Assembled prefabricated stair and preparation device thereof

A preparation device and assembly type technology, which is applied in the directions of stairs, supply devices, unloading devices, etc., can solve the problems of increasing the workload of staff, time-consuming and laborious, etc., and achieve the effect of easy disassembly and easy demoulding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

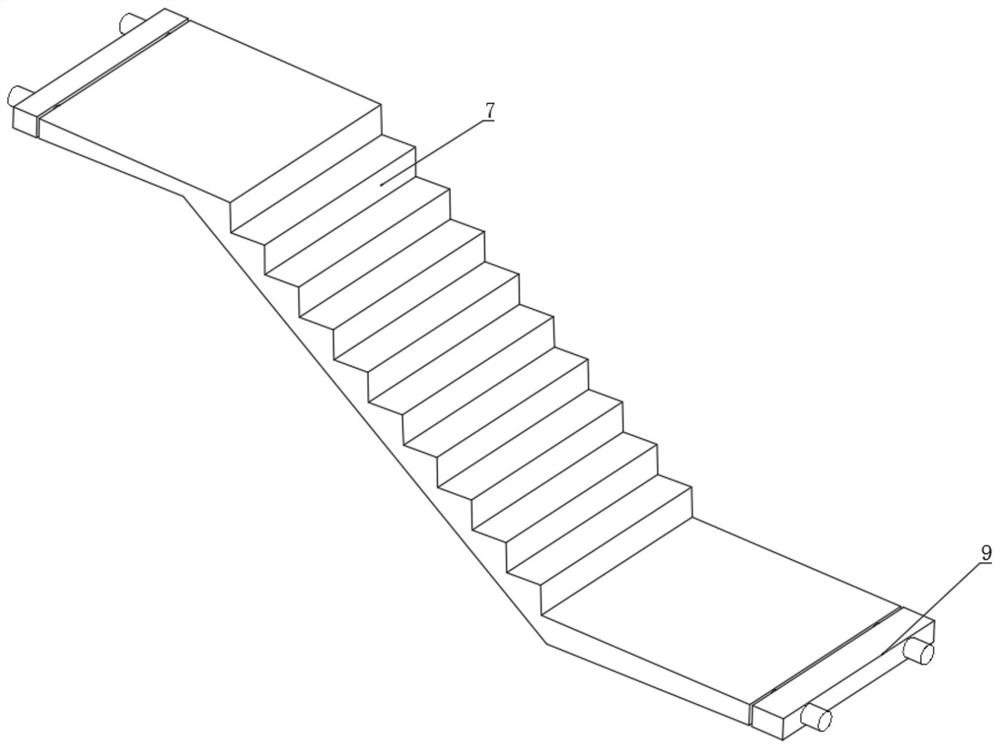

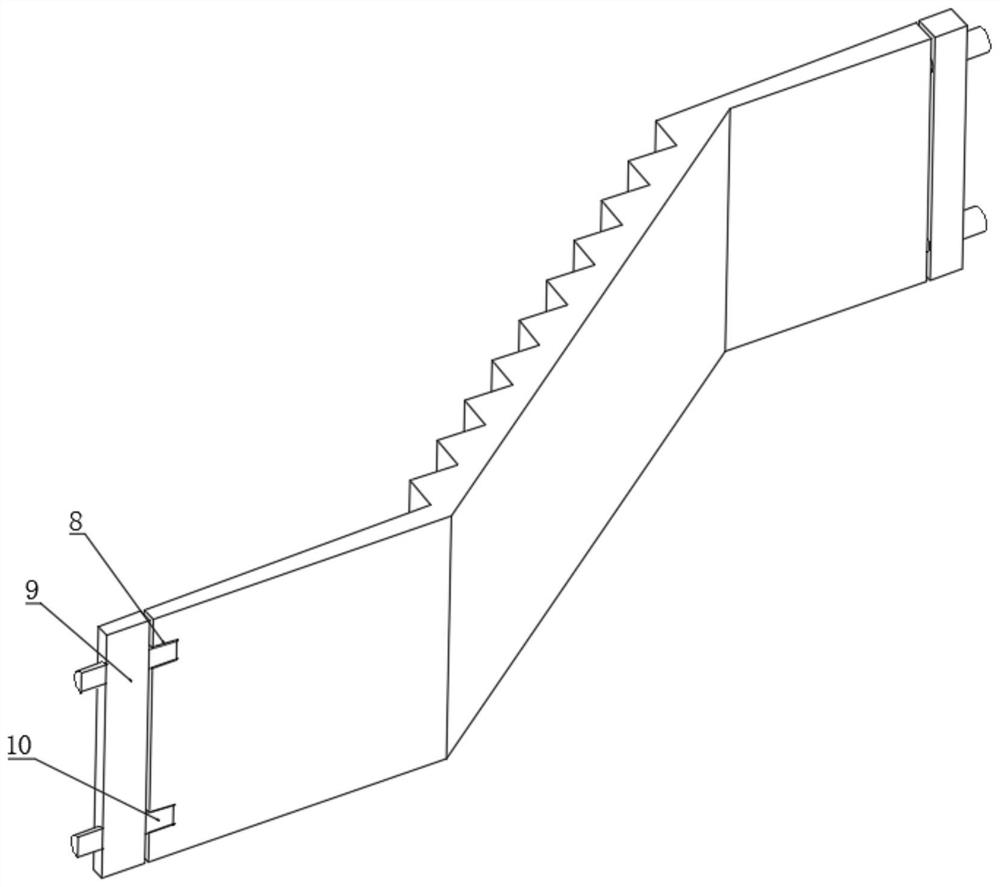

[0049] Embodiment 1: as Figure 1-2 As shown, the present invention provides a technical solution, a prefabricated stair that can be assembled, including a stair base 7, and slots 8 are symmetrically opened at both ends of the stair base 7, and are located inside the two slots 8 on the same