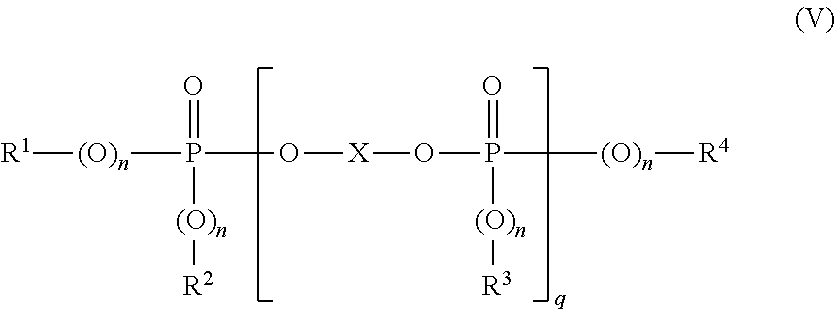

Easy-flowing polycarbonate/abs moulding compositions with good mechanical properties and a good surface

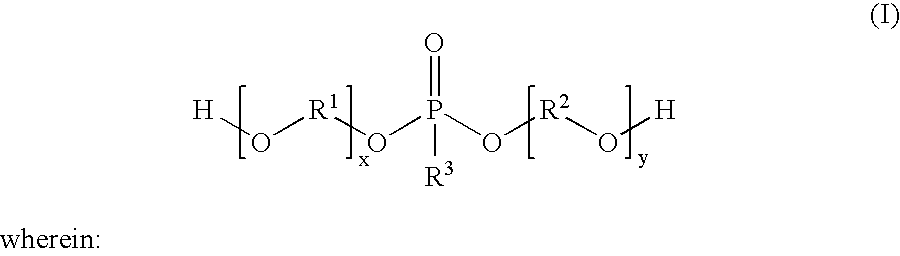

ActiveUS20110263766A1Improve mechanical propertiesGood and trouble-free surfacePhosphorus organic compoundsFree formInjection moulding

The present invention relates to flame-resistant moulding compositions of polycarbonates and graft polymers which, in addition to good flow properties, have very good mechanical properties and a particularly good, trouble-free surface. These moulding compositions are suitable in particular for injection moulding uses for mouldings with thin wall thicknesses and high-gloss surfaces. The thermoplastic moulding compositions according to the invention comprise A) 65.0 to 82.0 parts by wt. of at least one aromatic polycarbonate, B) 4.0 to 11.0 parts by wt. of at least one graft polymer, C) 14.0 to 24.0 parts by wt. of at least one phosphorus-containing flameproofing agent, wherein the sum of the parts by weight of components A to C adds up to 100 parts by weight and the total content of the polymer which is formed from the grafting monomers or is added in the free form and is not bonded chemically to the graft base is less than 2.0 wt. %, based on the total moulding composition.

Owner:COVESTRO DEUTSCHLAND AG

Modified polyurethane heat insulation board and production method thereof

The invention discloses a modified polyurethane heat insulation board and a production method thereof, and belongs to the technical field of building materials. Raw materials for preparing the modified polyurethane heat insulation board comprise 80-120 parts of a polyurethane particle, 10-30 parts of resin adhesive powder, 10-30 parts of a foaming agent, 30-60 parts of a fire retardant and 1-5 parts of a film forming assistant, wherein the fire retardant is composed of 3-10% of zinc borate, 20-30% of magnesium oxide, 30-40% of magnesium chloride, 10-20% of silicon powder, 1-10% of diatomite, and the balance of water. The invention also provides a production method of the modified polyurethane heat insulation board. The polyurethane heat insulation board is formed through rolling, molding and decorative board laying of waste polyurethane particles under the action of the resin adhesive powder, the foaming agent, the fire retardant and the film forming assistant. The production method has the advantages of simple technology, less investment and low cost, and the polyurethane heat insulation board has the advantages of good heat insulation performances, high fireproof grade, safe use and wide application range.

Owner:昆山文创建筑装饰工程有限公司

Refined anti-flaming compounding agent and preparation method thereof

The present invention belongs to the field of metal material, and is one kind of refined composite fireproof agent for casting Mg-Al alloy. The refined composite fireproof agent has the chemical components including RECO3 5-30 wt%, MgCO3 5-30 wt%, La2(CO3)3 5-30 wt%, MgCl 2 5-30 wt%, NaCl 5-30 wt%, KCl 5-30 wt%, BaCl2 0-5 wt%, CaF2 3-5 wt% and Al2O3 0.8-1.8 wt%. The refined composite fireproof agent has both Mg-Al alloy refining and fireproofing effect, contains no toxic matter or element, has good refining effect, covering function and small water absorbing amount, and can improve the mechanical performance of Mg-Al alloy obviously.

