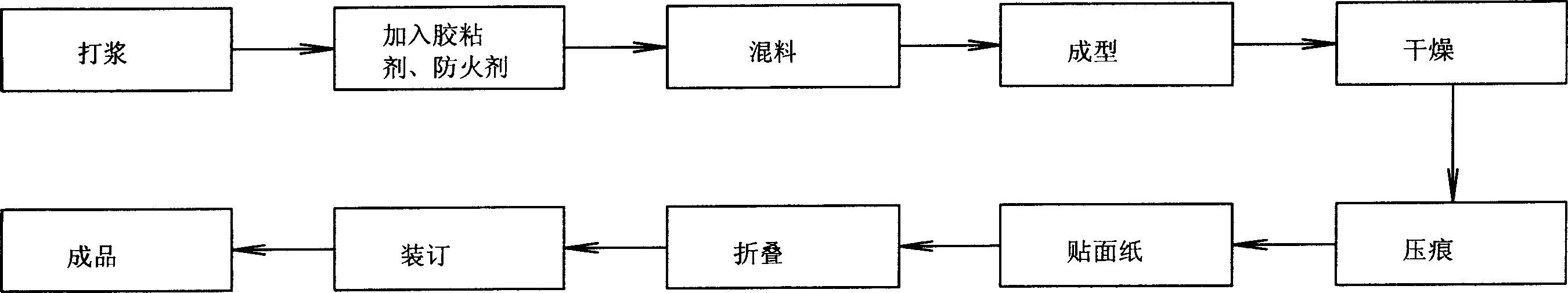

Manufacturing method of cellular carton and forming device thereof

A technology of honeycomb paperboard and forming device, which is applied to paper/cardboard containers, container manufacturing machinery, packaging, etc., can solve the problems of complex production process, low degree of mechanization, and high manufacturing cost, and achieves reduction of environmental pollution, simple production method, and high cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

