Construction method for light tube non-prestress hollow floor system

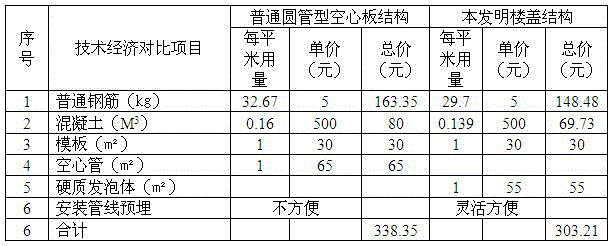

A non-prestressed, hollow-core floor technology, applied to floors, building components, buildings, etc., can solve the problems of construction restrictions, floor self-heaviness, and affecting building spans, and achieve simple construction and installation, high earthquake resistance, and increased Effect of Structural Span and Plane Bay Dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

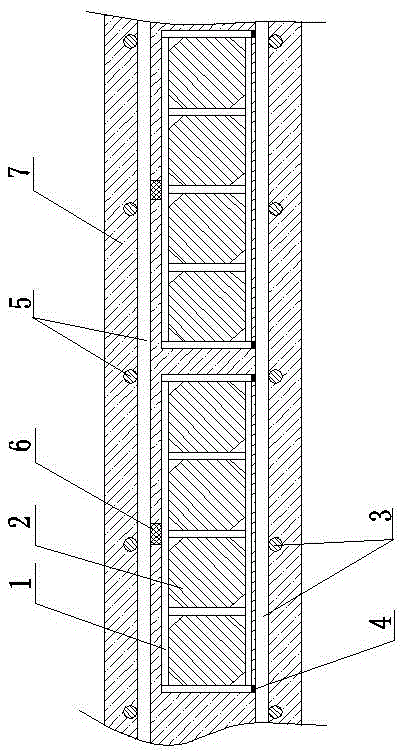

[0031] Construction example: A project in Ningxia: construction area 20875㎡, frame 5 floors, designed hollow floor area of about 9493㎡ (of which: 1st floor 3173.22㎡, second floor 2787.74㎡, third floor 476.21㎡, fourth floor 1766.03㎡, fifth floor floor 1289.8㎡), the strength grade of the hollow slab concrete is C30, and the structural slab thickness of the hollow slab is 260mm. The design adopts the lightweight tube non-prestressed hollow floor structure technology of the present invention.

[0032] Key points of process operation:

[0033] 1. Make the foam combination plate: use steel bar welding to arrange four hard foam steel grids in parallel, and assemble the same shape of hard foam in the steel grid to form a number of foam combinations plates.

[0034] Among them, the rigid foam can be made of polystyrene foam material, its cross-section is square or hexagonal, the width, thickness and length are 210 mm, 150 mm and 1000 mm respectively, and it is formed by 4 rigid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com