Reinforced heat-insulation three-dimensional fabric

A technology of three-dimensional fabrics and short fibers, which is applied in the field of reinforced and heat-insulating three-dimensional fabrics. It can solve the problems of unseen and low compressive strength in physical properties, and achieve good fire resistance and good compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment, technical scheme of the present invention is described in further detail:

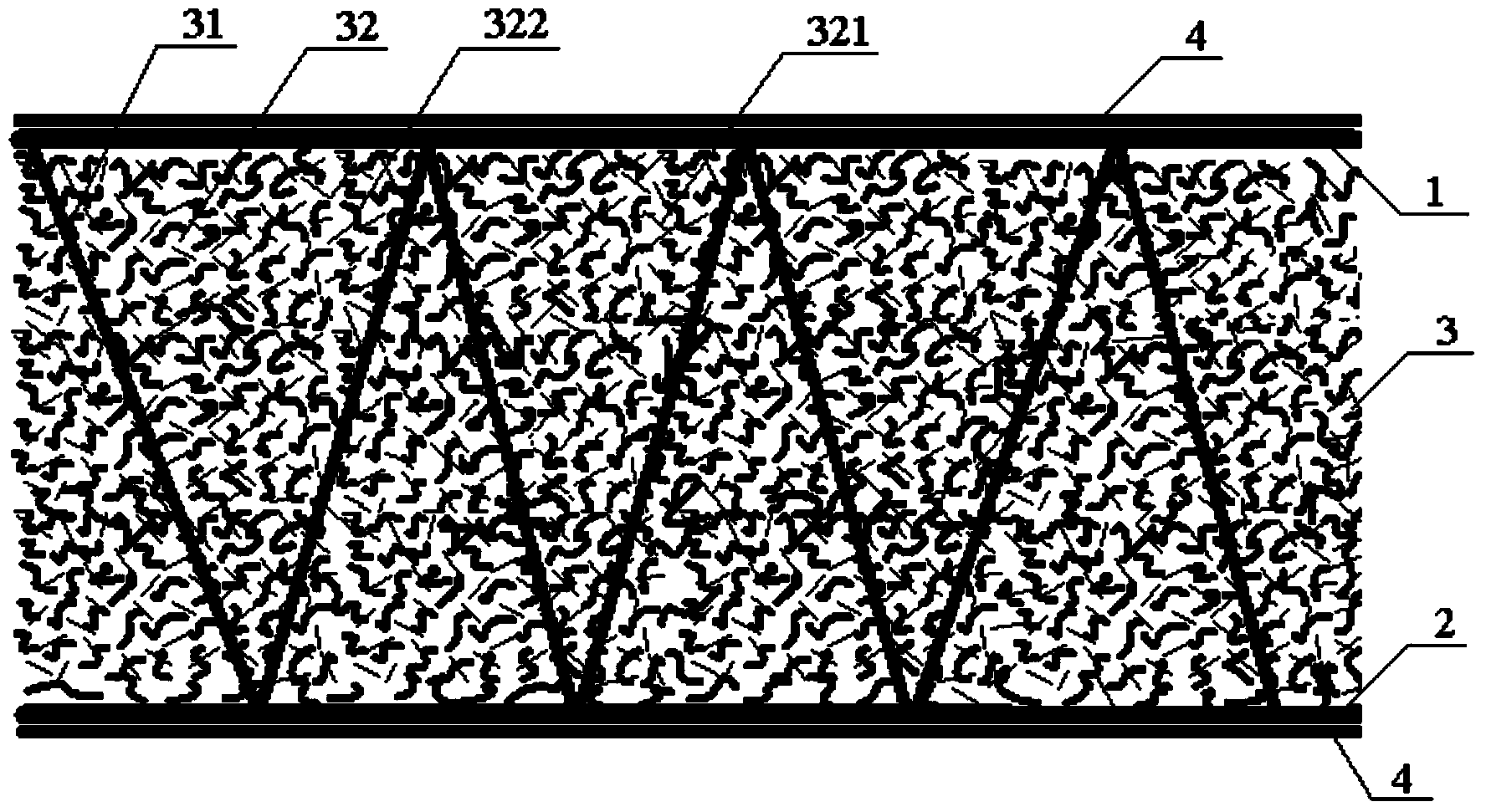

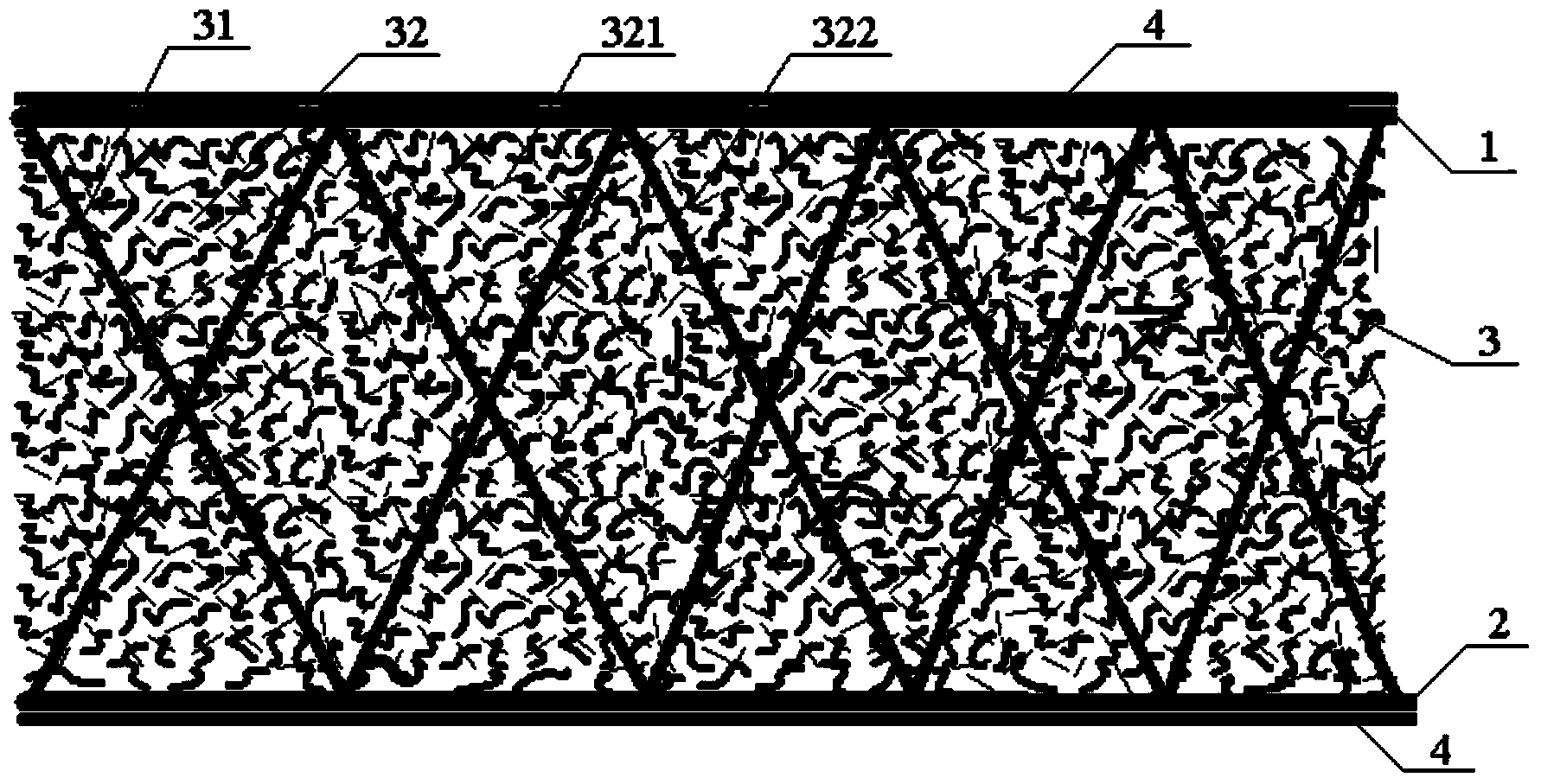

[0019] Such as figure 1 and figure 2 Shown: a reinforced, heat-insulating three-dimensional fabric provided by the present invention, comprising an upper surface layer 1, a lower surface layer 2, and an intermediate layer 3 disposed between the upper and lower surface layers, the intermediate layer 3 comprising spacer filaments 31 and silica airgel 32 doped with whiskers 321 or / and reinforcing short fibers 322, the silica airgel 32 is evenly filled in several intervals formed by the arrangement of spacer filaments 31; Spacer wire 31 is W-shaped (as figure 1 shown) or X-shape (as figure 2 shown) arrangement structure.

[0020] As a preferred solution, a heat reflective coating 4 is provided on the upper surface layer or / and the lower surface layer to further reduce heat radiation and surface temperature.

[0021] As a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com