Device and method for ultrasonic tank demulsification

An ultrasonic and demulsification technology, which is applied in the direction of electric/magnetic dehydration/demulsification, separation of immiscible liquids, chemical/physical/physicochemical processes using energy, etc., can solve the problems affecting the normal progress of sewage treatment and standard discharge Problems such as rising oil content and COD value in drainage, inconvenient inspection and maintenance, etc., to achieve the effect of mobile detachable, easy maintenance, installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

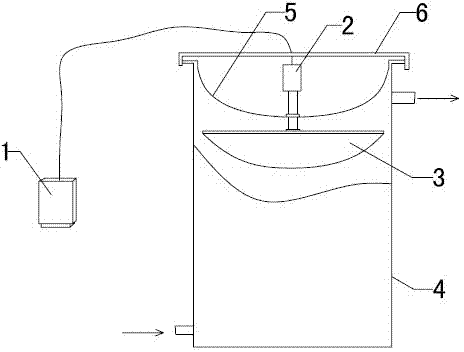

[0032] Such as figure 1 As shown, the head of the top cover 5 of the demulsification tank is installed in a concave manner, and the ultrasonic transducer 2 is connected to the inside of the tank using a conventional connection method, welding or flange compression connection, and the top of the tank is to prevent rain accumulation Water, the rainproof cover plate 6 is set. A single set of ultrasonic transducer distribution device is installed in the demulsification tank 4, and the single set of ultrasonic transducer distribution device is only installed on the top of the demulsification tank. The ultrasonic generator 1 is installed in an explosion-proof control cabinet, and the ultrasonic generator 1 is connected with the ultrasonic transducer 2 through a power cable.

[0033] The lower part of the ultrasonic distributor 3 is stamped with a thin steel plate to form a head-type structure, and the upper part of the ultrasonic distributor 3 is provided with a rainproof cover 6 m...

Embodiment 2

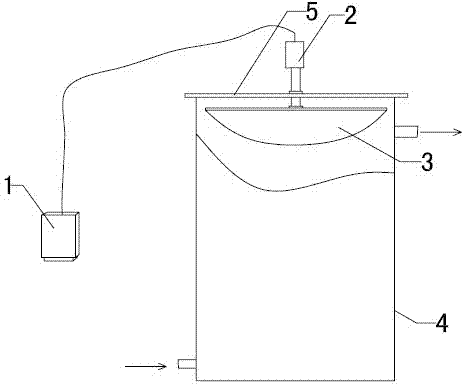

[0037] Such as figure 2 The top cover 5 of the demulsification tank of the ultrasonic tank type demulsification device shown is a flat head, and other devices are the same as in Embodiment 1.

[0038] The feed port of the ultrasonic tank demulsifier is connected to the crude oil pipeline with 1.5% water content. At 20°C, the ultrasonic frequency is 40kHz, and the ultrasonic sound intensity is 0.3 w / cm 2 . Transported by the crude oil pump, the water-containing crude oil passes through the feed port at a speed of 2m 3 / min. It enters from the lower part of the demulsification tank through the pipeline, and after the tank-type demulsification effect of a single set of ultrasonic transducers and ultrasonic distributors, it is exported from the top of the demulsification tank and introduced into the sedimentation dehydration tank to complete the oil-water separation process. After settling in the settling dehydration tank for 48 hours, the water content of the dirty oil in the...

Embodiment 3

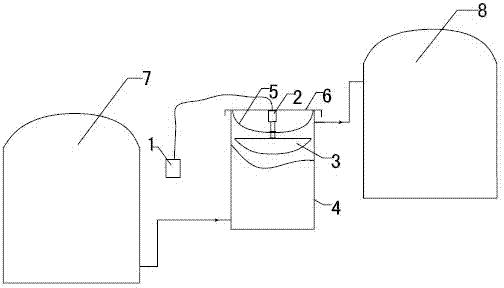

[0040] The device used is the same as in Example 1.

[0041] Install a set of top cover concave type ultrasonic tank demulsification device of the present invention between the dirty oil storage tanks with water content of 7.0%. At 80°C, the ultrasonic frequency is 200kHz, and the ultrasonic sound intensity is 0.1 w / cm 2 . Transported by the crude oil pump, the water-containing sewage oil passes through the feed port at a speed of 2m 3 / min. It enters from the lower part of the demulsification tank through the pipeline, and after the tank-type demulsification effect of a single set of ultrasonic transducers and ultrasonic distributors, it is exported from the top of the demulsification tank and introduced into the sedimentation dehydration tank to complete the oil-water separation process. After settling in the settling dehydration tank for 48 hours, the water content of the dirty oil in the tank was reduced to 1.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com