Improvement method and improved structure of decontaminating scraper pan rail

A track and rake bucket technology, applied in the field of metal structures of water conservancy and hydropower projects, can solve the problems of poor economy, incompleteness, labor and time consuming, etc., and achieve the effects of improving installation accuracy and efficiency, simplifying manufacturing and reducing manufacturing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

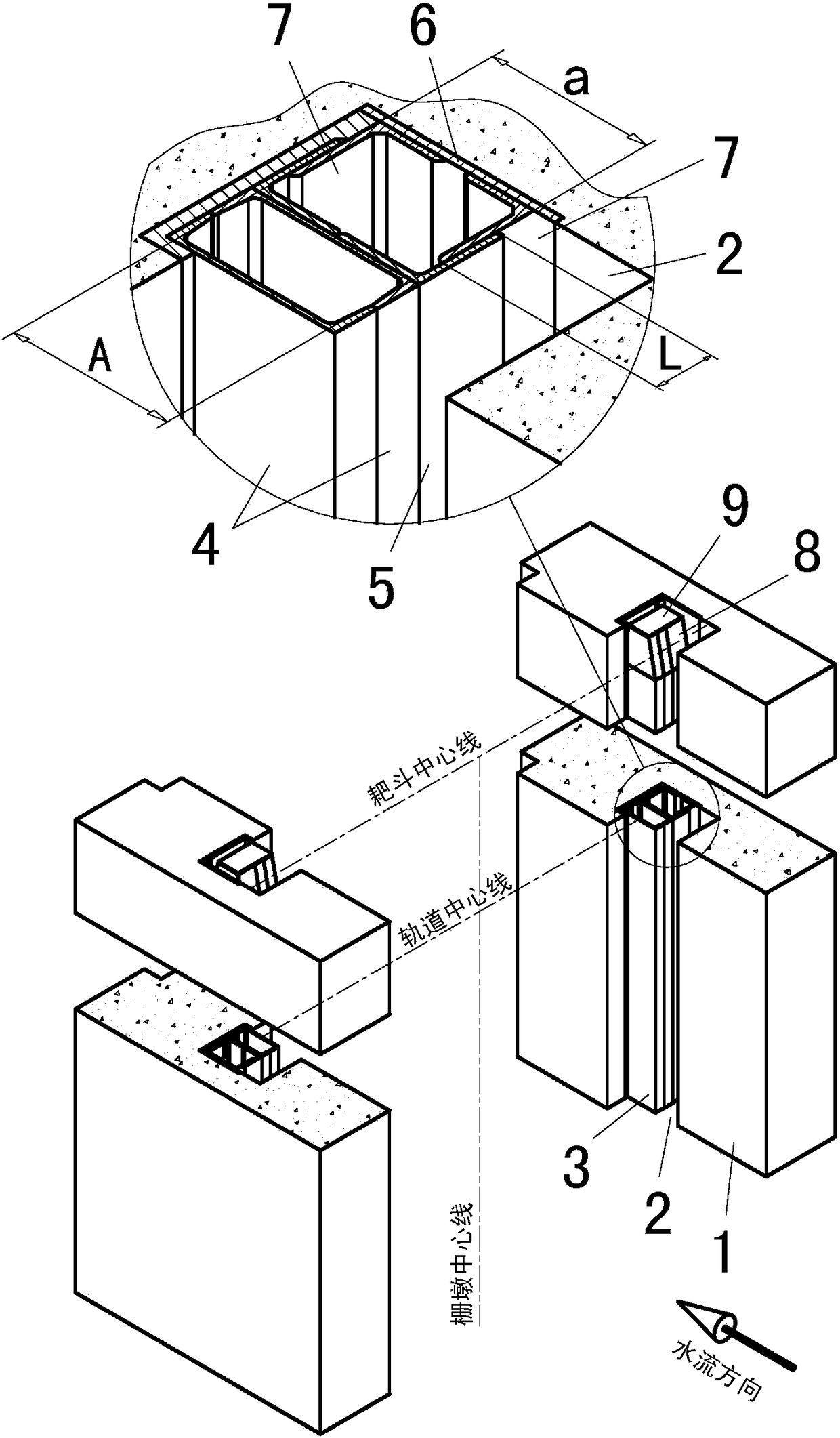

[0018] This example figure 1 As shown, this example is an improvement on the existing technology. The track of the cleaning rake bucket in the prior art generally adopts the I-beam type installed in the second-stage concrete pier. Slow, and the flatness and verticality of the second-stage concrete are not easy to control, which will cause the bucket of the cleaning machine to fail to enter the groove. The second-stage concrete must be chiseled and polished on site, which is labor-intensive and time-consuming. The economy is also poor, especially for larger height The dirt cleaning rake bucket track is more prominent, so the prior art is still not perfect enough.

[0019] The cleaning rake bucket track of this example adopts combined track 3. The combined track 3 is welded by two channel steels 4 and two connecting angle steels 5; the flanges of the two channel steels 4 are butt welded into a closed rectangular section; the two channel steels 4 are firmly welded to the pre-emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overlap length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com