Dyeing method after flame-retardant for all-cotton fabric

A technology for cotton fabrics and fabrics, applied in dyeing, plant fibers, textiles and papermaking, etc., which can solve the problems of discounted appearance of flame-retardant cotton fabrics, lightening and darkening of fabric colors, and damage to dyes, etc., to achieve soft hand feeling and bright colors , the effect of color quality improvement

Inactive Publication Date: 2010-11-10

南通东升艾克特种纺织防护面料有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current flame-retardant finishing technology is mainly divided into Proban (UK) and Pyrovetexcp. Although they are relatively mature flame-retardant finishing processes, there are still many defects and deficiencies in the production process.

Both Proban and Pyrovetexcp will produce formaldehyde and other by-products in the production process. These two processes have a destructive effect on dyes and a strong decolorization effect on dyes. After flame-retardant finishing, the color of the fabric changes greatly. The color becomes lighter and darker, resulting in a greatly reduced appearance of flame-retardant cotton fabrics

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a flame-retardant post-dyeing method for an all-cotton fabric, which orderly comprises the following steps: a woven fabric is subjected to pretreatment, then flame-retardant treatment, and then ecological finishing, and the dyeing is performed after the ecological finishing. A flame-retardant post-dyeing process of the all-cotton fabric is to improve and adjust the prior flame-retardant process; and a face fabric is subjected to pretreatment, then flame-retardant working procedure, and then other working procedures such as dyeing and so on. Through the adjustment, the damage of the flame-retardant working procedure to dyes is avoided, and the quality of the dyeing is improved.

