10G miniaturized EML laser heat sink

A laser and heat sink technology, applied in the design field of 10GEML laser heat sink, to achieve the effect of saving high costs, ensuring high frequency characteristics, and high lithography accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings.

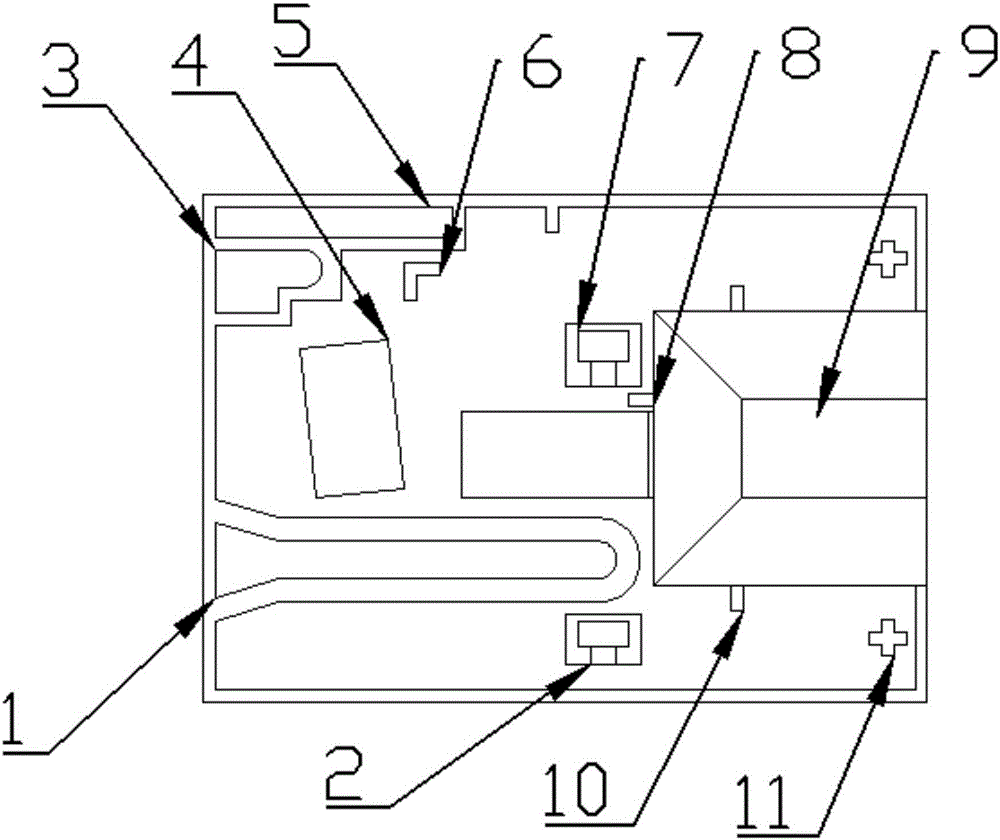

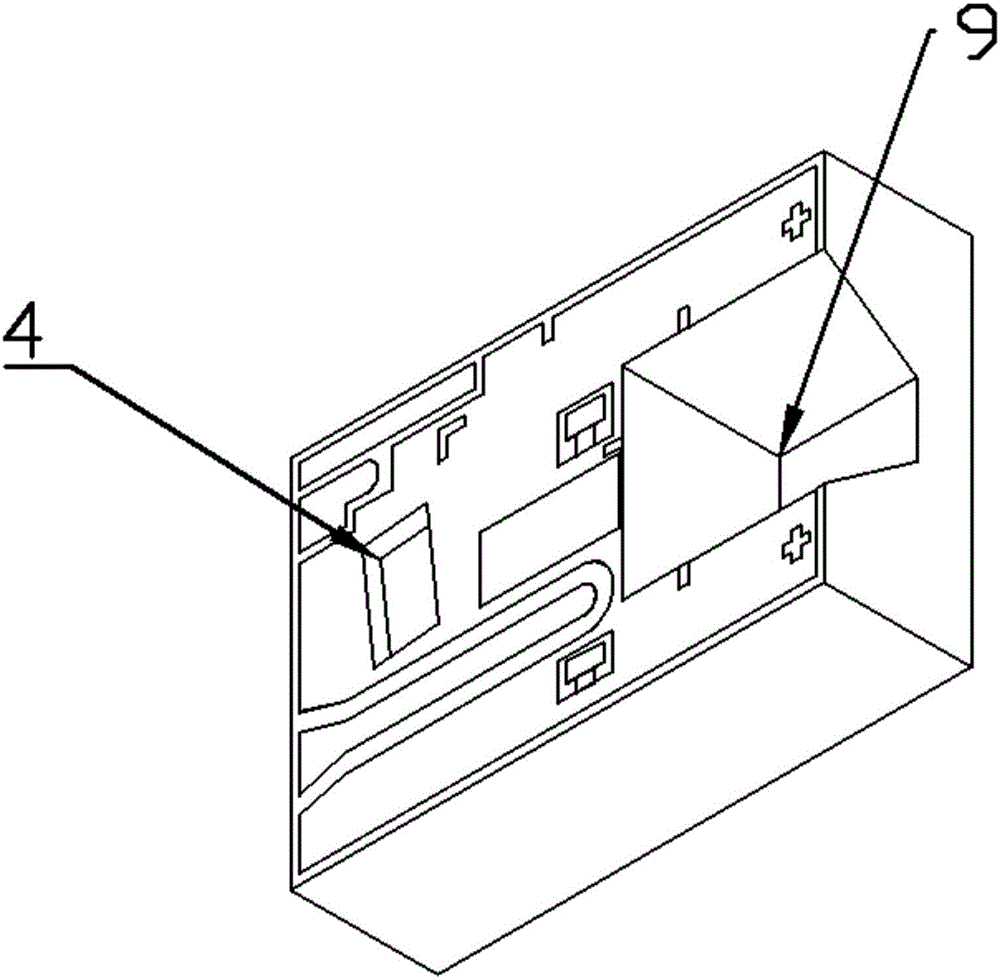

[0028] Such as figure 1 , 2 The heat sink of the 10G miniaturized EML laser shown in the figure adopts a silicon substrate with a size of 2.9×2.0×0.8mm. The silicon substrate is provided with a groove 4 for placing the backlight monitoring component, and the size of the groove 4 is 0.6×0.35×0.1 mm, it is located at the rear position of the laser chip. The key point of the design of the groove 4 is to ensure that the center of the backlight monitoring chip placed in the groove 4 can be aligned with the center of the laser chip, and there is a 6-8 between the laser chip and the laser chip. ° declination angle, so that the low-cost front light-connected chip can be directly used to monitor the backlight of the chip, and at the same time, the influence of reflected light on the forward optical path of the laser can be avoided.

[0029] There i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com