Normal-temperature processed cheese and preparation method thereof

A technology for processed cheese at normal temperature, which is applied in the field of processed cheese at normal temperature and its preparation. It can solve problems such as unstable quality, easy oil and water separation, and granulated texture, and achieve a good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

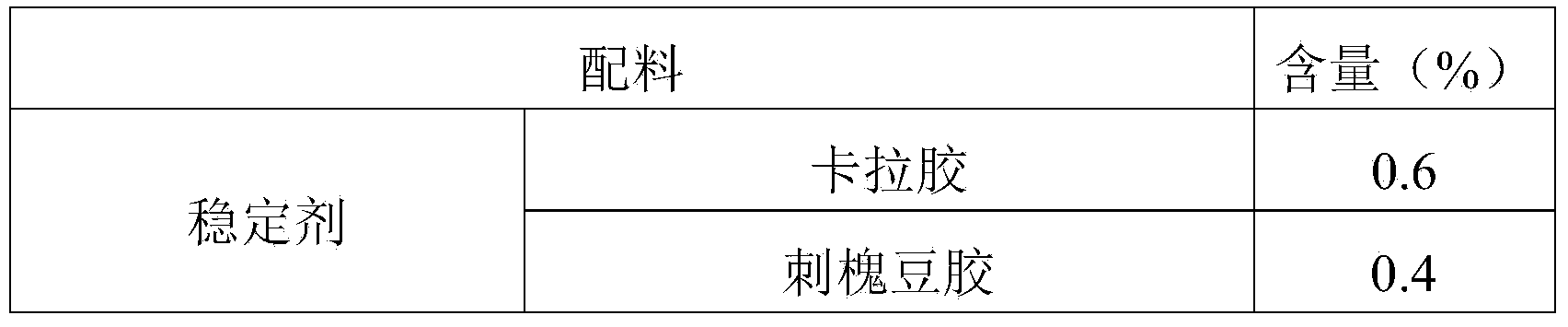

[0048] Table 1 The raw material formula of the room temperature processed cheese of Example 1

[0049]

[0050]

[0051] The preparation method is as follows:

[0052] (1) Pre-mix the stabilizer, flavoring agent and emulsifier uniformly;

[0053] (2) Stir the mixture of step (1) into 50% water, stir and heat at 60°C until the material is uniform;

[0054] (3) Add natural cheese, emulsifying salt, and the remaining 50% water into the melting pot, heat to 50°C, 700RPM and stir until the cheese melts;

[0055] (4) Pour the solution obtained in step (2) into the melting pot in step (3), stir at 700RPM and raise the temperature to 90°C, keep it warm and sterilize for 8min;

[0056] (5) Homogenization, the first stage pressure is 150bar, the second stage pressure is 50bar, and the homogenization temperature is 88℃;

[0057] (6) Pouring and cooling to 2°C to form;

[0058] (7) The processed cheese obtained in step (6) is vacuum dried at 0°C, and the moisture content reaches 20%, and then packed w...

