A method for forming multi-conductor parallel winding components

A winding element and molding method technology, which is applied in the field of molding multi-conductor parallel winding elements of aeronautical generators, can solve the problem of imperfect manufacturing technology of multi-conductor parallel winding elements, difficulty in meeting the motor's requirements for winding embedded wires, and poor separation of conductors. It is easy to popularize and apply, improve the insulation performance and heat dissipation of the end, and the overall shape consistency is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

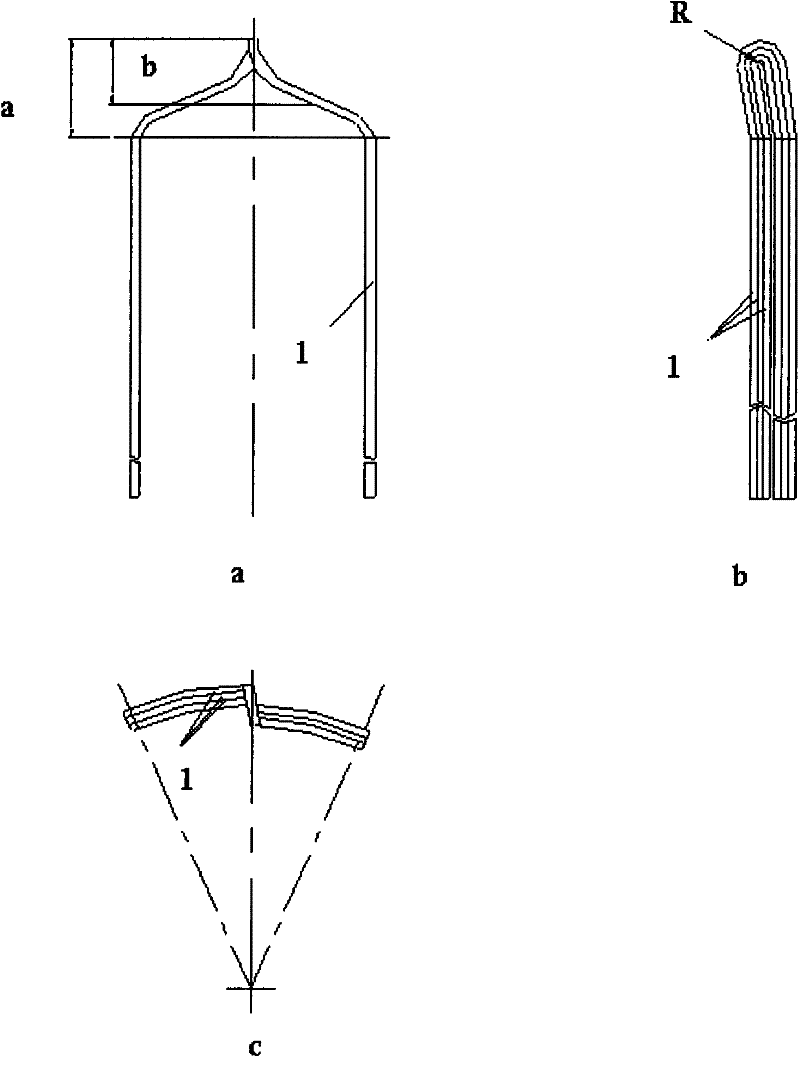

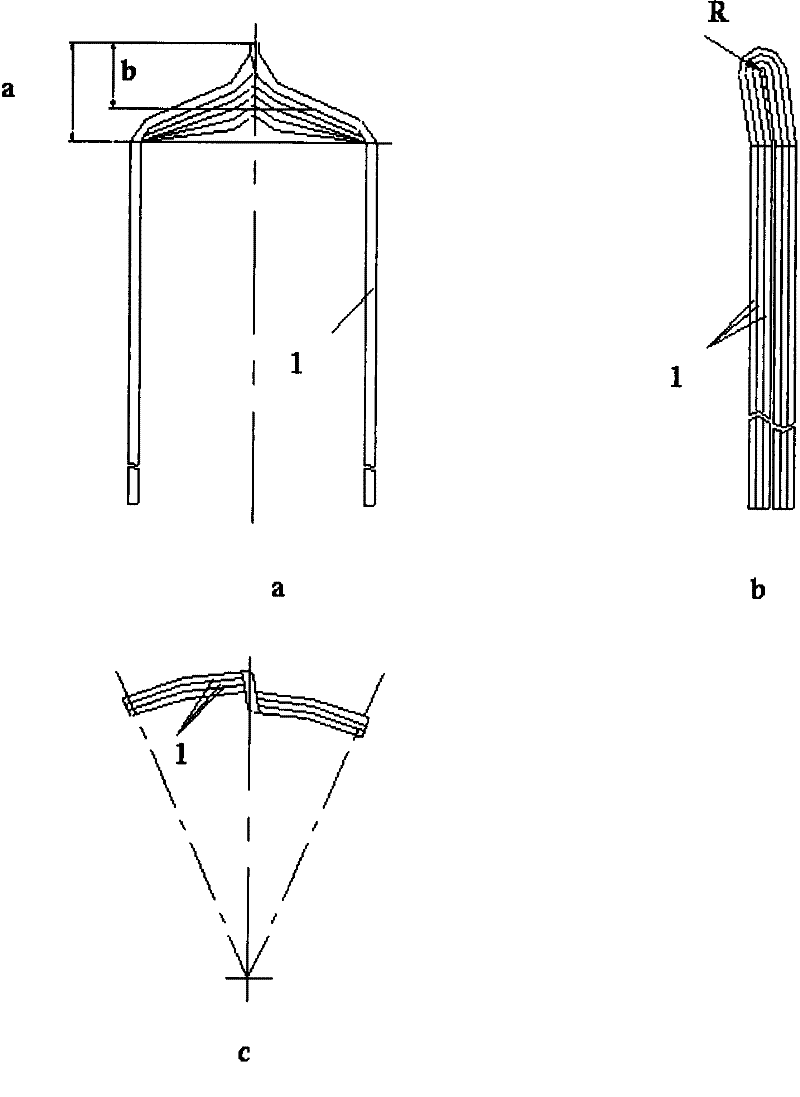

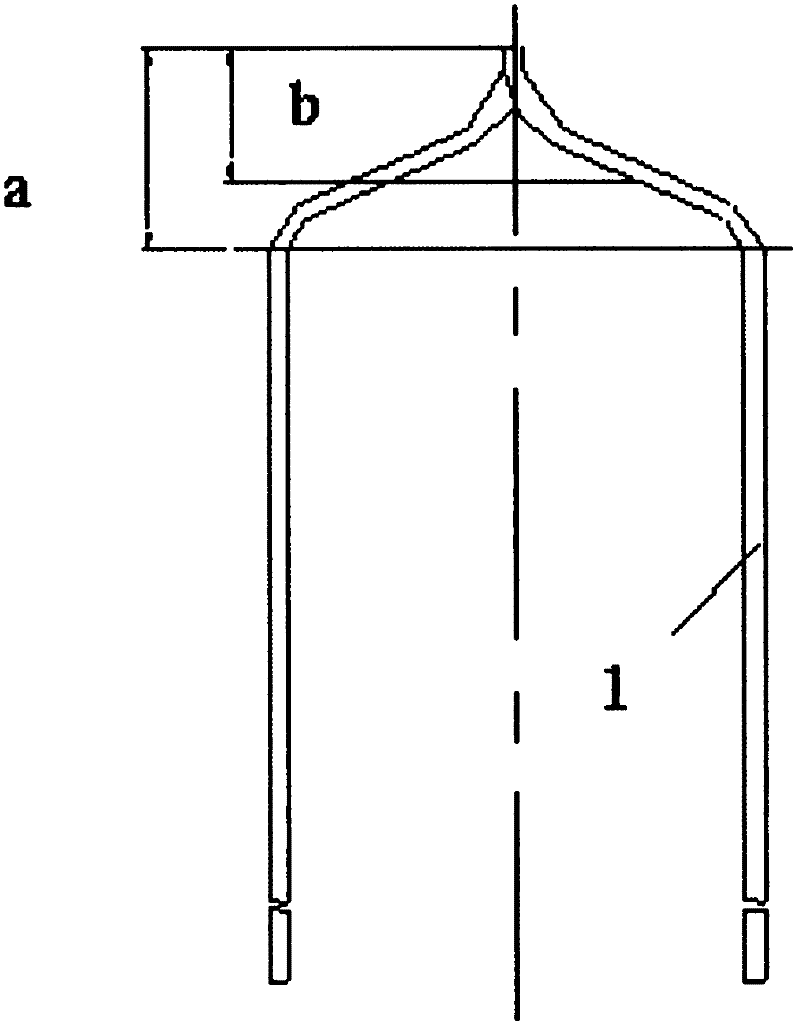

[0023] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0024] A main generator stator assembly of a 60kW alternator, the winding of which uses 54 pieces of QYB-2 / 220 polyimide enamelled flat copper wires to form a parallel winding element composed of three parallel winding elements, each conductor The specification of the element is 1.6X2.36, and the process method of the present invention is adopted for the three-conductor parallel winding element in the actual production of the aviation generator:

[0025] Step 1: Select QYB-2 / 220 polyimide enamelled flat copper wire according to the material required by the drawing of the motor winding component, and cut the material according to the size L=680mm and the quantity of 162 pieces;

[0026] Step 2: Grind rounded corners at both ends of a single wire, remove burrs, and then straighten;

[0027] Step 3: Connect 3 single wires in parallel, and use insulating 92 tape to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com