Slotting device for producing antistatic aramid composite floor and method of using slotting device

A composite floor and anti-static technology, which is applied in the direction of slotting machines, mortising machines, wood processing appliances, etc., can solve the problems of not being able to slot the end face of the bottom plate, and the control of the slotting depth is inaccurate, so as to achieve simple structure and easy installation. Easy to fix and slotting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

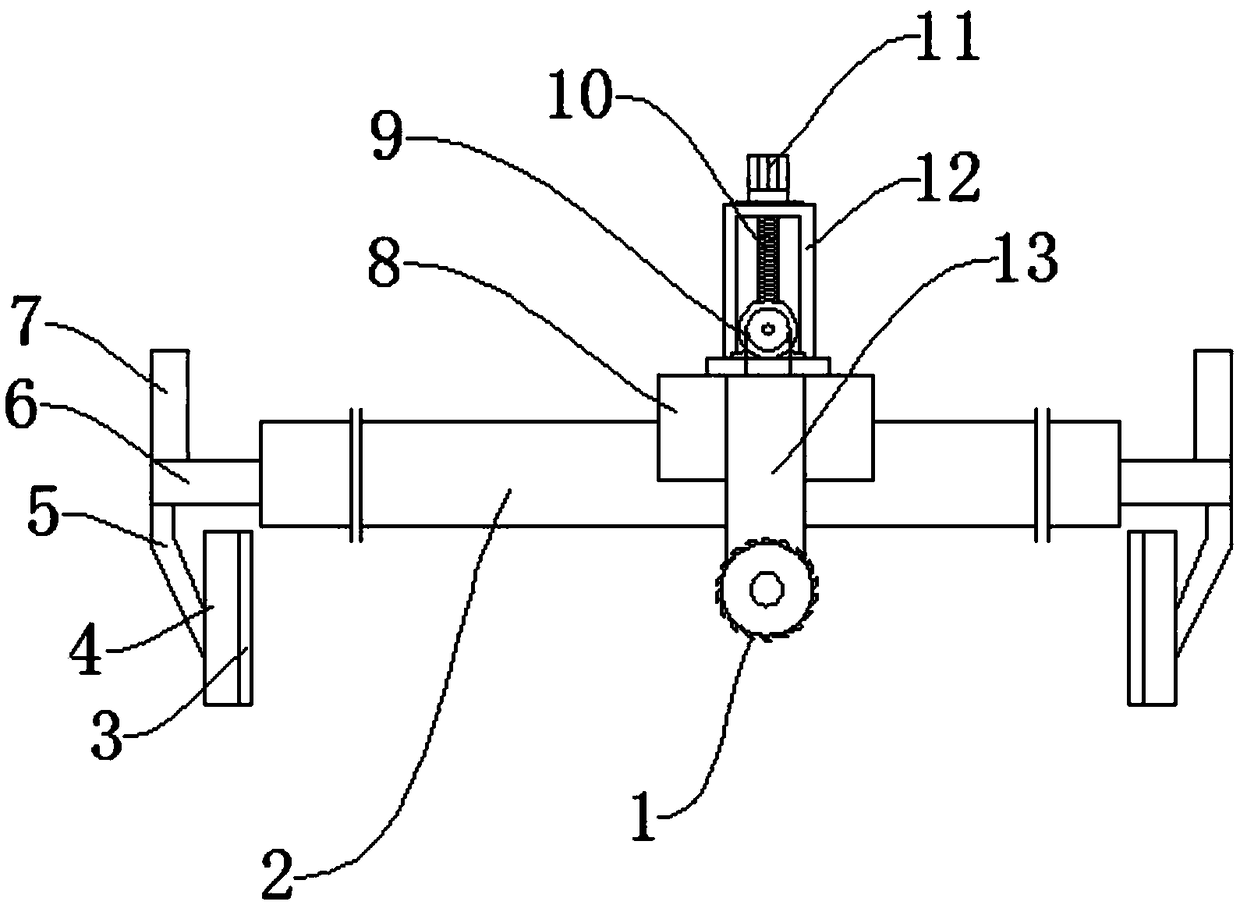

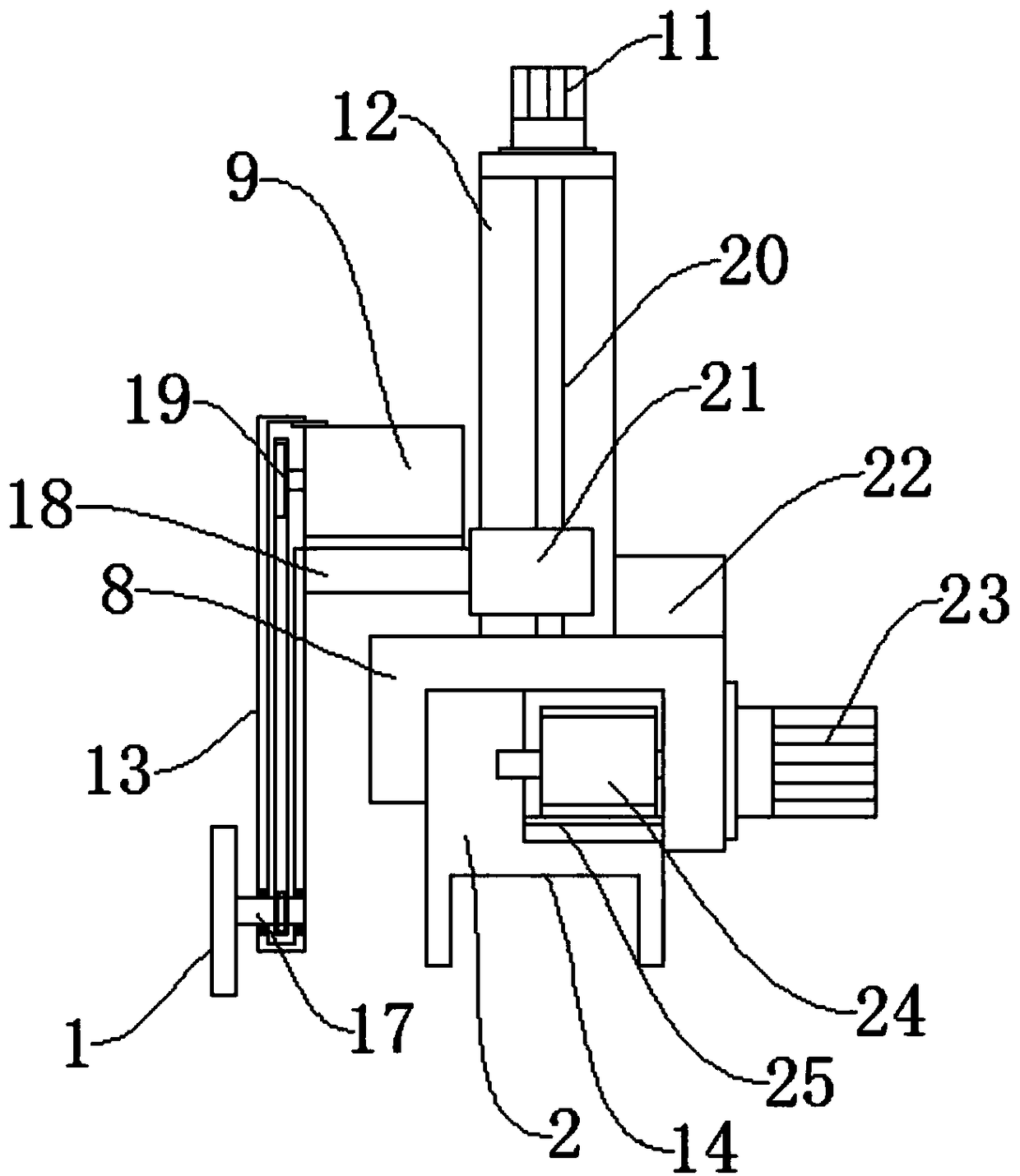

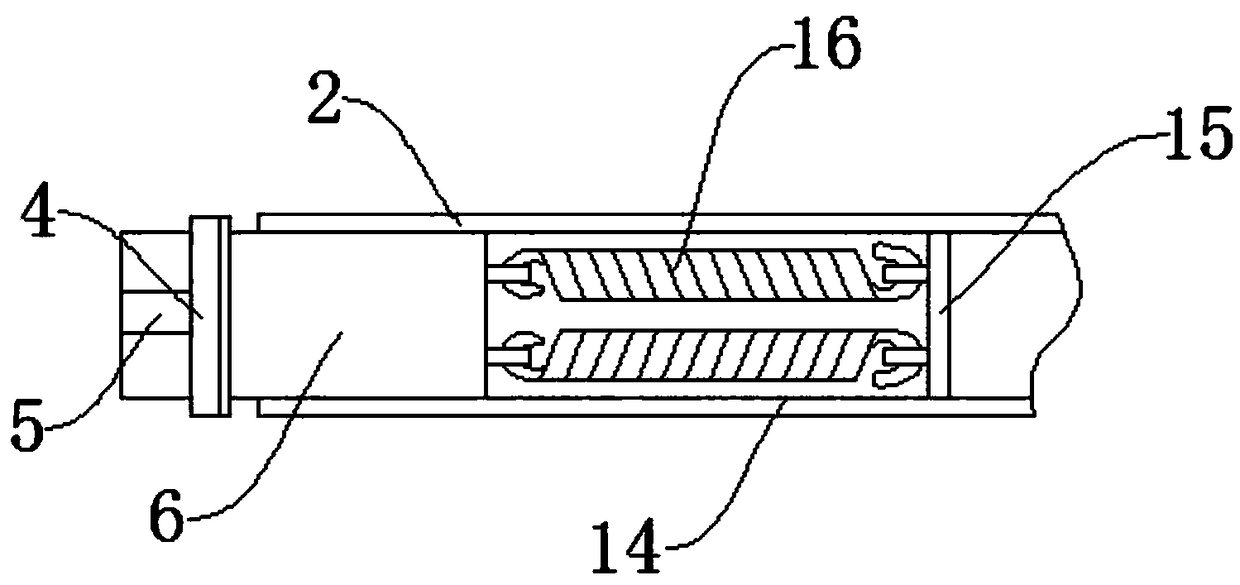

[0031] like Figure 1-Figure 5 As shown, a slotting device for the production of antistatic aramid composite flooring includes a slotting knife 1 and a base 2. A lower installation groove 14 is formed inside the lower end of the base 2, and