Owner:TAIYUAN UNIV OF TECH

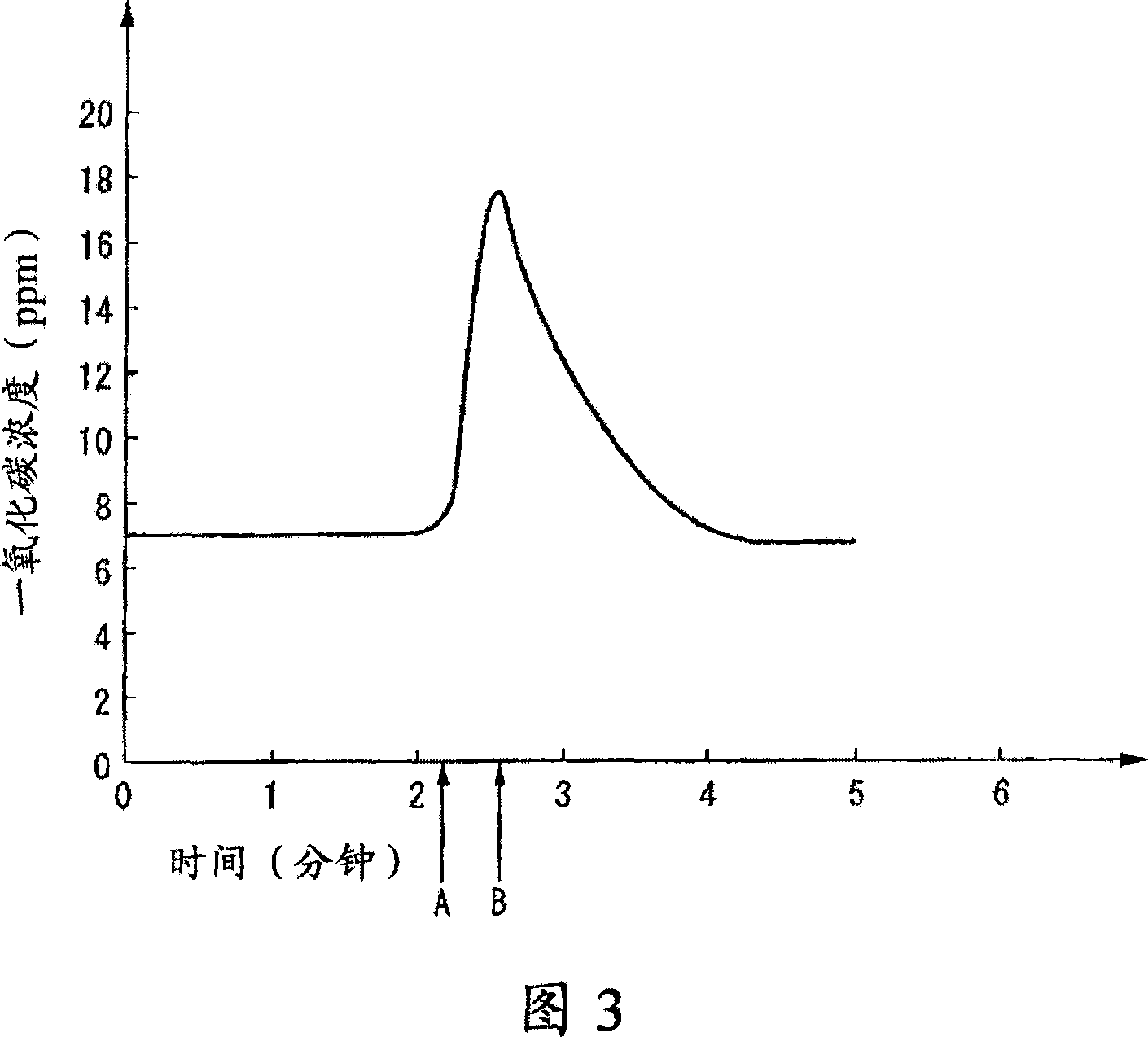

Method for Melting Magnesium and Melting Apparatus

InactiveUS20070295166A1Blast furnace detailsIncreasing energy efficiencyCombustionFireproofing Agents

An object of the present invention is to provide a melting method for magnesium or a magnesium alloy which detects certainly and immediately combustion of a magnesium melt and emits alarm immediately based on the detection results, and extinguishes immediately the magnesium combustion, in order to achieve the object, the present invention provide a method for melting magnesium while supplying a cover gas containing carbon dioxide and a fireproof agent in a furnace for melting magnesium and obtaining a magnesium melt to cover the surface of the magnesium melt, wherein concentration of carbon monoxide in the furnace or gas discharged from the furnace is measured and magnesium combustion in the furnace is detected based on the concentration of carbon monoxide.

