Bending forming process for V-shaped groove wood veneer

A bending forming and wood veneer technology, applied in the field of basic craftsmanship, can solve the problems of burrs on the surface of wood veneer, damage to the surface of wood veneer, and easy to turn black and mildew, so as to reduce black and mildew, facilitate processing, The effect of reducing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. The following description of at least one exemplary embodiment is merely illustrative in nature and in no way taken as limiting the invention, its application or uses.

[0054] To keep the following description of the embodiments of the present invention clear and concise, detailed descriptions of known functions and known components are omitted from the present invention.

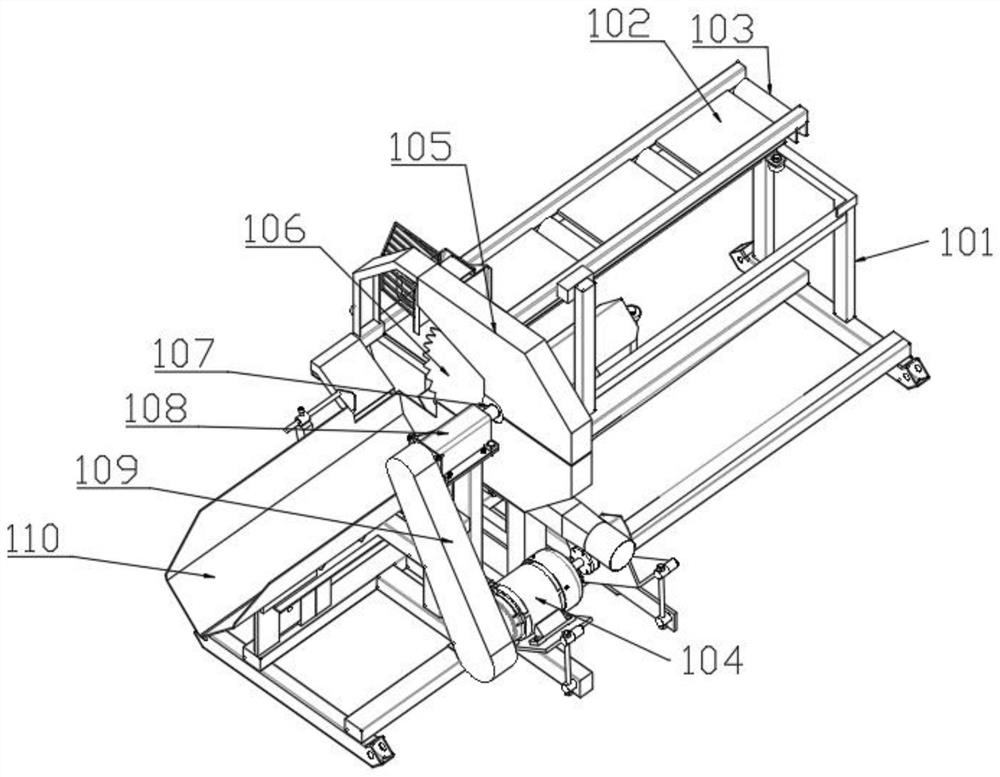

[0055] see Figure 1-8 As shown, a V-groove wood veneer bending forming process is provided in this embodiment, including: step 1, processing wood: placing unprocessed wood on a log cutting machine 1 for processing;

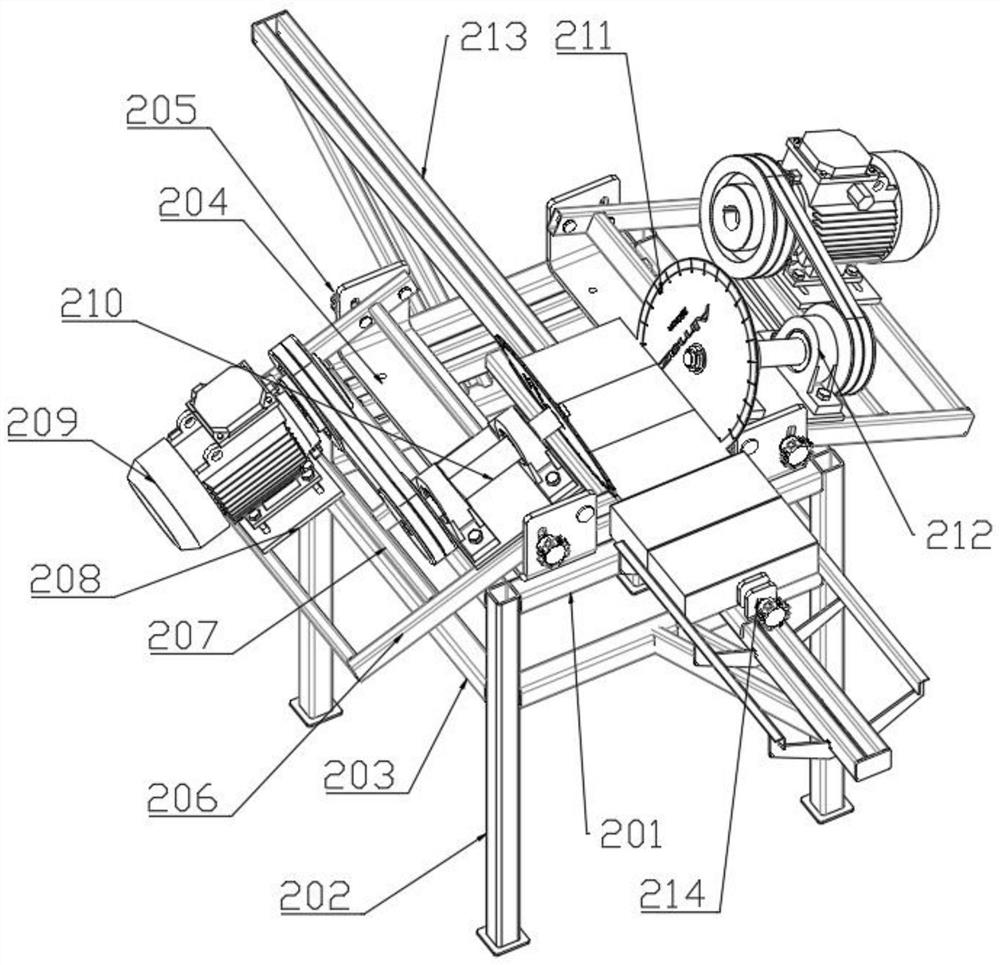

[0056] Step 2, wood slicing: place the processed wood on the slice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com