an internal fixing groove 14 is arranged inside the lower installation groove 14. Plate 15, a return spring 16 is provided on one side of the internal fixing plate 15, a slider 6 is provided on one side of the return spring 16, a handle 7 is provided above the outer end of the slider 6, and a handle 7 is provided on the outer end of the slider 6. A support arm 5 is provided below the end, and a side splint 4 is provided at the end of the support arm 5, and an anti-skid pad 3 is provided on the side of the side splint 4, and a rack 25 is arranged above the base 2, and the rack 25 A hobbing 24 is arranged above, and a horizontal movement seat 8 is arranged above the hobbing 24. A horizontal movement motor 23 is provided on one side of the hor...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is:

[0034]In this embodiment, the internal fixing plate 15 is welded to both ends of the lower installation groove 14, the slider 6 is slidably connected in the lower installation groove 14, and the two ends of the return spring 16 are respectively hooked on On the internal fixing plate 15 and the sliding block 6, at least two returning springs 16 are arranged between the internal fixing plate 15 and the sliding block 6, and the returning springs 16 are always in a stretched state.

[0035] Specifically, such setting can be fixed by utilizing the elastic force of the return spring 16 .

[0036] The present invention also provides a method for using the slotting device for the production of antistatic aramid composite flooring, which is applied to the above slotting device for the production of antistatic aramid composite flooring. When in use, hold the handle 7 and stretch it outward, so that The two side splint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com