Wood cutting equipment for woodworking

A technology for cutting equipment and wood, applied in the field of wood cutting equipment for woodworking, can solve the problems of inconvenient cutting, deviation of cutting demand, waste of raw materials, etc., and achieve the effect of quick collection and sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

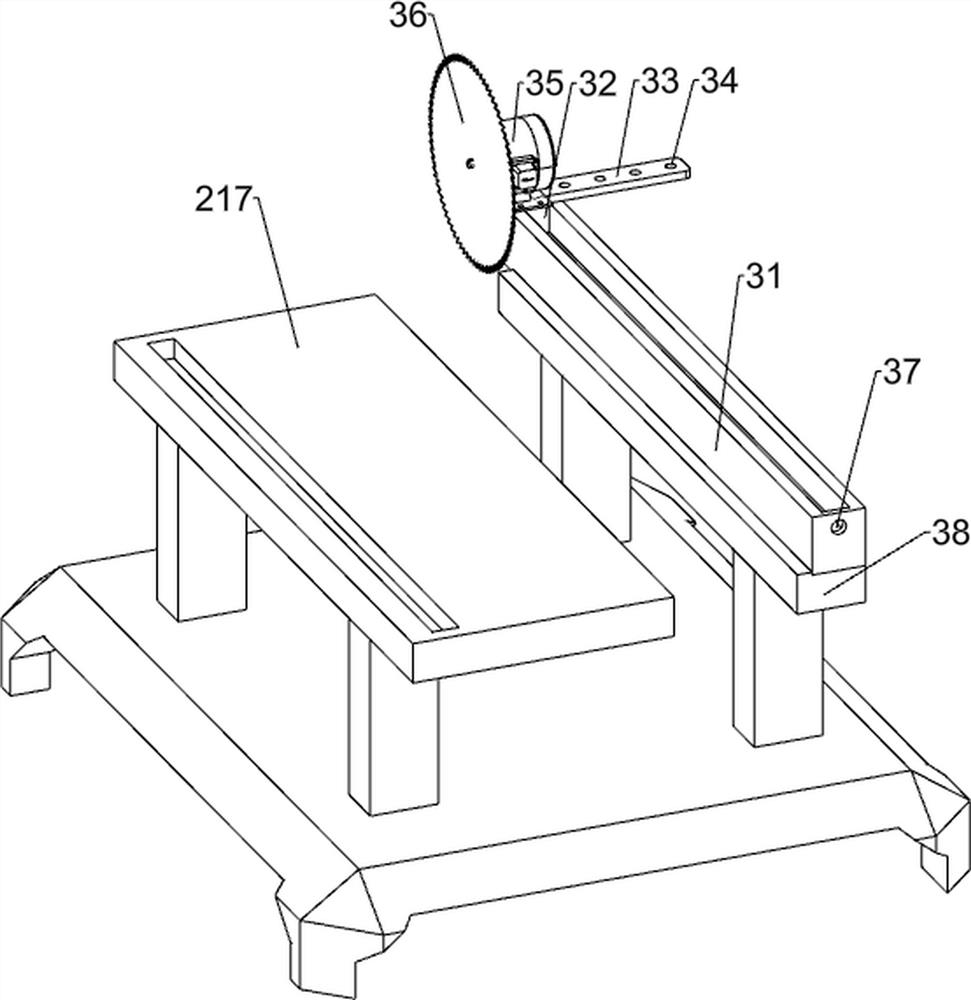

[0067] A kind of wood cutting equipment for carpentry, such as figure 1 As shown, it includes a mounting frame 1, a clamping mechanism 2 and a cutting mechanism 3. The clamping mechanism 2 is provided on the front side of the top of the mounting frame 1, and the cutting mechanism 3 is provided on the rear side of the top of the mounting frame 1.

[0068]The staff first places the wood in the clamping mechanism 2, and manually fixes the wood, then the staff starts the cutting mechanism 3 to work, and the cutting mechanism 3 runs to cut the wood in the clamping mechanism 2. After all the wood is cut, The staff closes the cutting mechanism 3, the cutting mechanism 3 stops running, and the staff can collect the cut wood.

