Combined type multifunctional diamond saw blade

A diamond saw blade, multi-functional technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of increased procurement cost, unfavorable carrying, combined installation, etc., to achieve complete functions, reasonable internal structure design, convenient the effect of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

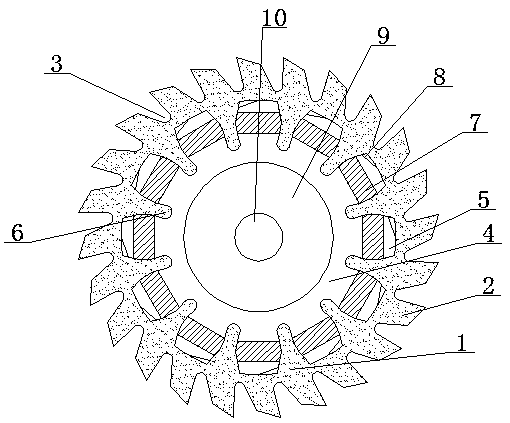

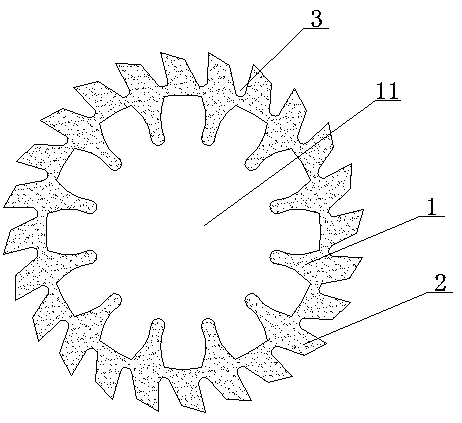

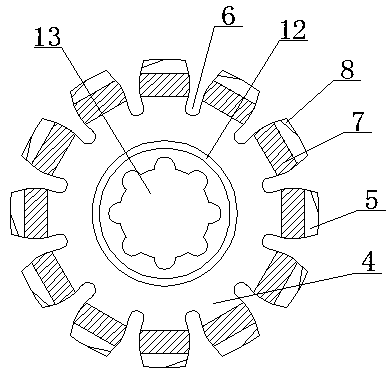

[0019] Example: such as Figure 1-5 As shown, a combined multifunctional diamond saw blade of the present invention includes a cutting blade 1 and a slotted blade 4, the surface of the cutting blade 1 is provided with a plurality of cutting teeth 2, the middle of the cutting blade 1 is provided with a first placement hole 11, The inside of the first placement hole 11 is covered with a slotted piece 4, the surface of the slotted piece 4 is provided with a plurality of slotted teeth 5, and the surface of each slotted tooth 5 is fixedly connected with a slotted blade 8, and the sides of each slotted tooth 5 are A polishing sheet 7 is fixedly connected, and a second placement hole 13 is provided in the middle of the slotted sheet 4. A connecting sleeve 14 is set inside the second placement hole 13, and a second connecting hole 15 is provided inside the middle of the connecting sleeve 14. The slotted sheet 4 The limiting sleeve 9 is placed in the middle and on the outer periphery o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com