Solid wood composite cork floor and making method thereof

A solid wood composite and cork flooring technology, applied in the field of wood flooring, can solve the mechanical properties of MDF, foot feel and moisture-proof performance, structural visual effect limitations, no cork heat preservation, sound insulation, sound absorption, insulation, antistatic, and poor structural stability. Easy deformation and other problems, to achieve the effect of rich colors, lack of elasticity, and similar overall material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

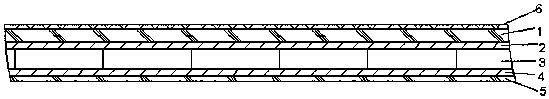

[0045] A solid wood composite cork floor, comprising a wear-resistant layer (6), an upper cork layer (1), an upper veneer (2), a middle layer (3), a lower veneer (4), and a lower cork layer (5) from top to bottom ), the lower surface of the wear-resistant layer (6) is attached to the upper surface of the upper cork layer (1), the lower surface of the upper cork layer (1) is attached to the upper surface of the upper veneer (2), and the upper veneer ( 2) The lower surface is attached to the upper surface of the middle layer (3), the lower surface of the middle layer (3) is attached to the upper surface of the lower veneer (4), and the upper surface of the lower veneer (4) is attached to the lower cork layer (5) Surface fit.

Embodiment 2

[0047] A solid wood composite cork floor, comprising a body, the body is a layered structure, sequentially including a wear-resistant layer (6), an upper cork layer (1), an upper veneer (2), a middle layer (3), The lower veneer (4), the lower cork layer (5), the lower surface of the wear-resistant layer (6) is attached to the upper surface of the upper cork layer (1), and the lower surface of the upper cork layer (1) is connected to the upper veneer (2) ), the upper surface of the upper veneer (2) is bonded to the upper surface of the middle layer (3), the lower surface of the middle layer (3) is bonded to the upper surface of the lower veneer (4), and the lower veneer (4) Laminate with the upper surface of the lower cork layer (5). The thickness of the upper cork layer (1) is not less than 2.0mm, and the thickness of the lower cork layer (5) is not less than 1.0mm, so as to ensure the elasticity of the floor.

Embodiment 3

[0049] A solid wood composite cork floor, comprising a body, the body is a layered structure, sequentially including a wear-resistant layer (6), an upper cork layer (1), an upper veneer (2), a middle layer (3), The lower veneer (4), the lower cork layer (5), the lower surface of the wear-resistant layer (6) is attached to the upper surface of the upper cork layer (1), and the lower surface of the upper cork layer (1) is connected to the upper veneer (2) ), the upper surface of the upper veneer (2) is bonded to the upper surface of the middle layer (3), the lower surface of the middle layer (3) is bonded to the upper surface of the lower veneer (4), and the lower veneer (4) Laminate with the upper surface of the lower cork layer (5). The thickness of the upper cork layer (1) is not less than 2.0mm, and the thickness of the lower cork layer (5) is not less than 1.0mm, so as to ensure the elasticity of the floor. The solid wood material layer includes an upper veneer (2), a midd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com