Embodiment 2

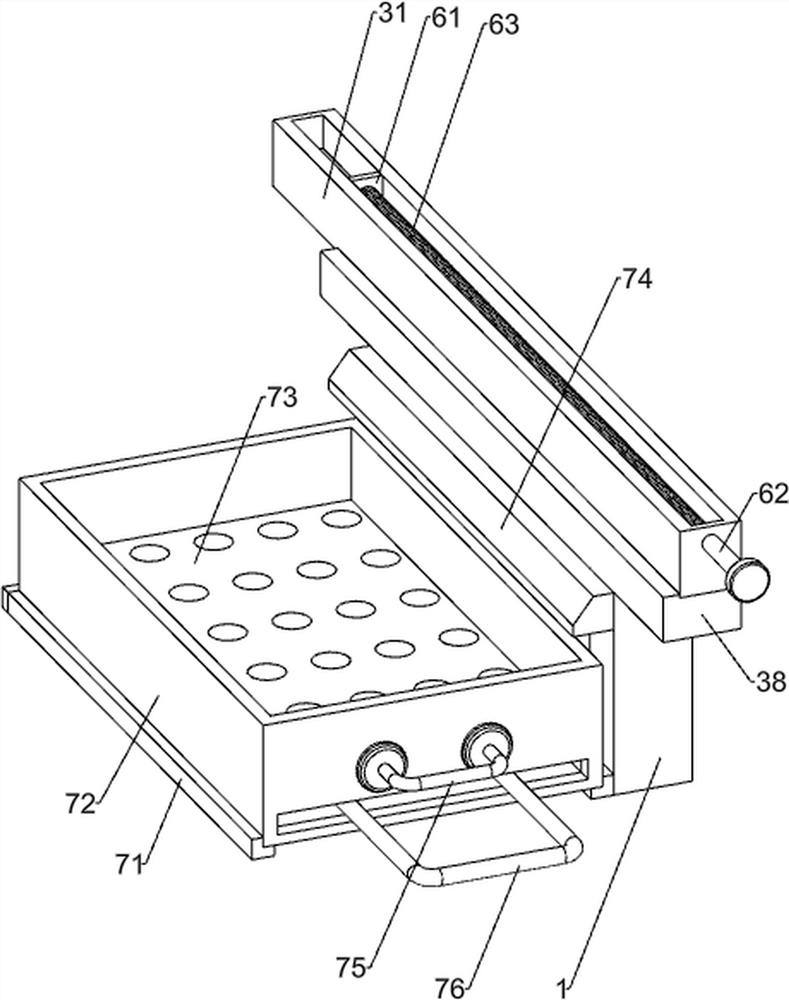

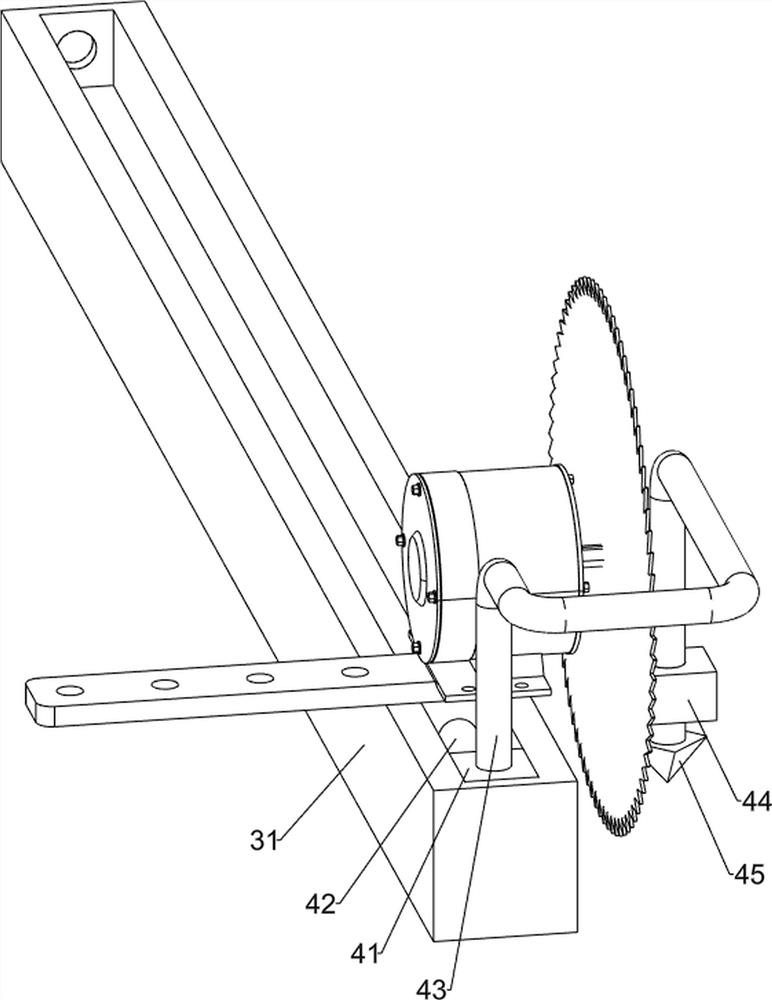

[0070] On the basis of Example 1, such as figure 2 and image 3 As shown, the clamping mechanism 2 includes a first sliding sleeve 21, a turntable 22, a first slider 23, a first clamping plate 24, a first spring 25, a second clamping plate 26, a first mounting plate 27, a second mounting plate Plate 28, first connecting block 29, first screw 210, first bevel gear 211, second sliding sleeve 212, second bevel gear 213, worm 214, first worm wheel 215, second worm wheel 216, first support plate 217 and the rocking bar 218, the front side of the top of the mounting frame 1 is provided with a first support plate 217, the front side of the first support plate 217 is provided with a chute, the front side of the first support plate 217 is provided with a first sliding sleeve 21, and the first sliding sleeve 21 front side middle rotation type is provided with turntable 22, and turntable 22 is provided with rocking bar 218, and first support plate 217 chute interior sliding type is sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com