Method for producing anti-static flame retardant, water-proof and oil-proof natural fibrous fabric

A technology of natural fibers and manufacturing methods, applied in fabrics, fiber processing, textiles and papermaking, etc., can solve the problems of expensive, single safety and health performance protection, difficult to apply to ordinary labor protective clothing and military equipment clothing, etc. , to achieve the effect of expanding new fields and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

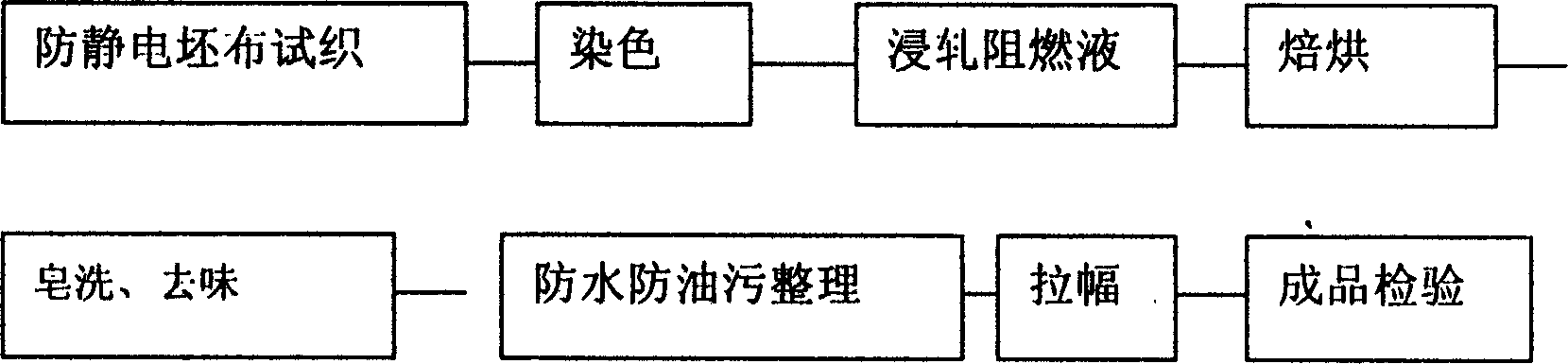

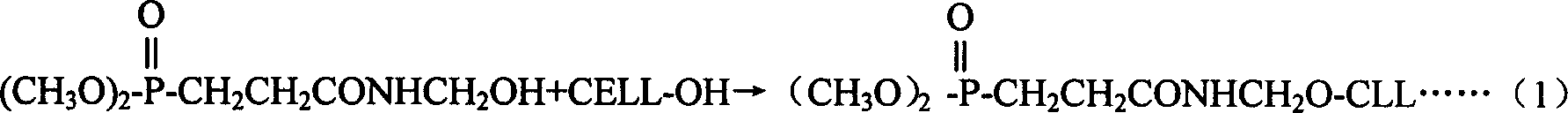

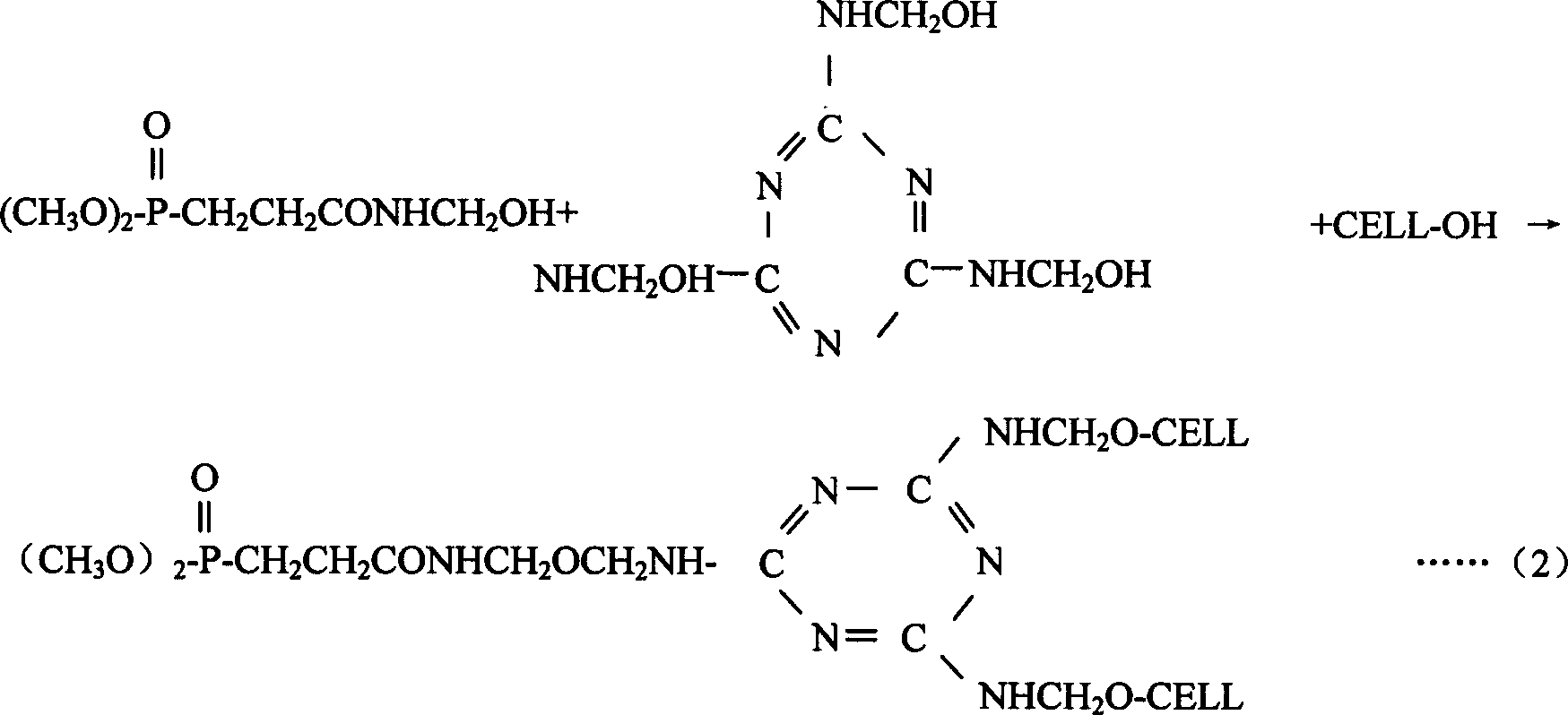

Method used

Image

Examples

Embodiment Construction

[0027] The antistatic method of the natural fiber fabric of the present invention uses organic conductive fibers or metal conductive fibers (or stainless steel fibers) to weave organic conductive fibers or metal conductive fibers (or blends) at equal intervals in the warp or weft direction of the fabric during textile processing. Into stainless steel fiber). The natural fiber fabric of the present invention includes all cotton, wool, hemp or viscose fibers, and also includes fabrics with a blended synthetic fiber content of not more than 10%, and of course also includes a blended fabric of natural fibers.

[0028] The characteristics of the anti-static fabric used in the present invention are: good anti-static durability (withstands washing more than 100 times); the amount of positive conductive fiber can also be adjusted to meet the different requirements of different products for anti-static performance; Dyeing coverage (colorless conductive yarn can be dyed) is better, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com