side Both clamping blocks 10 are clamped, and one end of the two clamping blocks 10 on the same side is symmetrically fixedly connected to the inner side of the connecting block 9, which is convenient for splicing a plurality of stair bases 7, and the inside of the clamping groove 8 fits with the outer end of the clamping block 10, A block 10 is symmetrically welded on one side of the outer end of the connecting block 9;

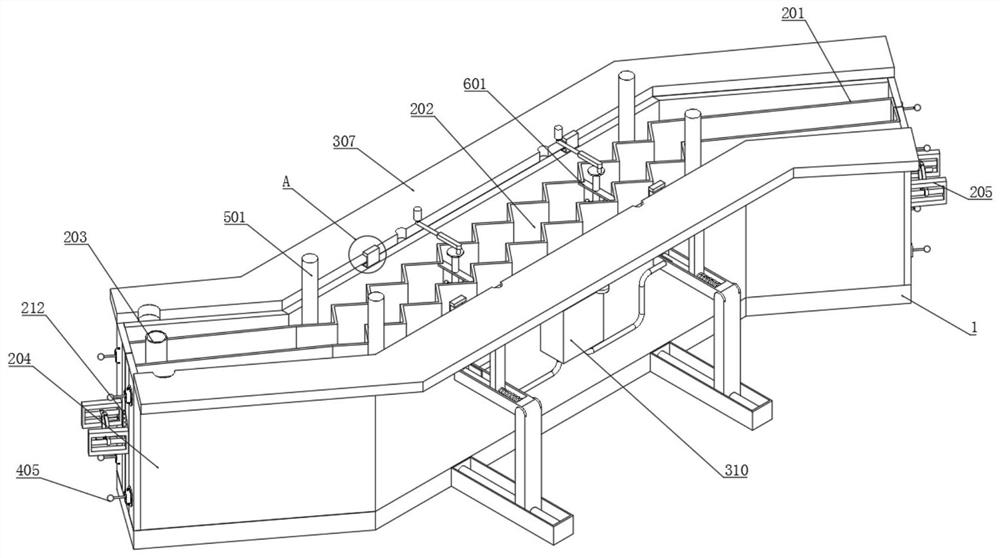

[0050] Such as Figure 3-10 As shown, a preparation device for an assembled prefabricated staircase includes a base 1, a demoulding mechanism 2 is installed at the middle of the top of the base 1, and the demoulding mechanism 2 includes a step plate 201, a ventilation ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com