Board grooving machine

A technology for slotting machines and wood boards, which is applied in the direction of slotting machines, mortising machines, wood processing equipment, etc., which can solve the problems of easy opening of slots, high price, and large volume of slotting equipment, so as to achieve convenient adjustment, Improved stability and strong usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

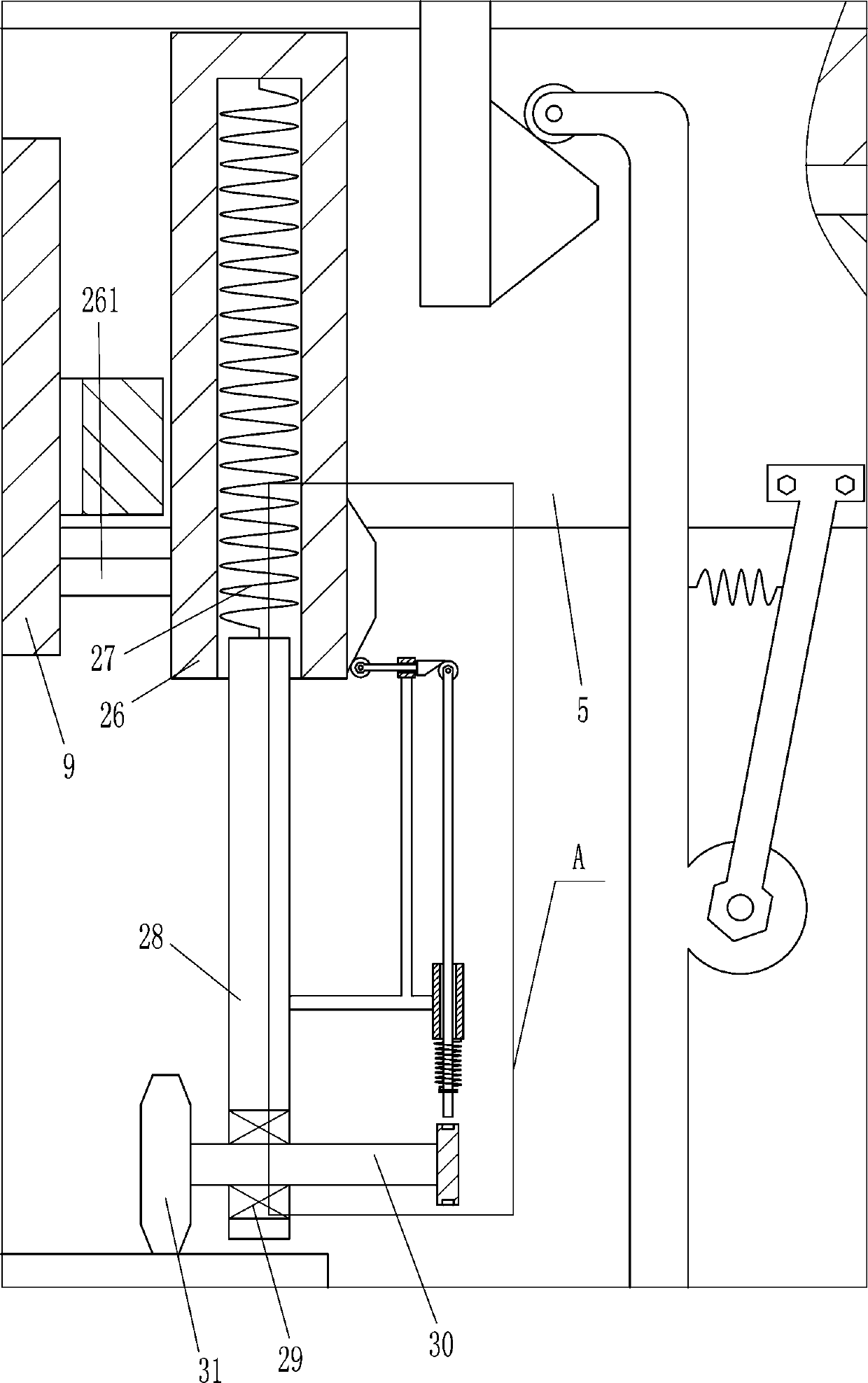

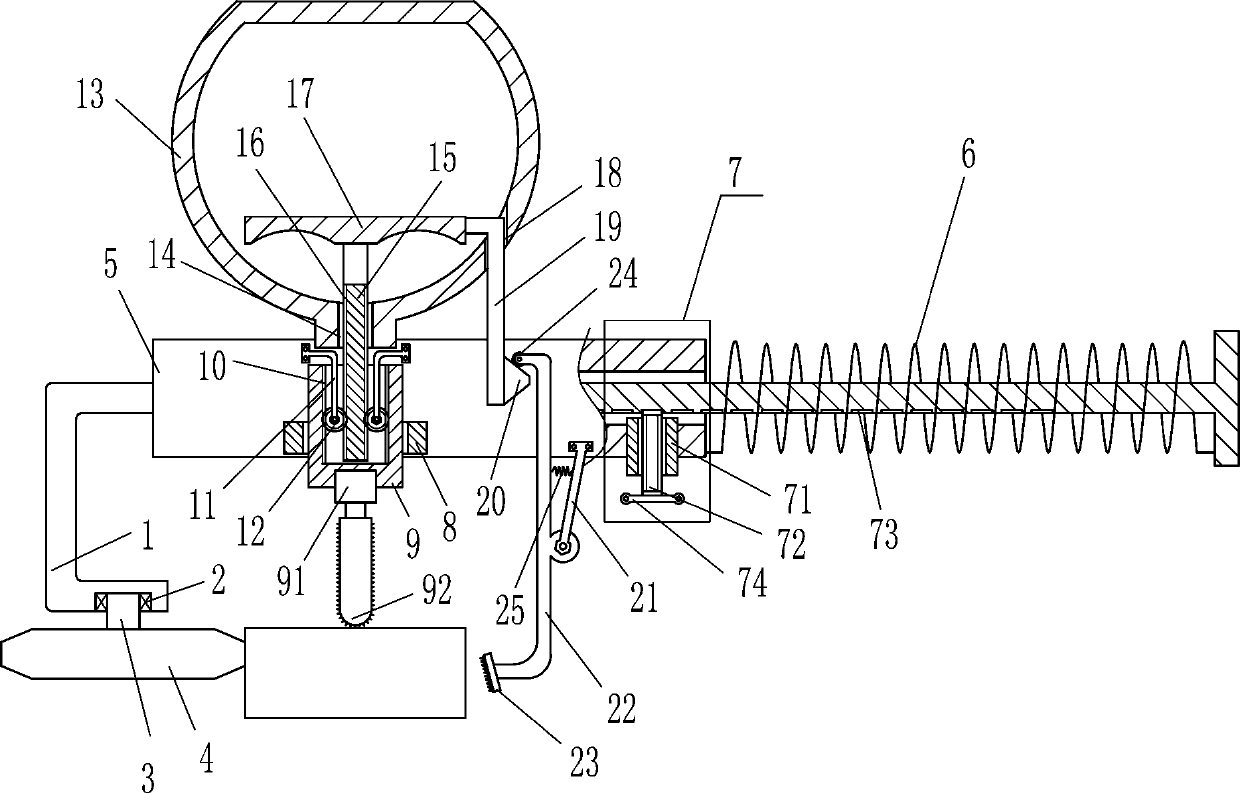

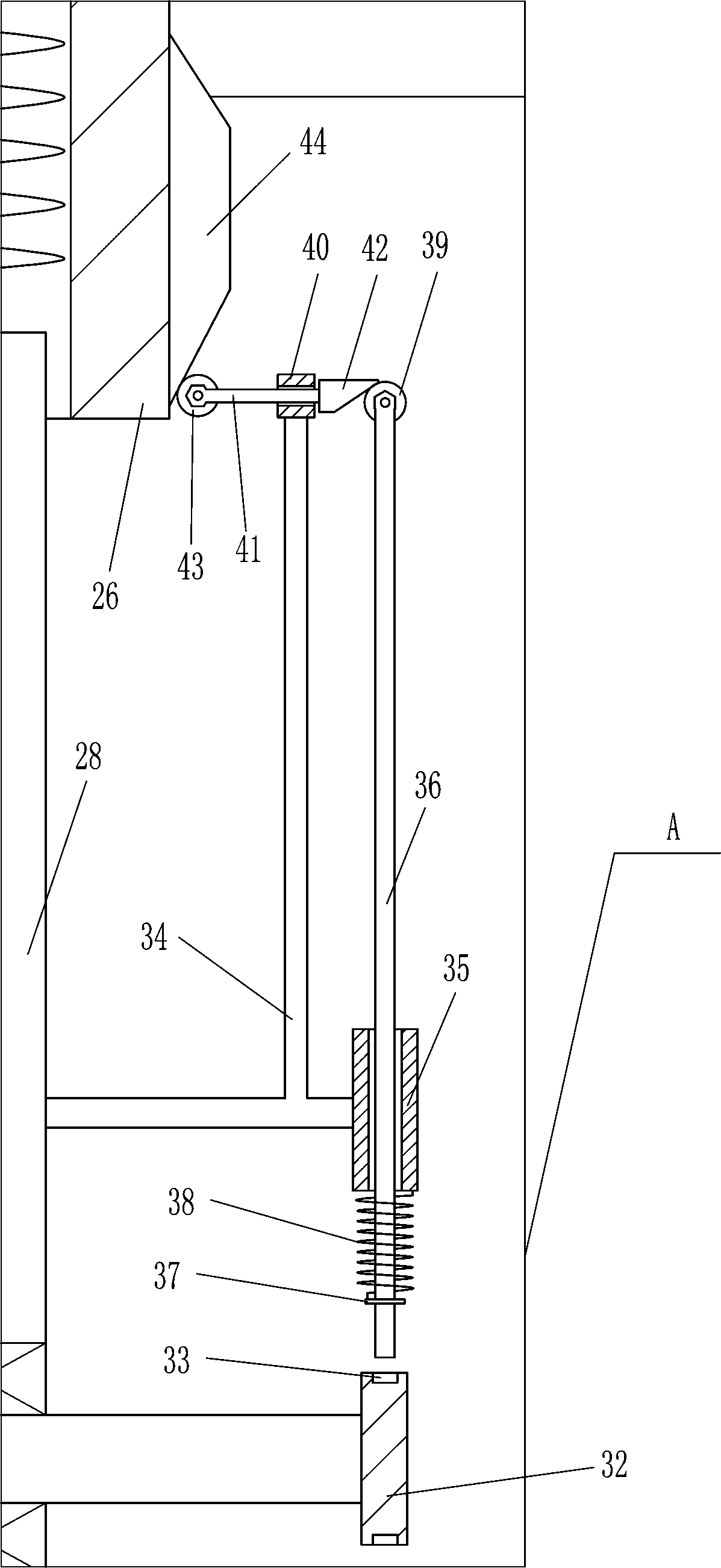

[0016] A wood slotting machine such as figure 1 As shown, it includes a first pole 1, a first bearing 2, a first rotating shaft 3, a first roller 4, a first sliding sleeve 5, a first spring 6, an adjustment device 7, a second sliding sleeve 8, and a hollow sliding rod 9. Motor 91, grooved wheel 92, first rack 10, second pole 11, gear 12, handle 13, first guide rod 15, second rack 16 and handle 17, move inside the first sliding sleeve 5 The formula is provided with a first pole 1, a first bearing 2 is installed embedded in the bottom of the first pole 1, a first rotating shaft 3 is installed on the first bearing 2, a first roller 4 is arranged at the