Novel package substrate and manufacturing method thereof

A technology for encapsulating substrates and manufacturing methods, which is applied in the fields of printed circuit manufacturing, multilayer circuit manufacturing, and photodevelopable thick films, etc., which can solve the problems of time-consuming and labor-intensive, high viscosity of glue, etc., so as to improve production efficiency and improve development Groove speed, convenient and quick effect of removing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Such as Figure 1 to Figure 6 As shown, it is a manufacturing method of a novel package substrate according to the present invention, comprising the following steps:

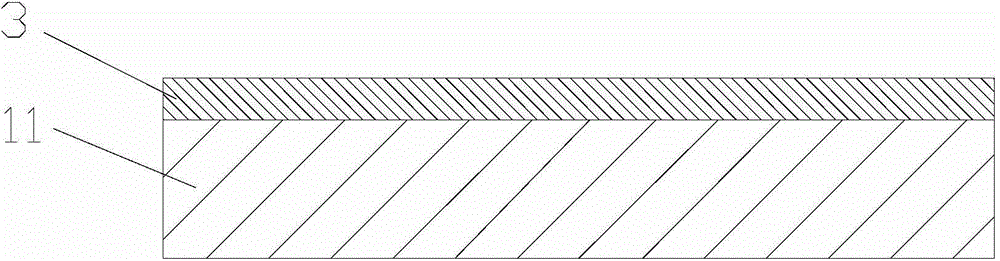

[0032] a. If figure 1 As shown, the first photosensitive dry film 3 is pasted on the upper surface of the first flame-resistant material plate 11 .

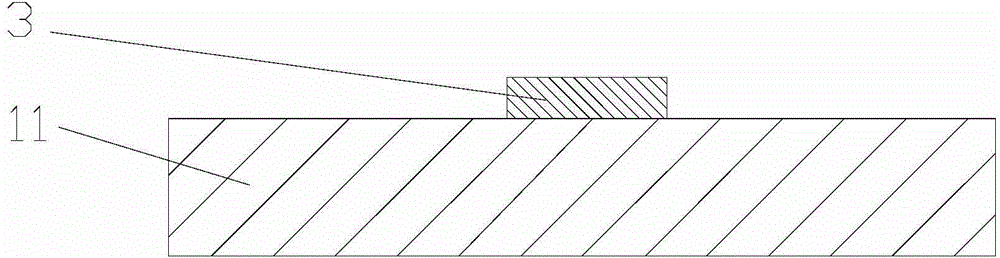

[0033] b. If figure 2 As shown, the first photosensitive dry film on the first flame-resistant material plate other than the predetermined groove position is removed by exposure and development.

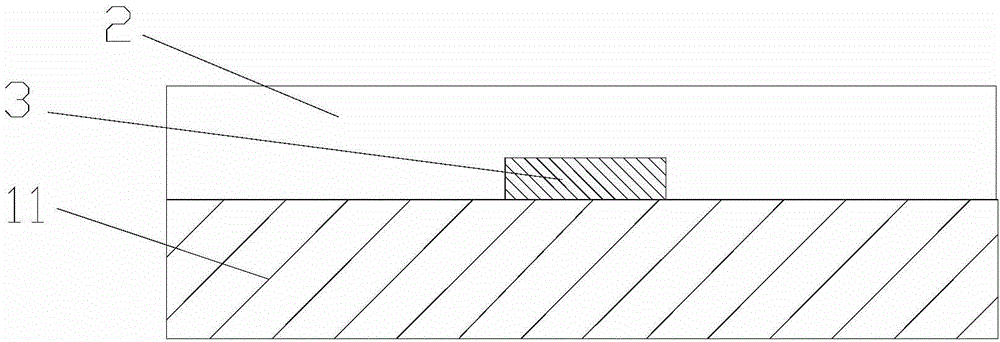

[0034] c. If image 3 As shown, a layer of P sheet substrate 2 is adhered on the upper surface of the first flame-resistant material plate 11 and the remaining first photosensitive dry film 3 .

[0035] d. If Figure 4 As shown, a second flame-resistant material plate 11 is bonded on the P sheet substrate.

[0036] e. If Figure 5 As shown, laser cutting is carried out from the upper surface of the second flame-resistant material plate 11 along the circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com