Owner:NIPPON SANSO CORP +1

Preparation method of damp-proof flame-retardant corrugated paper case

InactiveCN109518535AImprove moisture resistanceImprove flame retardant propertiesFlexible coversWrappersPulp and paper industryChlorinated paraffins

The invention discloses a preparation method of a damp-proof flame-retardant corrugated paper case. The outer side surface and inner wall surface of the corrugated paper case are uniformly coated withdamp-proof flame-retardant coating layers. The damp-proof flame-retardant coating layers contains a resin mixture, an ethanol water solution, a grease product, chlorinated paraffin, a damp-proof agent, a fireproof agent and a compound stabilizer. The preparation method particularly comprises the following steps: (1) mixing the ethanol water solution with the grease product and chlorinated paraffin, and carrying out ultrasonic high-speed dispersion; (2) adding the damp-proof agent, the fireproof agent and the compound stabilizer, and carrying out ultrasonic high-speed dispersion; (3) finally adding the resin mixture, carrying out ultrasonic high-speed dispersion, and uniformly mixing, so as to obtain the damp-proof flame-retardant coating layers; and (4) spraying the damp-proof flame-retardant coating layers to the outer side surface and inner wall surface of the corrugated paper case. The corrugated paper case with relatively good damp-proof property and flame retardance is prepared from the common raw material components by virtue of a simple and easily-operated method and is low in production cost and high in product benefit.

Owner:南京志超汽车零部件有限公司

Method for preparing mixed plastic-wood floor material

The invention discloses a method for preparing a mixed plastic-wood floor material. The method comprises the following steps: weighing an inorganic nonmetal material, wood flour, PE particles, a compatilizer, a lubricant, an antioxidant, an ultraviolet ray absorber, a light stabilizer, a heat stabilizer, a mildew preventive, an insect-resist agent and a fire-proofing agent; mixing the PE particles, the lubricant, the antioxidant, the ultraviolet ray absorber, the light stabilizer, the heat stabilizer, the mildew preventive, the insect-resist agent and the fire-proofing agent for 4-8min in a mixer, then adding 58-72% of inorganic nonmetal material and evenly mixing; adding the wood flour and the compatilizer and evenly mixing; adding residual inorganic nonmetal material and fully agitating for 10-13 minutes; palletizing, drying and feeding in an extruder for extruding and molding; cooling and sanding to obtain the mixed plastic wood-floor material. The mixed plastic-wood floor material has high shock strength and excellent anti-pressure ability, and the deformation resistance of the floor material is obviously improved.

Owner:安徽惠云塑木股份有限公司

Fire retardant coating

ActiveCN103242721AImprove fire performanceBroaden applicationFireproof paintsPhosphoric Acid EstersCellulose

The invention belongs to the technical field of coating, and particularly relates to fire retardant coating, which is characterized in that the fire retardant coating comprises the following raw materials in parts by weight: 10-15 parts of carboxyethyl cellulose aqueous solution, 15-18 parts of polyvinyl acetate emulsion, 18-25 parts of tris(2-chloroethyl)-phosphate, 0.5-1.5 parts of OP-10 type emulsifier, 13-20 parts of talcum powder, 13-16 parts of titanium dioxide, 0.5-1.5 parts of potassium tripolyphosphate, 0.5-1.5 parts of mica powder with the fineness smaller than 200 meshes, 1-3 parts of boric acid, 2.5-3.5 parts of fire retardant, 6-10 parts of distilled water, 1-3 parts of magnesium hydroxide, 1-3 parts of silicone oil and 1-3 parts of dioctyl phthalate. The fire retardant coating has the beneficial effects of good fire retardant property, convenience in manufacturing, simple manufacturing method, less equipment investment and convenience in coating and is also applied to machine spraying.

Owner:BEIJING KEYING JINGYI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com