lower end of the first rotating shaft 3, and the first The roller 4 is located below the first sliding sleeve 5, the first spring 6 is wound on the right side of the first pole 1, the left end of the first spring 6 is connected to the right side of the first sliding sleeve 5, and the first spring 6 is connected to the first sliding...

Embodiment 2

[0018] A wood slotting machine such as figure 1 As shown, it includes a first pole 1, a first bearing 2, a first rotating shaft 3, a first roller 4, a first sliding sleeve 5, a first spring 6, an adjustment device 7, a second sliding sleeve 8, and a hollow sliding rod 9. Motor 91, grooved wheel 92, first rack 10, second pole 11, gear 12, handle 13, first guide rod 15, second rack 16 and handle 17, move inside the first sliding sleeve 5 The formula is provided with a first pole 1, a first bearing 2 is installed embedded in the bottom of the first pole 1, a first rotating shaft 3 is installed on the first bearing 2, a first roller 4 is arranged at the lower end of the first rotating shaft 3, and the first The roller 4 is located below the first sliding sleeve 5, the right side of the first pole 1 is wound with a first spring 6, the left end of the first spring 6 is connected to the right side of the first sliding sleeve 5, and the first sliding sleeve 5 is provided with an adjus...

Embodiment 3

[0021] A wood slotting machine such as figure 1 As shown, it includes a first pole 1, a first bearing 2, a first rotating shaft 3, a first roller 4, a first sliding sleeve 5, a first spring 6, an adjustment device 7, a second sliding sleeve 8, and a hollow sliding rod 9. Motor 91, grooved wheel 92, first rack 10, second pole 11, gear 12, handle 13, first guide rod 15, second rack 16 and handle 17, move inside the first sliding sleeve 5 The formula is provided with a first pole 1, a first bearing 2 is installed embedded in the bottom of the first pole 1, a first rotating shaft 3 is installed on the first bearing 2, a first roller 4 is arranged at the lower end of the first rotating shaft 3, and the first The roller 4 is located below the first sliding sleeve 5, the right side of the first pole 1 is wound with a first spring 6, the left end of the first spring 6 is connected to the right side of the first sliding sleeve 5, and the first sliding sleeve 5 is provided with an adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com