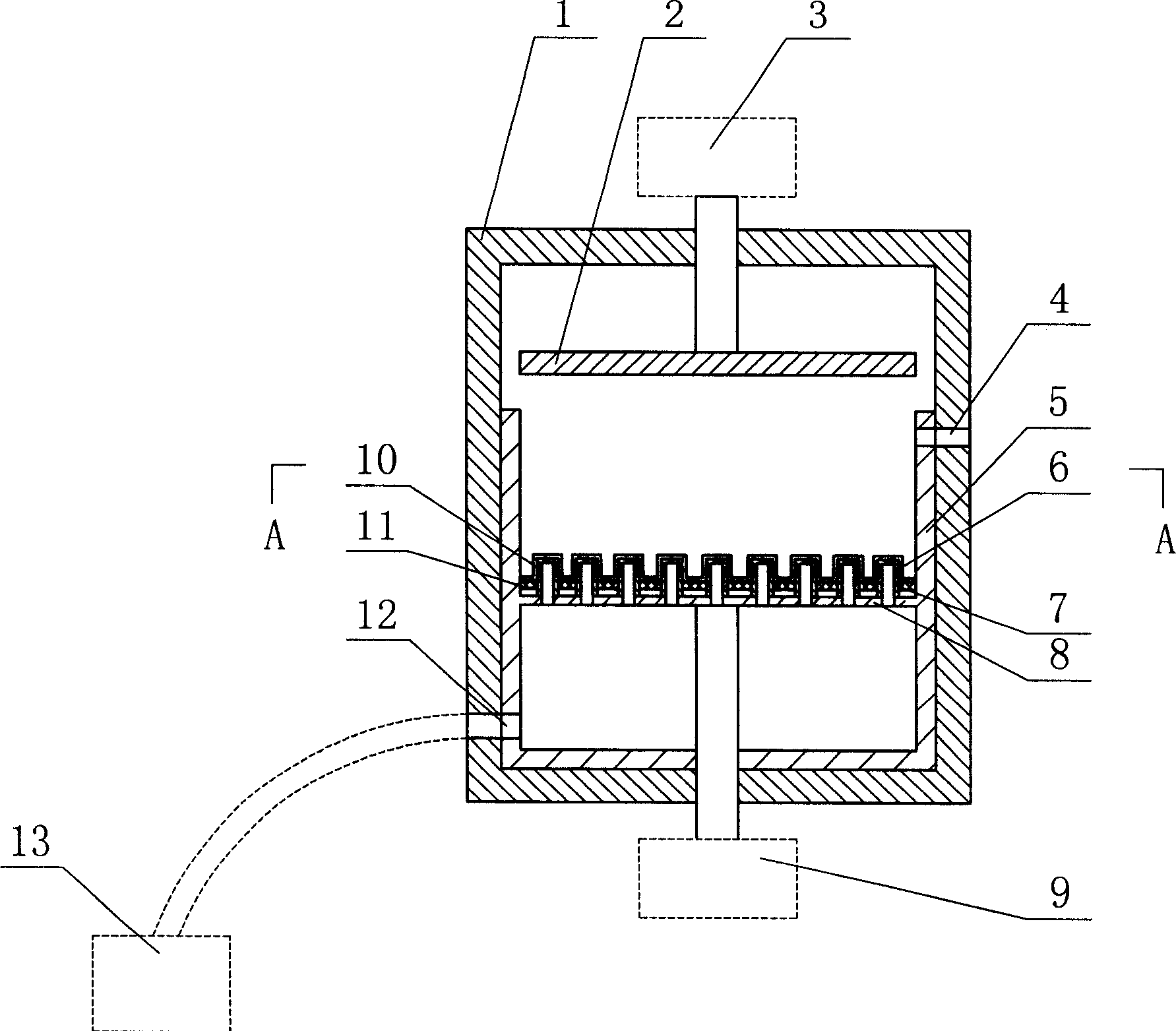

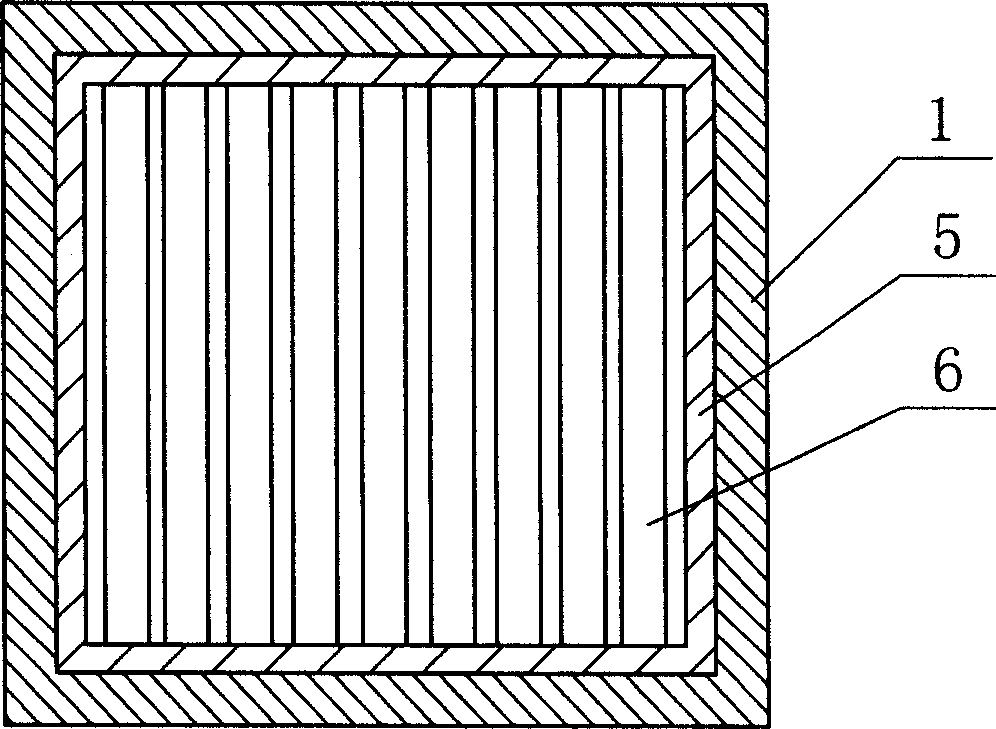

[0015] As shown in the figure, the present invention has a hydraulic press frame 1, on which the hydraulic press is fixed, and a forming box 5 is installed in the hydraulic press frame 1, and a protrusion is provided on the side wall of the forming box 5, the said forming box 5 The upper part of the side wall is provided with a slurry inlet 4, and an upper mold pressing plate 2 and a lower mold pressing plate 8 are installed in the forming box 5. Drive up and down. Said lower mold pressing plate 8 is fixed in the forming box 5, and a blind pipe 7 is welded on the upper surface of the lower mold pressing plate 8, and the upper end (sealing end) of said blind pipe 7 is provided with a water seepage hole 10, corresponding to the lower mold pressing plate 8. The lower end of the blind pipe 7 has a water outlet, and a gauze 6 is sheathed outside the blind pipe 7 to prevent the paper pulp from blocking the water seepage hole when forming. A supporting plate 11 is installed above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com