Shear type slotting machine

A slotting machine and scissors-type technology, applied in the field of scissor-type slotting machines, can solve the problems of inability to slot, difficult and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

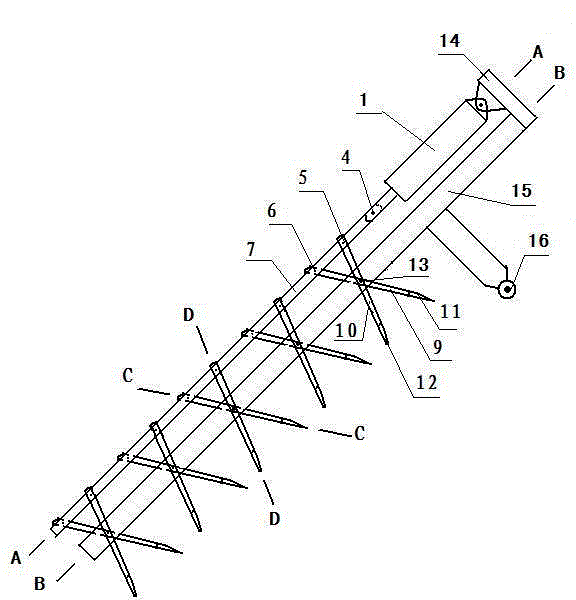

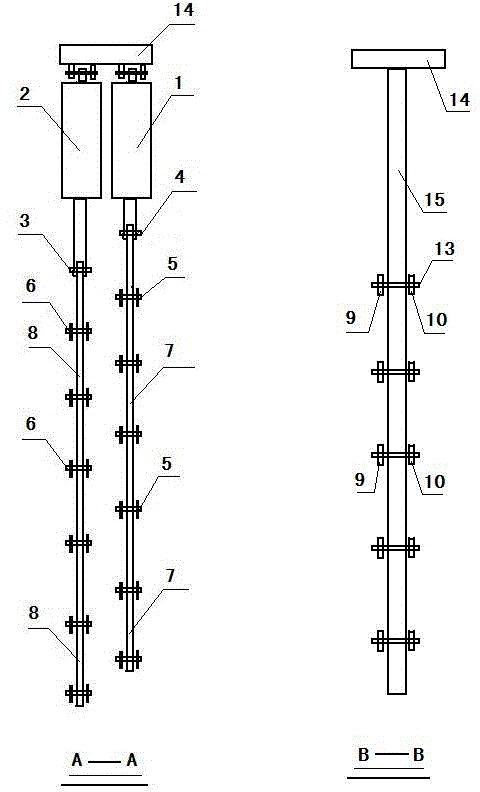

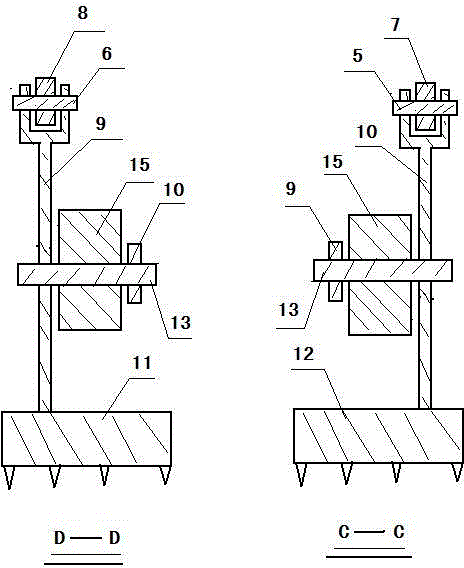

[0013] The accompanying drawing is a specific embodiment of the present invention. In this embodiment, the support shaft 16 is fixed on the support rod 15. The upper end of the telescopic oil cylinder A1 is hinged to the baffle plate 14, and the output shaft at the lower end is hinged to the transmission rod A7 through the pin shaft A4. The upper end of B2 is hinged to the baffle plate 14, and the output shaft at the lower end is hinged to the transmission rod B8 through the pin shaft B3; a pin shaft C5 is arranged at a certain distance on the transmission rod A7, and the pin shaft C5 hinges the upper end of each knife arm A10 to the transmission rod On A7, a pin shaft D6 is provided at a certain distance on the transmission rod B8, and the pin shaft D6 hinges the upper end of each knife arm B9 on the transmission rod B8; the middle of the knife arm A and the middle of the knife arm B pass through the pin shaft E13 Pinned to the support bar, one knife arm A and one knife arm B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com