Process for rolling large-scale rails into miniature type rails and rollers therefor

A large-scale, steel rail technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of complex pass design, roll axial movement, increase pass wear speed, etc., so as to facilitate automatic production and avoid Axial movement, the effect of increasing the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

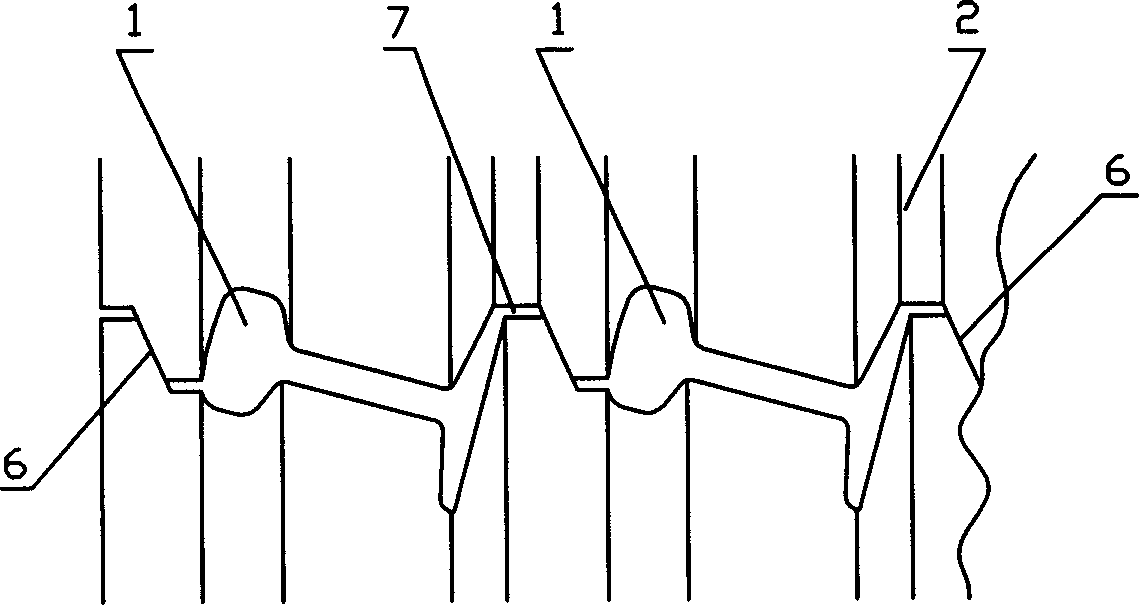

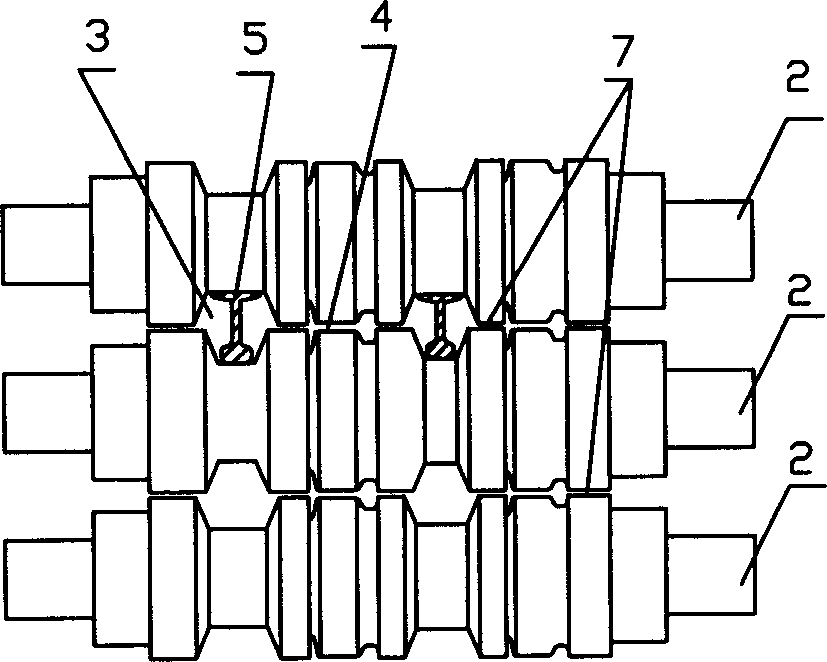

[0030] The method of processing 60kg / m waste heavy rail into 12kg / m regular steel rail, such as Figure 1-4 shown.

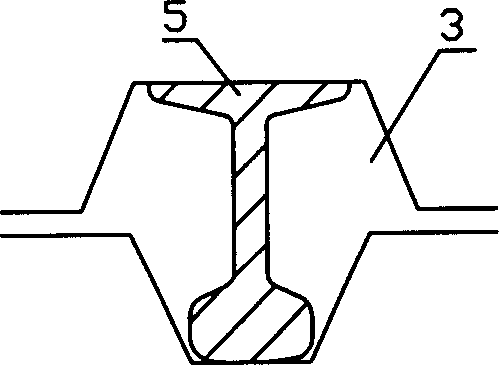

[0031] Design 6 sets of pass patterns for 50kg, 43kg, 30kg, 24kg, 18kg, and 12kg rail passes. Each group of pass types includes a pass type 3 whose symmetry line is perpendicular to the rolling line 7 and a pass type 4 whose symmetry line coincides with the rolling line. Each group of pass types decreases in size according to the pass, and each group of pass types corresponds to a model rails. The pass 3 whose line of symmetry is perpendicular to the rolling line 7, the shape of the rolling grooves on the two rolls 2 are matched with the head and leg shapes of the rail respectively. The pass 4 where the line of symmetry coincides with the rolling line, the rolling grooves on the two rolls 2 are distributed symmetrically with respect to the rolling line 7 . Cut the 60kg / m waste heavy rail into 1.25m / piece, and heat it to 900-1000℃ in a reverberatory furnace. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com