Embodiment 2

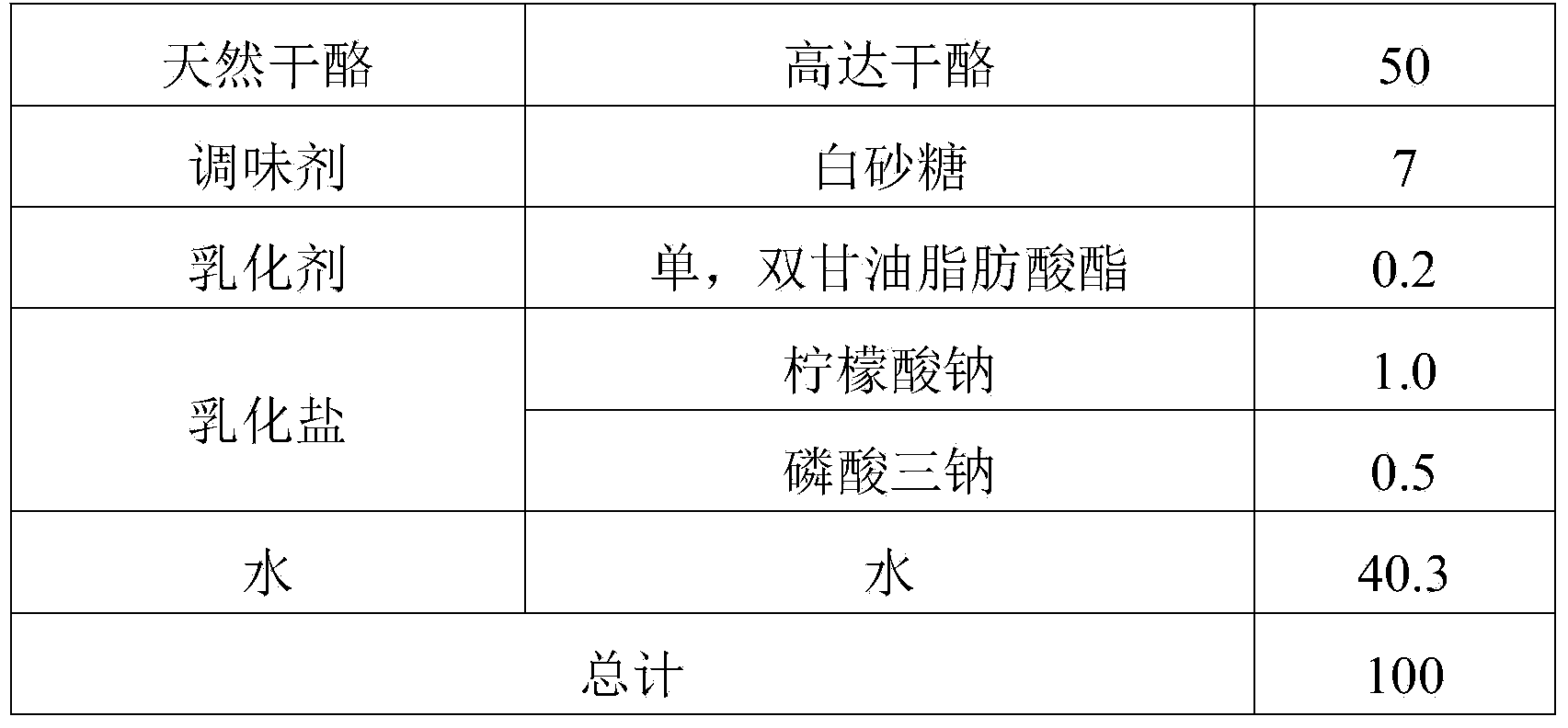

[0060] Table 2 The raw material formula of the room temperature processed cheese of Example 2

[0061]

[0062]

[0063] Preparation:

[0064] (1) Mix the stabilizer, emulsifier and preservative in a vertical mixer evenly;

[0065] (2) Stir the mixture of step (1) into 40% water, stir and heat at 80°C until the material is uniform;

[0066] (3) Add natural cheese, emulsifying salt, and the remaining 60% water into the melting pot, heat to 60°C, 600RPM, and stir until the cheese melts;

[0067] (4) Pour the solution obtained in step (2) into the melting pot in step (3), stir and heat up to 95°C at 600RPM, and keep the temperature for 5 minutes for sterilization;

[0068] (5) Homogenization, the first-stage pressure is 160bar, the second-stage pressure is 40bar, and the homogenization temperature is 95℃;

[0069] (6) Pouring and cooling to 10°C to form;

[0070] (7) The processed cheese obtained in step (6) is vacuum dried at 10°C, and the moisture content reaches 12%, and then it is packed ...

Embodiment 3

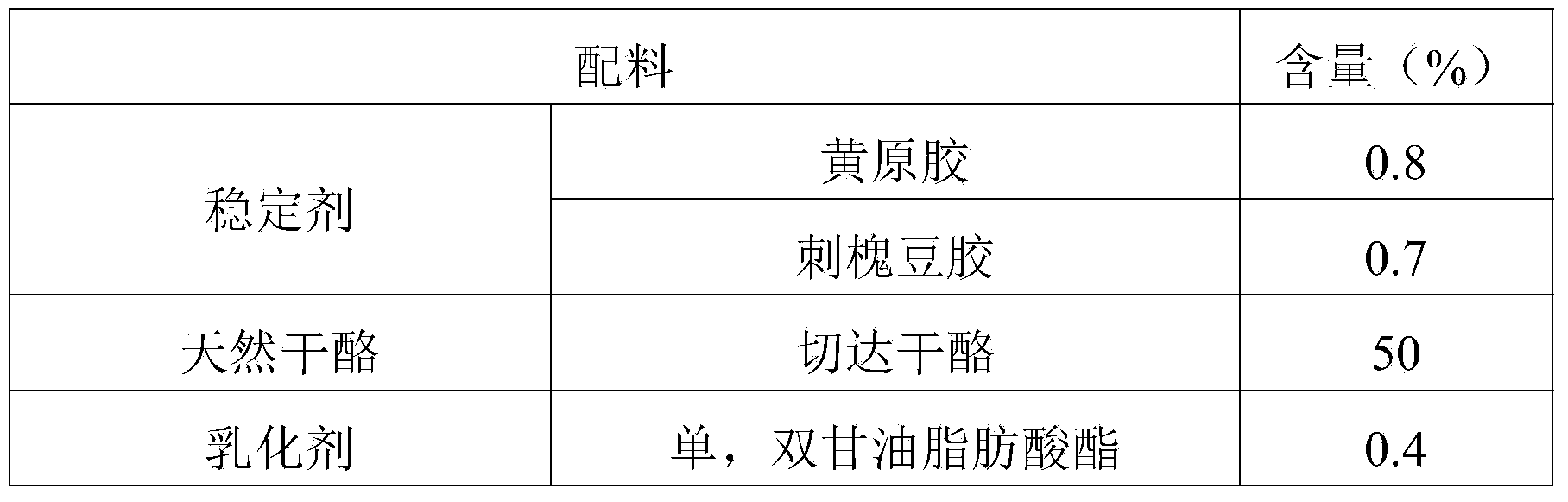

[0072] Table 3 The raw material formula of the room temperature processed cheese of Example 3

[0073]

[0074]

[0075] Preparation:

[0076] (1) Pre-mix stabilizers, flavoring agents, emulsifiers and preservatives uniformly;

[0077] (2) Stir the mixture of step (1) into 60% water, stir and heat at 90°C until the material is uniform;

[0078] (3) Add cheese, emulsifying salt, acidity regulator, and the remaining 40% water to the melting pot, heat to 70℃, 800RPM and stir until the cheese melts;

[0079] (4) Pour the solution obtained in step (2) into the melting pot in step (3), stir and heat up to 92°C at 800RPM, and keep it warm for 6min;

[0080] (5) Homogenization, the first-stage pressure is 150bar, the second-stage pressure is 50bar, and the homogenization temperature is 90℃;

[0081] (6) Pouring and cooling to 20℃ to form;

[0082] (7) Put the processed cheese obtained in step (6) in a 30°C oven, and vacuum package after the moisture reaches 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com