A kind of belt dryer and drying method for preparing solid phosphoric acid catalyst

A phosphoric acid catalyst and belt dryer technology, applied in progressive dryers, dryers, drying of solid materials, etc., can solve the problems of low automation of dryers, and achieve reasonable internal structure design, convenient cleaning, and improved drying. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

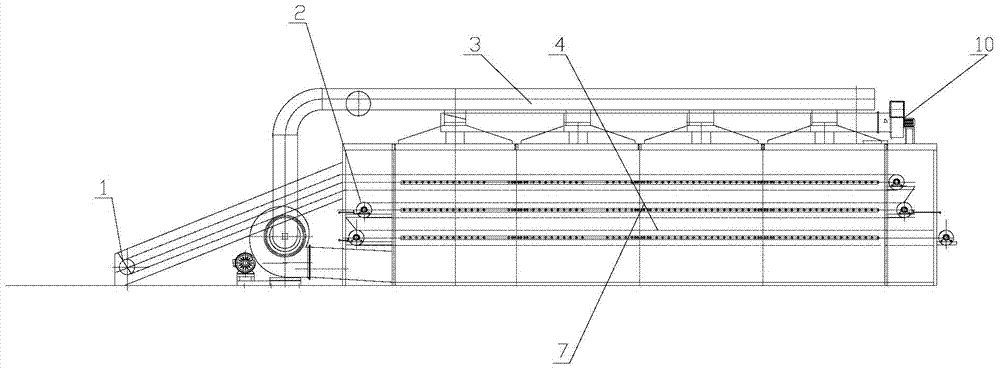

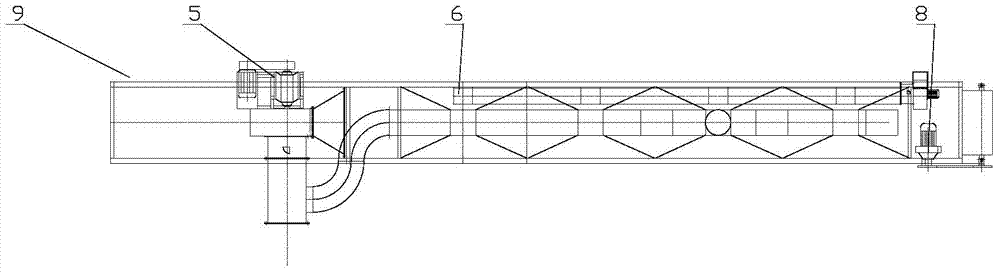

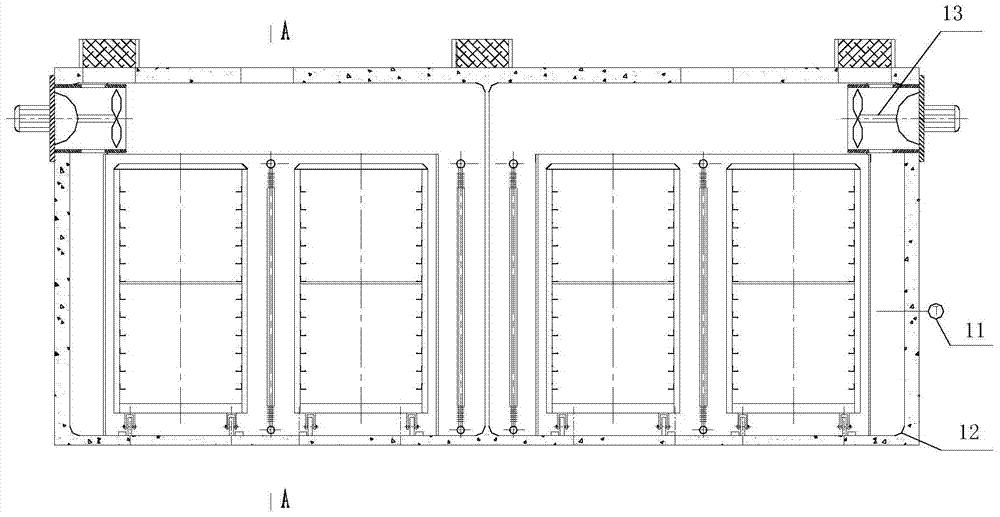

[0036] The present invention is a kind of belt drier used for the preparation of solid phosphoric acid catalyst, such as figure 1 As shown, it puts the material to be dried, that is, the catalyst, into the hopper through the feeder, and the material is conveyed to the inside of the dryer by the conveying mesh belt. The catalyst particles move at a constant speed in the multi-layer belt dryer, falling from top to bottom. , The wet material sandwiched in the middle of the material layer is alternately mixed with the outer dry material to achieve a homogeneous effect.

[0037]During the drying process, the hot air is forced to circulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com