Cold resistant polycarbonate/ABS alloy for intelligent ammeter shell and preparation method thereof

A technology of polycarbonate and smart meters, applied in the direction of measuring electrical variables, instruments, measuring devices, etc., can solve the problems of poor cold resistance, poor cold resistance of PC/ABS, etc., and achieve high cold resistance, high material stability and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A polycarbonate / ABS alloy for a cold-resistant smart meter casing of the present embodiment, its raw material formula is composed of the following components in parts by weight:

[0057] PC 25 copies;

[0058] 33 parts of PC recycled materials;

[0059] ABS recycled material 20 parts;

[0060] 9 copies of MBS;

[0061] 5 parts of triphenyl phosphate;

[0062] 0.5 parts of FR2025 fire retardant;

[0063] 1 part of titanium dioxide;

[0064] Antioxidant 1010 0.5 parts;

[0065] Antioxidant 168 0.3 parts;

[0066] Anti-ultraviolet agent UV-531 0.5 parts;

[0067] Diffusion powder EBS 0.08 parts;

[0068] 0.06 parts of ultramarine blue powder;

[0069] 0.04 parts of iron oxide red powder;

[0070] High temperature resistant fluorescent yellow powder 0.01 parts;

[0071] 5 parts cold resistance agent;

[0072] The above-mentioned cold-resistant agent is cold-resistant agent 2602 produced by Rohm and Haas Company of the United States, and its full English name is ...

Embodiment 2

[0079] A polycarbonate / ABS alloy for a cold-resistant smart meter casing of the present embodiment, its raw material formula is composed of the following components in parts by weight:

[0080] PC 35 copies;

[0081] PC recycled material 20 parts;

[0082] ABS recycled material 25 parts;

[0083] 6 copies of MBS;

[0084] 7 parts of triphenyl phosphate;

[0085] 0.3 parts of FR2025 fire retardant;

[0086] 2 parts of titanium dioxide;

[0087] Antioxidant 1010 0.5 parts;

[0088] Antioxidant 168 0.5 part;

[0089] Anti-ultraviolet agent UV-531 0.5 parts;

[0090] Diffusion powder EBS 0.08 parts;

[0091] 0.06 parts of ultramarine blue powder;

[0092] 0.03 parts of iron oxide red powder;

[0093] High temperature resistant fluorescent yellow powder 0.01 parts;

[0094] 4 parts cold resistance agent;

[0095] The above-mentioned cold-resistant agent is cold-resistant agent 2602 produced by Rohm and Haas Company of the United States, and its full English name is PARA...

Embodiment 3

[0102]In the polycarbonate / ABS alloy for the cold-resistant smart meter casing of this embodiment, except that the cold-resistant agent in the raw material formula is cold-resistant agent M721 (a kind of cold-resistant agent commonly used), the components of the other raw material formulas, and the alloy The preparation methods are all the same as in Example 2.

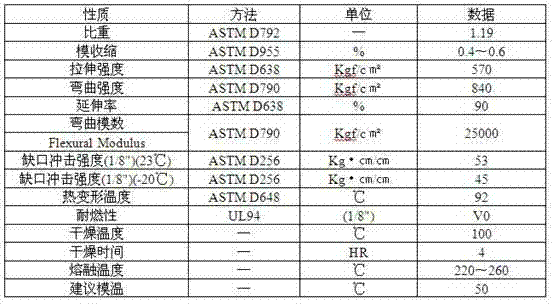

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com