Description

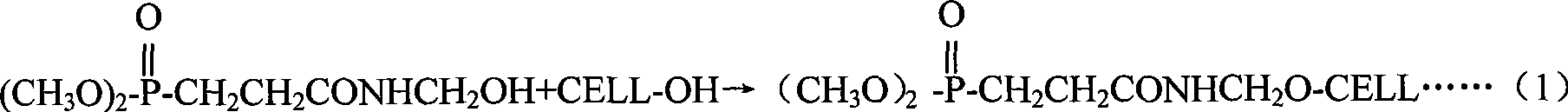

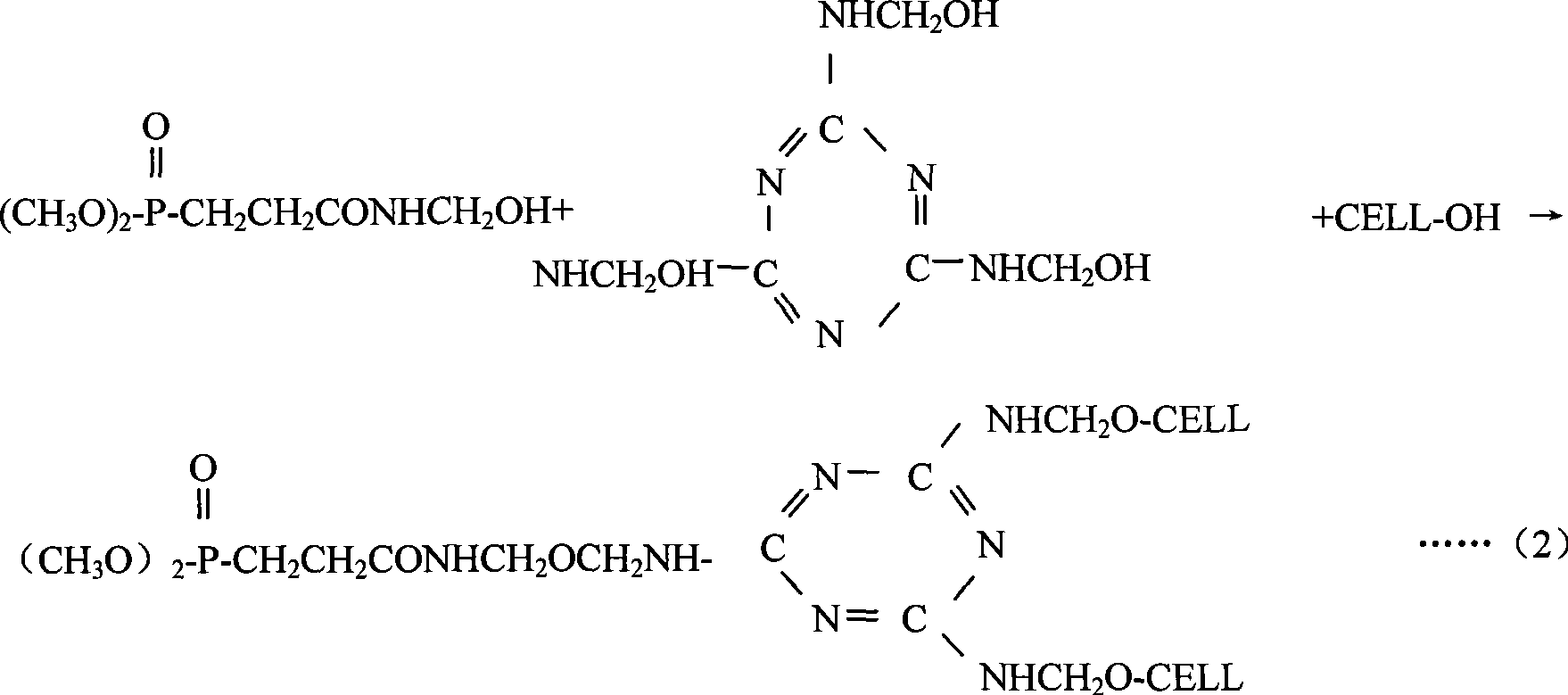

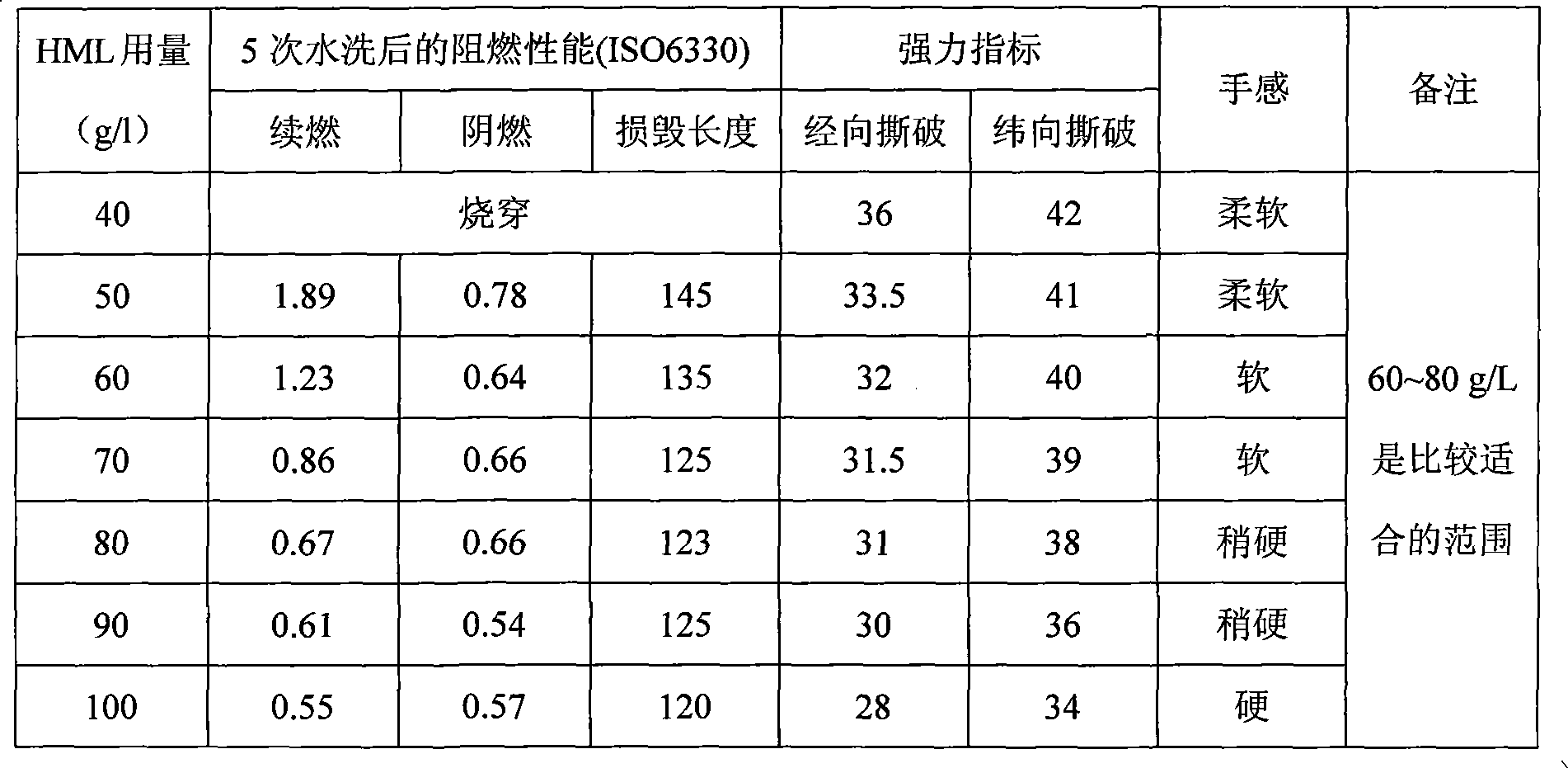

Flame-retardant post-dyeing method of cotton fabric Technical field: The invention relates to a fabric flame-retardant processing method. Background technique: With the development of science and technology and the continuous improvement of living standards, people are gradually paying attention to health and safety, and many jobs are gradually equipped with flame-retardant protective clothing. In addition to the previous fire protection and smelting industries equipped with flame retardant clothing, petrochemical, coal mines, ships, military and other departments have also begun to equip flame retardant protective clothing. With the trend of flame-retardant protective clothing replacing work clothes, people have higher requirements for flame-retardant fabrics. At present, customers not only require the flame retardant performance of the fabric to meet the standard, but also put forward quite high requirements for the wearing performance of the fabric. The merchants prop...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06M13/248D06M101/06D06P3/60D06M15/423D06M13/447

Inventor 张恒山缪卫东施洪权王龙章明建

Owner 南通东升艾克特种纺织防护面料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com